Large Single Roll Crusher divinechannel

The single roll crusher reduces large size particles in the feed to a medium size while producing a considerably lower percentage of fines than other crushers 2 The single roll design is much more effective in reducing slabby material in comparison to jaw or gyratory crushers Pennsylvania Crusher brand single roll crushers are available in a variety of models: •Type K – suited for the size reduction of materials having a compressive strength of 8,000 psi or less Materials crushed typically include coal, petroleum coke, lignite and other friable substancesSingle Roll Crushers TerraSource APPLICATION Single Roll Crusher is an ideal primary breaker for crushing ROM coal, soft to hard limestone, ores, etc They can be built in large sizes to handle high capacities and runofmine large lumps OPERATING PRINCIPLE The crushing rings on the rotor crush the material by piercing and pressing the material against the breaker plateSingle Roll Crusher McNally Sayaji

Roll Crusher Manufacturer Design Williams Crusher

Large Single Roll Crushers How Roll Crushers Work Roll Crushers are simple in design and construction, longlasting, economical, and versatile across many applications and industries A combination of impact, shear, and compression are the forces necessary to perform the crushing and size reduction in a Williams roll crusherCrusher Roll drum is a heavily built and is keyed on a large steel shaft Renewable cast manganese steel crushing segments are bolted to the drum Single roll crusher is equipped with segments having long feeder teeth at proper intervals and various shaped short teeth covering the entire surfaceSINGLE ROLL BREAKER SUR IRON STEEL CO (P) LTD Triple Roll Crushers Triple Roll Crushers are ideal for producers who want to accomplish two stages of reduction in one pass They can be used in coal, salt, coke, glass, and trona operations, among others Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher Roll Crushers McLanahan

Roll Crusher an overview ScienceDirect Topics

Roll Crusher For a given reduction ratio, singleroll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass, depending upon the top size of the feed coal Doubleroll crushers consist of two rolls that rotate in opposite directions The sledging type of either single or doubleroll arrangement is usually differentiated by such titles as “ roll crusher ” or “sledging rolls” The only point of similarity in the actions of the crushing rolls and the gyratory and jaw types is that both do their crushing Rolls Crusher for Sale 911 Metallurgist High reduction rate and large capacity Roll crushers have a theoretical MAXIMUM reduction ratio of 4:1 If a 2inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inch Roll crushers can adjust Roll Crusher With stable Performance Fote

Single Roll Crushers Acan Machine

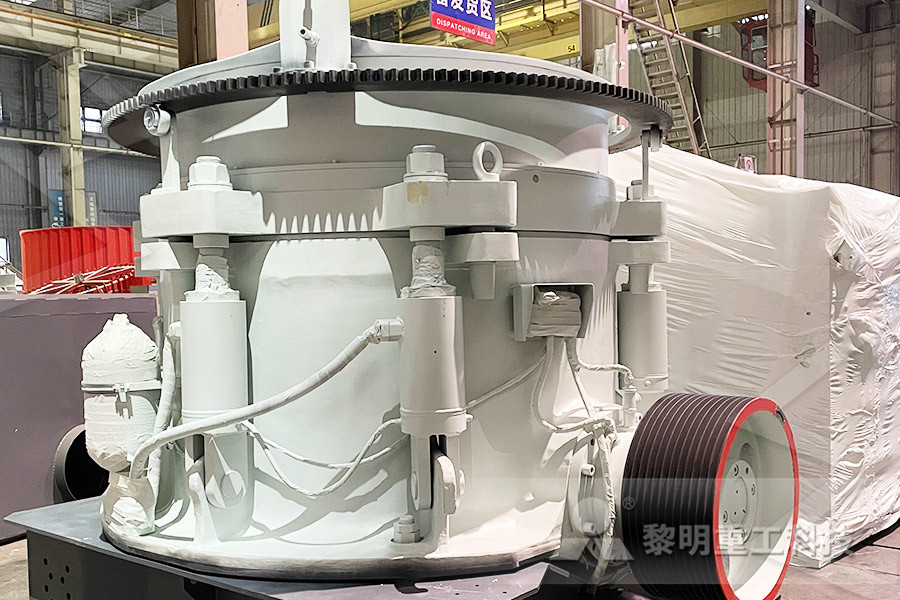

Single Roll Crushers are primary crushers that provide a crushing ratio They reduce materials such as coal, mine refuse, shale, slate, gypsum, bauxite, salt, soft shale, etc, from large size particles to a medium size, while producing minimal finesThe single toothed roll crusher that we manufacture is actually a rotary roller which consists of a large tooth and also a crushing plate which is adjustable according to the need and requirement The material that is fed into the single roll crusher is smashed first and then pressed from inside of the single tooth roll breaker followed by Ecoman Single Roll Crushers, Ecoman ID: A wide variety of single roller crusher options are available to you, such as none, egypt, and philippines You can also choose from competitive price, long service life, and high productivity As well as from energy mining, building material shops, and construction works And whether single roller crusher is 1 year, 2 years, or 15 yearsChina Single Roller Crusher, China Single Roller

