how is stibnite ore processed Induzin

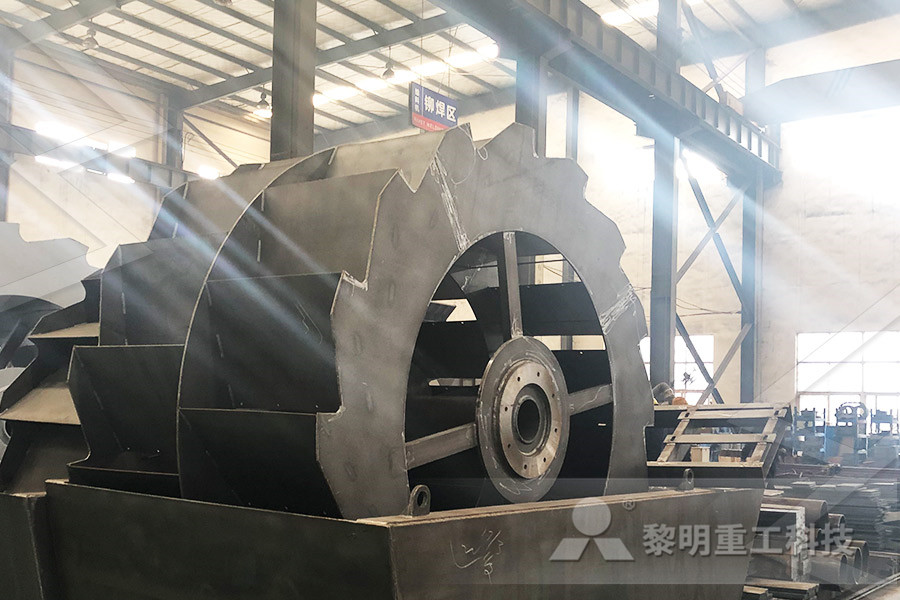

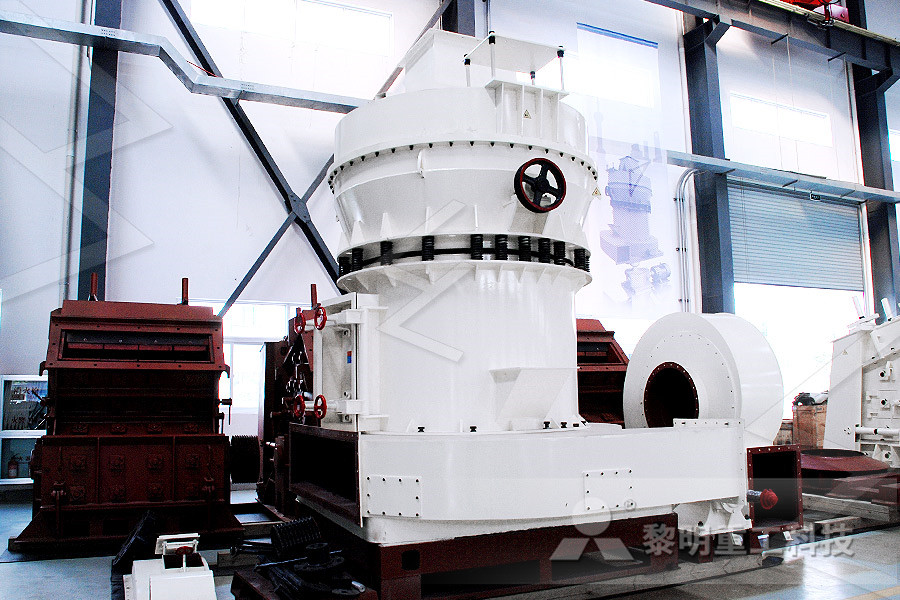

stibnitefroth flotation a critical review sciencedirect Mar 15, 2021 Zhou et al (2020) report that for every ton of stibnite ore processed in the flotation circuit at the Xikuangshan Antimony Mine in Hunan, China, 35 m 3 of water are consumed, while producing 920 kg of tailings and 02 kg of dust how is stibnite ore processed in mexico We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other how is stibnite ore processed in mexicostibnite ore beneficiation equipment to get Gravity separation of stibnite antimony can be adopted in concentration of most of Antimony Ores Stibnite is a sort of coarse particles minerals with big density, so process antimony separation

