AG Autogenous Grinding 911 Metallurgist

Three stages of open circuit crushing were used to prepare rod mill feed Grinding media was selected from various areas of the mine and tested separately Impact tests on the three basic types of ore give Work Indices varying from 148 to 91 with two types Rely on our proven track record of SAG and AG Mill superiority Since the early 1980s, we have been designing and manufacturing SemiAutogenous (SAG) and Autogenous (AG) Grinding Mills under the FullerTraylor brand Semiautogenous grinding uses a minimal ball charge in the range of 615% while autogenous grinding uses ore Autogenous and SemiAutogenous Mills Semiautogenoussingle stage These circuits are not a good choice for many orebodies because it is not logical to expect one machine to be as efficient on 150 mm ore as it is on 100 micron ore Semiautogenous plus ball mill has been the “work horse” of mills SAG vs Ball Mill Advantages AG SAG Mill Grinding Autogenous Grinding Semi Autogenous Grinding

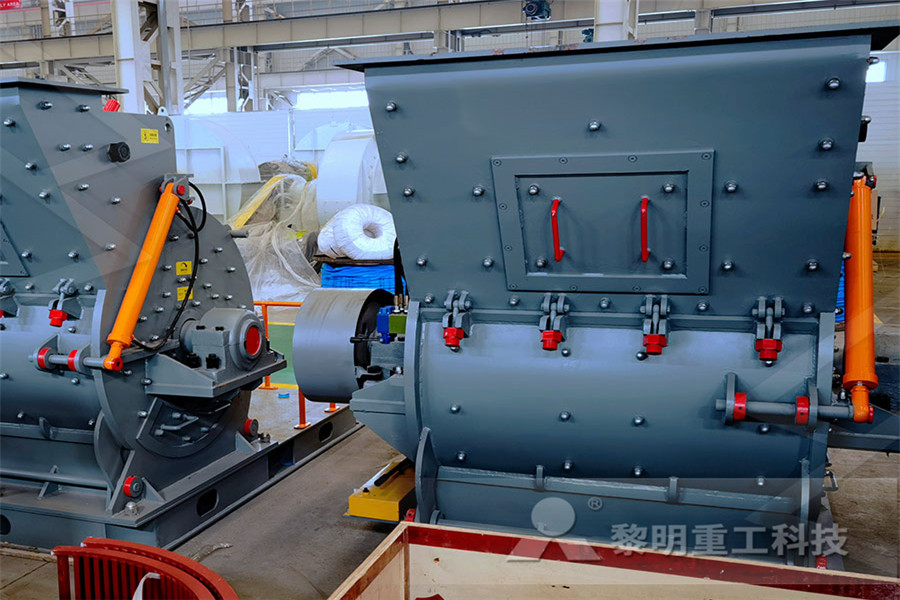

Mineral Grinding Mill Autogenous Grinding Mill

Ag Autogenous Grinding Ag autogenous grinding in conventional milling, the ore is crushed to, plus or minus, 38 of an inch, before it is put into a mill for grinding in a autogenous mill the ore is fed directly into the mill from either the primary crusher or the mine itself the Why is Ore Grinding Necessary In the three other types of mill a continuous supply and removal of the powder is maintained, and these methods are applicable to mills of the largest sizes Grate Discharge Mill In the grate discharge mill, Fig 14b, a diaphragm in the form of a grating confines the ball charge to one end of the mill Grinding Mills Common Types 911 Metallurgist Single stage semiautogenous / autogenous (S/AG) milling has become a common design for a variety of ore types with the advantages of being comparatively low capital cost and flexible for future expansion The single stage SAG/AG milling option is ideal for starter projects with significant exploration and expansion potential Currently aSINGLE STAGE SAG/AG MILLING DESIGN Orway

White paper, September 2015 SmartMill™: Exceed your

mills SAG mills of over 40foot diameter have been constructed Like the ball mill, the AG/SAG mill will have a critical rotation speed above which grinding ceases Mill motor types There are three common motor types that drive the grinding mills described above: – Gearless motors These variablespeed motors range up to 30 MW and have the AG/SAG mills as a primary grinding stage in a circuit with or without additional stages of comminution with different operator/advanced process control regimens required based on different ore types SAG Mill Circuit Sampling The original SAG mill control loop, a mill motor SAG Mill Grinding Circuit Design 911metallurgistRod mill is a kind of ore grinding mill with steel rod as grinding medium to grind materials Rod mill design for the fine and coarse grinding of various hardness of ore materials with wet process Compared with ball mills and vertical roller mills , rod mills process materials more delicately, and can be used in material grinding processes for Rod Mill with Good Price for Mining Industrial Ore

A Mechatronic Solution Design and Experience with Large

are capable of handling various ore and mill types Time has shown that all requirements for grinding mills can be satisfied by this concept In many cases, innovative solutions have been developed to provide considerable benefits for projects worldwide Functional Requirements The SAG mill is the heart of the concentrator autogenous grinding (AG) mill, ball mill and crusher An SABC circuit consists of a semiautogenous grinding (SAG) mill, ball mill, and crusher A ball mill is a slightly inclined, horizontal rotating cylinder, partially filled with ceramic balls, flint pebbles or stainless steel balls, that grinds material to theWhen it Comes to Mining, Bigger is BestMill application features Frozen charge protection – Detects frozen charge in the mill, minimizing equipment wear and liner replacements; Coupling supervision – Detects if a failure or slippage occurs in the couplings and stops the system in case, preventing major damages; Standstill detection – Prevents the motors from restarting if the mill is still rocking or moving after a stop Ringgeared mill drives Grinding ABB

