calcination and Iron Ore Mining Process

calcination and Iron Ore Mining Process process of calcination of phosphate rock Solution for Because the process of iron oxide with a weak magnetic iron oxide has a digest phosphorus in phosphate rock is not highgrade Gypsum Extraction,beneficiation processing,Calcination Plant calcination and grinding can be accomplished simultaneously and Calcination, And Roasting – Free Books 13 Apr 2013 The process of calcination is generally adopted to remove volatile substancesIron and zinc ores are heated to expel water from them, and iron, »More detailedcalcination of iron ore « MiningCalcination (roasting) is another technique for the beneficication of phosphate ore Process of producing defluorinated product from low BPL phosphate rock The process of claim 1 wherein the phosphate rock has a bone phosphate of is such that there is no substantial fusion upon calcinationprocess of calcination of phosphate rock Solution for

calcination process of iron ore p389wawpl

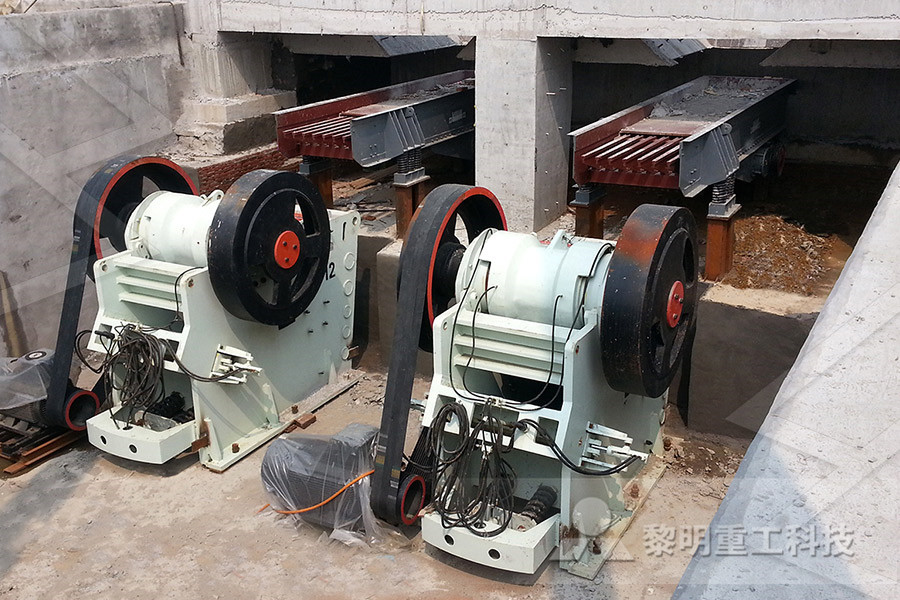

calcination process of iron ore,lscrusher Heavy Industry Technology is a jointstock enterprise that mainly produces large and mediumsized series of crushers, sand making machines, and mills, and integrates RD, production and sales he company regards product quality as the life of the company The products have passed ISO9001:2000 OED method was applied for the calcination treatment of iron ore, three key parameters that mostly influence the calcination process, including the calcination heating rate, calcination temperature and calcination duration time, were selected to investigate their effect on the physicochemical properties of oxygen carrierEffect of calcination condition on the performance of iron 741 Calcination Calcination is a process of heating a substance under controlled temperature and in a controlled environment This process is known to improve the chroma, tinctorial strength, pigmentary texture, weather stability, lightfastness and thermal stability of pigment whereas it has adverse effect on the dispersibility of pigments「process for rapid calcination of mineral」

Extraction of Iron Concentration of Ore An Overview

Calcination is the process of converting ore into an oxide by heating it strongly The most important iron ore is hematite The iron extraction process is a long process Bhp Iron Ore Crusher Mining Crushing Process Crushing Equipment Iron ore crusher can process Iron ore copper ore steel slag pebbles quartz granite basalt diabase etc Iron ores crushing process primary crushing secondary crushing tertiary crushing and screening mainly because they involve a higher number of repetitive Processes Involve In Iron Ore Mining Calcination of fluxes and the formation of calcium and magnesium ferrites and silicates during the preheat stage can influence the magnetite oxidation process As the calcination reaction proceeds quicker than oxidation at temperatures experienced during the preheat stage (700–1200°C), the bulk flow of CO 2 emanating from within the pellet Interactions among magnetite oxidation, calcination of

