metal sheet metal grinding process automation

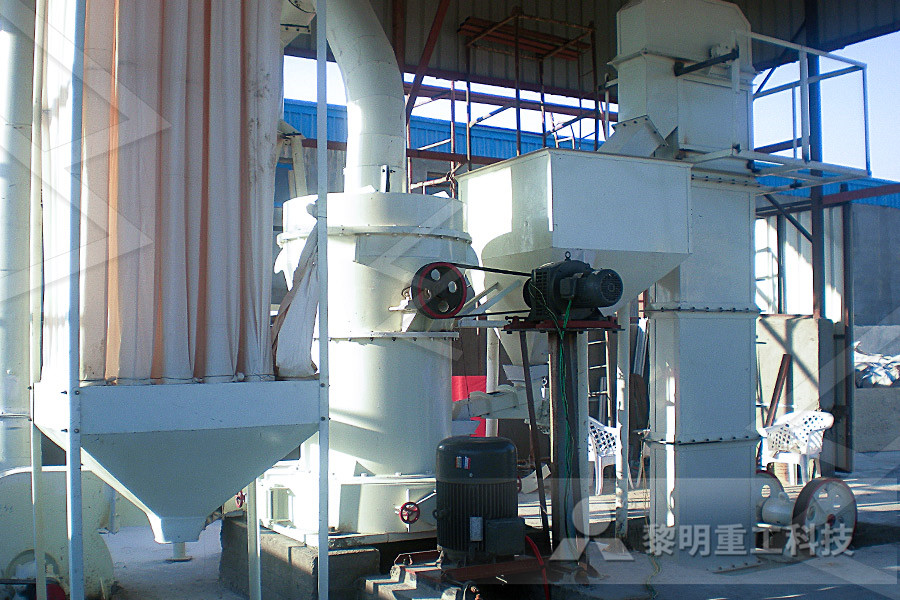

Sheet metal grinding system :: Applications :: Solution :: Motorcon In the sheet metal processing process, there will be protrusions at the weld, which need to be polished and smoothed The traditional method is to manually grind the device by hand, but labor intensity is high, and the dust and noise generated by the process may affect healthAutomating your entire sheet metal manufacturing process using tailored solutions is very simple In a dedicated fabricating cell containing tending robots, plates can be cut, folded and processed, with workpieces travelling between welding and grinding stations on a conveyorAutomate sheet metal production FanucSheet metal deburring with boeck’s tools Our tools improve your „sheet metal deburring“ process The tools are for slag and oxide removal, deburring and rounding of edges, and surface finishing Injuries hazards can be reduced on sharp sheet metal edges, large edgerounding for a perfect coating or decorative surfaces can be achievedMetal sheet metal deburring with grinding and

Sheet metal fabrication: How automation strengthens

Sheet metal working companies are often anchored in tradition and many processes are still done by hand However, price consciousness is increasing and the era of Industry 40 poses new challenges In this article you will learn how the automation of sheet metal Grinding is a large and diverse area of sheet metal manufacturing It can produce very fine finishes and very accurate dimensions; yet in mass production contexts it can also rough out large volumes of metal quite rapidly It is usually better suited to the machining of very hard materials than is “regular” machining (that is, ContinuedMetal Grinding Artmetco Sheet Metal Manufacturing At every process upstream, most precision sheet metal fabricators employ at least some level of automation But there’s no getting around it: Grinding down a weld on a formed workpiece is and probably will remain an intensely manual operation The act of grinding can be deceivingly simple But the devil’s in the detailsEight tips for effective grinding The Fabricator

Sheet metal processing TRUMPF

Switching cabinet housing, plugin units, and the housing of electrical devices – all of these are created from sheet metal designs TRUMPF laser cutting, punching, and bending machines can process these components – which are often very complex and made from thin sheet with numerous bends Designed as a standard solution for numerous STUDER OD and ID grinding machines, the flexLoad offers truly impressive boosts to productivity and efficiencyHighProduction Grinding With flexLoad Automation It caters for an accurate axis motion for a precise performance and enhanced surface finish, allows for unmanned operation—being a fully automated solution—and has the flexibility to different tools, spindle power and automation capacity while providing high levels of speed and productivity and a long machine tool life APMEN Metal Let’s Get Grinding Manufacturing Automation

Timesavers Series 42RB Grinding and Deburring

The standard version includes; a centrally installed and user friendly control panel, an automatic table opening of 0 – 100 mm, Carrousel rotating brush head equipped with 4 brushes rotating to the left and 4 to the right, a frequencycontrolled conveyor belt with a speed ranging from 02 to 8 m/min, window panels and lit interior for process Sheet metal grinding system :: Applications :: Solution :: Motorcon In the sheet metal processing process, there will be protrusions at the weld, which need to be polished and smoothed The traditional method is to manually grind the device by hand, but labor intensity is high, and the dust and noise generated by the process may affect healthmetal sheet metal grinding process automation All systems are inhouse developed and planned, including both the mechanical aspect and the electric and robot/PLC programming part Industrial robotics connected to the specific field of sheet metal processing makes the customer selfsufficient in terms of process management, increasing their professionalism and engendering staff satisfactionIndustrial Automation: plants for the processing of