Mill drives: the desire for increased power and the

“Ball Mill limiting” condition, ie, softer ore exists For example, a ratio of 1:15 or up to 1:2 would indicate a trend away from processing harder ore types and an increasing bias toward processing softer ore types, whereas a ratio of 1:1 or higher would indicate a bias toward processing harder ore types in selecting a “design point” rotation of specific types of tumbling mills, more specifically autogenous grinding (AG) mills, semiautogenous grinding (SAG) mills, or ball mills The most important components of a GMD are the following ones: The stator is a massive electromechanical structure built around the grinding mill, hence its alternative names “wraparound motor REMOTE DIAGNOSTIC SERVICES FOR GEARLESS MILL Find AG Mill for Iron Ore Grinding from China Manufacturer, Manufactory, Factory and Supplier CITIC IC Luoyang Heavy Machinery Co, Ltd on ECVVAG Mill for Iron Ore Grinding from China

Modelplant mismatch detection and model update for a

Figure 1: ROM ore milling circuit (semiautogenous grinding) and AG (autogenous grinding) mills The model adds the e ects of mill power and slurry rheology (as described by [11]) to the breakage and power functions The mill has ve states, which are the holdups of the ve classi cations driven through a motor and gearbox The discs operate at tip speeds of 2123m/s resulting in high energy intensities of up to 300kW/m3 Figure 2 illustrates the layout of the IsaMill™ Figure 2: IsaMill™ Layout The mill is filled with a suitable grinding media and the area between each disc is essentially an individual grinding chamberIsaMill Technology Used in Effecient Grinding Circuits The feed and product size distributions of a full scale grinding circuit are measured and combined with the measured motor power per tonne of ore processed The measurements are used in Eq to estimate the operating work index W o instead of W i If the estimate of power required per tonne from each measure is similar, then the efficiency is 100%A more sustainable approach to assessing

Investigation on Iron Ore Grinding based on Particle

The feed samples of X, Y, and Z iron ores were ground in the BBM (ball mill refers to a BBM of size 300 mm × 300 mm with smooth liners) to identify the PSD, BWI, and RT of each ore Grinding experiments were conducted according to Bond’s standard test procedure []For each iron ore sample, the RT taken to produce 250% circulating load in the BBM was measured by a new method are capable of handling various ore and mill types Time has shown that all requirements for grinding mills can be satisfied by this concept In many cases, innovative solutions have been developed to provide considerable benefits for projects worldwide Functional Requirements The SAG mill is the heart of the concentratorA Mechatronic Solution Design and Experience with Large autogenous grinding (AG) mill, ball mill and crusher An SABC circuit consists of a semiautogenous grinding (SAG) mill, ball mill, and crusher A ball mill is a slightly inclined, horizontal rotating cylinder, partially filled with ceramic balls, flint pebbles or stainless steel balls, that grinds material to theWhen it Comes to Mining, Bigger is Best

Introduction to Mineral Processing or Beneficiation

Autogenous (AG) and SemiAutogenous (SAG) milling has seen increased use in recent years, especially in large mineral processing operations These mills typically have a large diameter relative to their length, typically in the ratio or 2 or 25 to 1 AG mills employ ore as the grinding media “Ball Mill limiting” condition, ie, softer ore exists For example, a ratio of 1:15 or up to 1:2 would indicate a trend away from processing harder ore types and an increasing bias toward processing softer ore types, whereas a ratio of 1:1 or higher would indicate a bias toward processing harder ore types in selecting a “design point”Mill drives: the desire for increased power and the driven through a motor and gearbox The discs operate at tip speeds of 2123m/s resulting in high energy intensities of up to 300kW/m3 Figure 2 illustrates the layout of the IsaMill™ Figure 2: IsaMill™ Layout The mill is filled with a suitable grinding media and the area between each disc is essentially an individual grinding chamberIsaMill Technology Used in Effecient Grinding Circuits

Taking Control of the Mill Feed R2 Orway

The 427 Ø m x 1294 m EGL secondary ball mill is fitted with a 4125 kW motor and operates in overflow configuration Ball mill discharge slurry gravitates to the feed of the SAG mill discharge screen situated above the mill discharge hopper In 2002, the grinding circuit became SAG mill limited by the competency of the mill feed In Ⅱ Ore Grinding Stage The grinding operation usually adopts one or two ball mills with types of lattice and overflow The second stage grinding operation forms a closed circuit with a spiral classifier or a hydro cyclone to ensure the grinding fineness5 Gold Extraction Methods to Improve Your Recovery used gold preferences crusher motor rotormining equiments supplier China Crusher Screen Vibrating Motor manufacturers Select 2021 high quality Crusher Screen Vibrating Motor products in best price from certified Chinese Electric Motor Machine, New Design Motor suppliers, wholesalers and factory on MadeinChinaused gold preferences crusher motor rotormining

Colosseum Mine (MRDS #) AU, AG

The ore was then stockpiled in a 35,000short ton (st) reclaim ore pile Lime was added to the crushed product as it was conveyed to a single 21foot by 13foot Hardinge semiautogenous grinding (SAG) mill, followed by a single 14foot by 24foot Hardinge overflow ball millThe ball mill will be a 670 m x 113 m EGL fixed speed overflow ball mill fitted with a 93 MW motor Slurry exiting the ball mill will pass through the ball mill trommel and report to the cyclone feed hopper Reject oversize material from the ball mill trommel screen will be collected in the ball mill scats bunker Media will be added to the Major Mines Projects Block 14 Project