Stibnite an overview ScienceDirect Topics

Johanna Feary, Paul Cullinan, in Reference Module in Biomedical Sciences, 2019 Production and sources of exposure Antimony is a metalloid which occurs mainly as the sulphide mineral stibnite (antimony trisulphide Sb 2 S 3) in metamorphic deposits in granites and limestoneWorldwide, the greatest producer of antimony is China followed by Russia and Bolivia Stibnite is a material added by GregTech 5 mod Stibnite is a Steamtier material It can to be processed in MVtier Electrolyzer in order for its chemical components to be obtained It can also be smelted in any furnace, which converts it into Antimony Ingot in 1:1 ratio from dust, which is more efficient Finally, smelting it in Bricked Blast Furnace Bricked Blast Furnace, Bronze Plated Stibnite (GregTech 5 Material) Feed The Beast Wiki The crude ore (reduced to pieces of about the size of a nut but not into powder) is placed in a crucible having a hole of 5 mm of diameter at its bottom A metallic wirenetting is placed around the crucible Acting as a screen, it will "break" the flames The extraction of Antimony from its ore LEVITY

Stibnite Creek (ARDF #TC029) Au, Sb USGS

The Tok Antimony deposit, also called Boulder Creek, Stibnite, A Lucky Leak, and Stibnite Creek, was discovered in the early 1900s A 12foot adit was driven in 1914 In 1940, several tons of ore from the prospect were stockpiled by Boulder Creek awaiting transportAntimony is sometimes found in pure form It is also obtained from the mineral stibnite (antimony sulfide) and commonly is a byproduct of leadzincsilver mining Other antimonybearing minerals include sibiconite, tetrahedrite and ullmannite It is mined in China, Bolivia, South Africa and MexicoAntimony Minerals Education Coalition Stibnite Gold Project Plan of Restoration and Operations 10 r4 1012 Crushing The crusher will break the ore into smaller pieces to a consistent diameter of approximately seven inches or less (Section 172 includes a photo of a typical jaw crusher) The run rof rmine ore will be10 ORE PROCESSING Perpetua Resources

THE STIBNITE GOLD PROJECT

At the Stibnite Gold Project, we will use a weak sodium cyanide solution to extract gold from the ore we mine Cyanide has a natural tendency to bond with metals, even when they occur in microscopic amounts, such as gold and silver in ore This method of gold recovery has been popular for over a century Advances in technology have allowedStibnite, primarily a Sb 2 S 3 ore that belongs to the orthorhombic system (a 0 = 1120 Å, b 0 = 1128 Å, and c 0 = 383 Å), has been found as huge crystals and a crystal cluster (chemical purity: 99% Sb 2 O 3) in many areas around the globe 25,26 In addition, stibnite is a significant raw mineral material used to obtain antimony and Natural stibnite ore (Sb 2 S 3 ) embedded in sulfur Mining at the Stibnite Gold Project would be accomplished using conventional open pit hard rock mining methods Mining is planned to deliver 805 Mst of ore to the crusher per year (22,050 st/d), with stockpiling by ore type (low antimony sulfide, high antimony sulfide and oxide)Major Mines Projects Stibnite Project

Ore vs Stibnite What's the difference? WikiDiff

As nouns the difference between ore and stibnite is that ore is rock that contains utilitarian materials; primarily a rock containing metals or gems which—at the time of the rock's evaluation and proposal for extraction—are able to be separated from its neighboring minerals and processed at a cost that does not exceed those materials' presentday economic values while stibnite is Stibnite Gold Project, Idaho The ore will undergo crushing, milling and treatment using the sequential flotation method The recovered antimony is intended to be shipped to a third party, while the resultant gold sulphide concentrate will be processed onsite using pressure oxidation (POX), complemented by agitated tank leaching to produce Stibnite Gold Project, Idaho Mining Technology Stibnite becomes sufficiently liberated for recovery through selective antimony flotation Cutoff determination utilized a net smelter return methodology to account for varying ore types and separate process streams with unique process costs Antimony concentrate Yellow Pine 7 909 94,258 Hangar Flats 3 313 21,150 Historical tailings 1 Get priceseparate antimony from a stibnite concentrate