SINGLE ROLL BREAKER SUR IRON STEEL CO (P) LTD

Crusher Roll drum is a heavily built and is keyed on a large steel shaft Renewable cast manganese steel crushing segments are bolted to the drum Single roll crusher is equipped with segments having long feeder teeth at proper intervals and various shaped short teeth covering the entire surfaceTriple Roll Crushers Triple Roll Crushers are ideal for producers who want to accomplish two stages of reduction in one pass They can be used in coal, salt, coke, glass, and trona operations, among others Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 6:1 reduction ratio in the primary stage and a 4:1 reduction Roll Crushers McLanahanRoll Crusher For a given reduction ratio, singleroll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass, depending upon the top size of the feed coal Doubleroll crushers consist of two rolls that rotate in opposite directionsRoll Crusher an overview ScienceDirect Topics

Roll Crusher With stable Performance Fote

Advantages of roll crusher High reduction rate and large capacity Roll crushers have a theoretical MAXIMUM reduction ratio of 4:1 If a 2inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inch The nip angle is defined as the angle that is tangent to the roll surface at the points of contact between the rolls and the particle It depends on the surface characteristics of the rolls Usually, the nip angle is between 20° and 30° but in some large roll crushers it is up to 40° 621 Roll crusher Roll Crushers ScienceDirectThe Single Roll Crusher, with its 6:1 ratio of reduction, is ideal for reducing large feed lumps to a medium product size while producing a considerably lower percentage of fines The minimum product sizing of a Single Roll Crusher is generally limited to 23 The crushing is carried out between the full width of the extralong curved crushing roller crusher roll crusher double roll crusher single

Home Eagle Crusher

Eagle Crusher started as a family business with a rich heritage going back more than 100 years Eagle is still a familyowned business today, operating from that same rich heritage A heritage that puts customers first, and treats you like you’re one of the family, with unsurpassed service and support, long after the sale, to make your job Single Roll Crushers are primary crushers that provide a crushing ratio They reduce materials such as coal, mine refuse, shale, slate, gypsum, bauxite, salt, soft shale, etc, from large size particles to a medium size, while producing minimal finesSingle Roll Crushers Acan Machine The single toothed roll crusher that we manufacture is actually a rotary roller which consists of a large tooth and also a crushing plate which is adjustable according to the need and requirement The material that is fed into the single roll crusher is smashed first and then pressed from inside of the single tooth roll breaker followed by Single Roll Crusher Manufacturers and Exporters India

Roll Crusher an overview ScienceDirect Topics

Roll Crusher For a given reduction ratio, singleroll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass, depending upon the top size of the feed coal Doubleroll crushers consist of two rolls that rotate in opposite directionsThis is basically a Double Roll Crusher with crushing elements called spikes, of different shapes / sizes to meet different applications The crushing element is fixed to individual spike holders, which are keyed to the roll shaft Thus crusher can handle large feed sizes and crush creating minimum finesRoll Crusher Machine Single Roll Crusher The Lancaster Products Roll Crusher is a compact unit built around a rigid cast frame It is powered by a VFD gear drive unit The high alloy steel shafts are driven by a heavyduty chain operating in an enclosed oil bath All parts coming in contact with the process material are replaceable and are made of Lancaster Products Roll Crusher for Glass

Roller Crusher Single/Double Roll Crushers JSXC Mine

Types of Roll Crushers Stone roll crusher can be divided into singleroll, doubleroll and multiroll several types according to the number of rollers According to the shape of the roll surface, have two kinds, smooth roll and tooth roll The former is suitable for The nip angle is defined as the angle that is tangent to the roll surface at the points of contact between the rolls and the particle It depends on the surface characteristics of the rolls Usually, the nip angle is between 20° and 30° but in some large roll crushers it is up to 40° 621 Roll crusher Roll Crushers ScienceDirectThe Single Roll Crusher, with its 6:1 ratio of reduction, is ideal for reducing large feed lumps to a medium product size while producing a considerably lower percentage of fines The minimum product sizing of a Single Roll Crusher is generally limited to 23 The crushing is carried out between the full width of the extralong curved crushing roller crusher roll crusher double roll crusher single

Double Roll Teethed Roll Crusher 911 Metallurgist

The singleroll crusher has a tip speed of 400450 ft/min while the 6 x 7ft teethed roll crusher has a normal, noload, surfaces speed of just under 3500 ft/min It can be readily appreciated that this high velocity induces an extremely violent crushing action, in conjunction with the 3 to 4in knobs which protrude from the roll surfaces Roll faces carry corrugations, breaker bars, or teeth Contains 2 rolls as in smooth roll crusher or one roll acting against stationary curved breaker plate Machine shown in a figure is single roll toothed crusher Machines known as disintegrators contain two corrugated rolls turning at two different speeds which tear the feed apartSize Reduction Equipment BIT Mesra