Sheet Metal Fabrication Process Enclosure Fabrication

Grinding is the process where the grain hits the metal Most precision sheet metal fabricators employ at least some level of automation Grinding down a weld on a metal piece is and probably will remain an intensely manual operation parts, Turning, drilling, grinding, Milling, Sheet metal View More RESTART automation milling, turning, casting, stamping, extrusion comprehensive machining process service Machining 3 4 axis 1200*600mm max machining area Turning Domore Precision HomeAutomation, speaking in a very general way, tends to bring increased production speed and increased repeatability to the sheet metal welding process Manual welding has the benefit of relatively easy and flexible setup; an experienced welder can begin working on a new assembly much faster than a robot that must be programmedWhen (and How) to Automate Sheet Metal Welding

Metal Grinding Artmetco Sheet Metal Manufacturing

Grinding is a large and diverse area of sheet metal manufacturing It can produce very fine finishes and very accurate dimensions; yet in mass production contexts it can also rough out large volumes of metal quite rapidly It is usually better suited to the machining of very hard materials than is “regular” machining (that is, ContinuedSheet metal deburring with boeck’s tools Our tools improve your „sheet metal deburring“ process The tools are for slag and oxide removal, deburring and rounding of edges, and surface finishing Injuries hazards can be reduced on sharp sheet metal edges, large edgerounding for a perfect coating or decorative surfaces can be achievedMetal sheet metal deburring with grinding and LOS Automation doo Platiseva ulica 37, SI – 5282 Cerkno VAT Number: SI Company ID: IBAN: SI56 0400 1004 9196 449 (Nova KBM dd) E: info@losautomationMetal processing LOS Automation

Metal Brushing Machine For Flexible Sheet Metal

APT provides the best surface cleaning and finishing process technology that includes metal brushing machine, flexible sheet metal, processing lines for Sheet Metal 2D Laser Cutting; 3D Laser Cutting; The Siemens control is installed at a 45° angle for a clear view of the machining process, ensuring this machine is ergonomic in its design and easy to operate around for a long time, since 1949 We have caring family values and are embracing the future with IoT, Industry 40 Timesavers Series 32RB Grinding and Deburring Sheet metal grinding system :: Applications :: Solution :: Motorcon In the sheet metal processing process, there will be protrusions at the weld, which need to be polished and smoothed The traditional method is to manually grind the device by hand, but labor intensity is high, and the dust and noise generated by the process may affect healthmetal sheet metal grinding process automation

Sheet Metal Fabrication Process Enclosure Fabrication

Grinding is the process where the grain hits the metal Most precision sheet metal fabricators employ at least some level of automation Grinding down a weld on a metal piece is and probably will remain an intensely manual operationAutomation, speaking in a very general way, tends to bring increased production speed and increased repeatability to the sheet metal welding process Manual welding has the benefit of relatively easy and flexible setup; an experienced welder can begin working on a new assembly much faster than a robot that must be programmedWhen (and How) to Automate Sheet Metal WeldingRobotic sanding, robotic grinding, and other finishing and material removal jobs can be dangerous and pose serious hazards to people’s health and safety Plasma Cutting Robot for Sheet Metal Courtesy of Shape Process Automation Robotic Metal Plasma Cutting System Courtesy of ARC Specialties SteelPRO 900 Robotic Plasma Cutting Robotic Cutting, Deburring, Polishing, Grinding,

Timesavers Series 32RB Grinding and Deburring

Sheet Metal 2D Laser Cutting; 3D Laser Cutting; The Siemens control is installed at a 45° angle for a clear view of the machining process, ensuring this machine is ergonomic in its design and easy to operate around for a long time, since 1949 We have caring family values and are embracing the future with IoT, Industry 40 Precision Metal Fabrication Equipment and Manufacturing Automation complex tool layouts The automatic Tool Changer can load the most complex tool layout within minutes For precision sheet metal forming, the integrated bend sensor guarantees consistent bend angle accuracy for ZERO DEFECTS production seamless integration process of Precision Sheet Metal Equipment > Versatility ToolWe process sheet metal in gauge sizes that range from 26 GA to ½” with a maximum sheet size of 600″ in width x 1440″ in length Material choices are numerous — we fabricate parts and assemblies from all types of metal, including highperformance gradesSheet Metal Fabrication JE Companies

Sheet Metal Forming Machines, Sheet Metal Cutting

Sheet Metal Forming Machines And Sheet Metal Cutting Machines Manufacturer: FORMING CUTTING APPLICATION TOOL TECH SPM designs and manufactures standard and customized metal forming as well as cutting equipment, and provides its services for the production of formed parts Deburring edges is essential in modern sheet metal processing in order to produce reliable and high quality parts Deburring machines reliably remove any burrs left on the parts and help to ensure that the downstream processes function smoothlyFind out more about the sheet metal deburring process and discover why deburring makes sense for your companySheet Metal Deburring Why Use Sheet Metal Various developments inside the sheet metal industry and influences from outside the industry, make product edge rounding / radiussing increasingly important Radiussing up to 2 mm Such as, for example coating or painting requirements, food safety requirements and in Edge rounding Edge rounding of sheet metal