Process for preparing high purity antimony trichloride

Antimony sulfide contained in an antimony sulfide bearing ore, such as stibnite, is converted to high purity antimony trichloride by reacting the antimony sulfide bearing ore with a source of chlorine to form high purity antimony trichloride and sulfur or hydrogen sulfide as separable byproductsMAR 2019 separation of lead from stibnite ore by floatation separation of lead from stibnite ore by floatation how lead is madematerial, used, processing, product, industry , therefore much lead ore is obtained as a byproduct of other metal mining at the end of the flotation process, the lead has been separated from the rock and separation of lead from stibnite ore by floatation This study investigated the leaching and electrowinning of antimony from a complex, high arsenic and goldcontaining stibnite concentrate ore (AsAuSb ore) using slurry electrolysis (SE) The results indicated that the leaching efficiency of antimony was higher than 98%, and those of iron and arsenic were about 550% and 114%, respectivelyExtracting antimony from high arsenic and gold

Natural stibnite ore (Sb 2 S 3 ) embedded in sulfur

Stibnite, primarily a Sb 2 S 3 ore that belongs to the orthorhombic system (a 0 = 1120 Å, b 0 = 1128 Å, and c 0 = 383 Å), has been found as huge crystals and a crystal cluster (chemical purity: 99% Sb 2 O 3) in many areas around the globe 25,26 In addition, stibnite is a significant raw mineral material used to obtain antimony and At the Stibnite Gold Project, we will use a weak sodium cyanide solution to extract gold from the ore we mine Cyanide has a natural tendency to bond with metals, even when they occur in microscopic amounts, such as gold and silver in ore This method of gold recovery has been popular for over a century Advances in technology have allowedTHE STIBNITE GOLD PROJECT Perpetua ResourcesAntimony sulfide contained in an antimony sulfide bearing ore, such as stibnite, is converted to high purity antimony trichloride by reacting the antimony sulfide bearing ore with a source of chlorine to form high purity antimony trichloride and sulfur or hydrogen sulfide as separable byproductsProcess for preparing high purity antimony trichloride

Refractory Gold Ore Treatment Methods 911

Stibnite (Antimony Sulphide, Sb2S2) This mineral in an ore acts as a weak acid, combining with alkalis to form salts, of the order of M1/3SbS2 and M1/3SbS4 alkaline sulphantimonite and sulphantimonate, especially in the presence of iron sulphides, using high concentrations of lime or alkalisstibnite are sold unprocessed as crude antimony ore (stibnite) Ores with a content of 4560% stibnite are processed by liquefaction because of the low melting point of stibnite Lowgrade ores are processed by flotation to obtain crude stibniteb Following extraction, this material is processed to antimony metalCRITICAL RAW MATERIALS PROFILESAntimony sulfide contained in an antimony sulfide bearing ore, such as stibnite, is converted to high purity antimony trichloride by reacting the antimony sulfide bearing ore with a source of chlorine to form high purity antimony trichloride and sulfur or hydrogen sulfide as separable byproducts The high purity antimony trichloride may be hydrolyzed to form high purity antimony oxideUSA Process for preparing high purity

Ore Processing Feed The Beast Wiki

Purified Ore doesn't give Stone Dust in this machine Basic Centrifuge can be used to obtain Dust from Impure Dust and from Purified Dust This also gives 1 Tiny Dust of byproduct, which is the same as for processing the Crushed Ore or Purified Ore of this material in Basic Thermal Centrifuge stibnite (antimony metal + source of antimony trioxide used as flame retardant) quartz (silicon metal + source of silica in glass, ceramics, fillers) There are also synthetic industrial minerals, which are manufactured from natural minerals Synthetic minerals are often processed owing to the inferior characteristics and/or scarcity of their What are industrial minerals? IndMin The mine is located in an area with welldeveloped infrastructure and is accessible by paved roads Fosterville’s ore is processed at the Fosterville Mill, a 2,275 tonne per day processing facilityKirkland Lake Gold Our Business Australia

[1122][TFC: Metallum——群峦金属拓展] 支持科技mod的

[1122][TFC: Metallum——群峦金属拓展] 支持科技mod的TFC更多金属生成! TFC: Metallum作者原文:[spoiler]TFC: Metallum is an addon for the official TerraFirmaCraft port to 1122+ that adds new ores , metals , tools and more to the mo