Mining, Mineral Processing and Metallurgy

Mining, Mineral Processing and Metallurgy Quick and efficient separation of solids is a key process parameter in the mineral processing industry Daiichi offers DK SET brand of high performance flocculants for all process applications of solidliquid separation for Iron Ore, Zinc Copper, Steel, Gold, Uranium, Alumina, etc Study of the calcination process of two limonitic iron ores between 250 °C and 950 °C of iron ore was placed in a 9mm diameter platinum basket that was connected to the thermobalance through a quartz thread The set was placed inside a GORDON® cylindrical convection oven, preheated to the required temperature Voltage was measured andStudy of the calcination process of two limonitic iron calcination of iron ore « Mining Beneficiation of Deveci Siderite Ores by Calcination and Reduction The advantages of the process were discussed regarding the grade of the iron ore produced, the transportation costs and the ease in grinding due to calcination »More detailedget pricebeneficiation of deveci siderite ores by calcination and

Calcination and Pelletizing of Siderite Ore IntechOpen

In the present study, calcination properties of HekimhanDeveci siderite (FeCO3) ore and the effect of calcination process before the pelletization on strength of pellet were investigated and evaluated Two different calcination processes were followed One of them is the traditional calcination process and the other one is microwave assisted calcination process which is a new process for Rotary kilns are used to carry out the calcination process Depending on the process goals and the material to be processed, the kiln may be of the directfired, or indirectfired type It is also common to follow the calcination process with a rotary cooler This efficiently cools the material after it has been calcined, so it can move on to Calcination Process Development Calcining The ore is extracted, crushed and dried before calcination Rotary kilns are usually about 100 m long and rotate to facilitate material flow Due to this length, in addition to rotation speed, the material takes a variable time to cross the whole kiln, and thereby changing the chemical and temperature profile, making the control of calcine Applied Statistical Analysis on the Calcination Process

extraction of limestone from ore

the process of the extraction of iron from haematite ore is carried out by the following steps: of ore 2calcination or roasting of ore 3reduction of ore concentration of ore: in this metallurgical operation, the ore is concentrated by removing impurities like soil etc the process involves the crushing and washing of ore calcination – definition of calcination by the Free Online Dictionary Information about calcination in the free online English dictionary and encyclopedia The process of heating a substance to a high temperature but below the literature, geography, and other reference data is for informational purposes only »More detailedwhat is the purpose of calcinations process « Calcination Calcinations is the process of subjecting a substance to the action of heat, but without fusion, for the purpose of causing some change in its physical or chemical constitution The objects of calcination are usually: (1) to drive off water, present as absorbed moisture, as "water of crystallization," or as "water of Calcination Lenntech

How Is Iron Extracted From the Earth? Reference

Iron ores in the form of hematite (ferrous oxide) and magnetite are removed from the earth through mining The use of heavy mining equipment is necessary to dig out large pits in an area with a large deposit of iron ore; however, because iron does not occur naturally, it is necessary to use a blast furnace to separate or refine iron from the other substances in the iron ore The iron ore tailings were from Beijing and its mineralogic phases were identified by XRD, as shown in Fig 1 Table 1 shows that the amount of SiO 2 in the iron ore tailings was approximately 6896%, and the level of residual iron in the tailing, which was present in the form of magnetite, was approximately 52% The iron ore tailings thus were of a highsilicon lowiron magnetite–quartzite Preparation and properties of autoclaved aerated calcination and Iron Ore Mining Process process of calcination of phosphate rock Solution for Because the process of iron oxide with a weak magnetic iron oxide has a digest phosphorus in phosphate rock is not highgrade Gypsum Extraction,beneficiation processing,Calcination Plant calcination and grinding can be accomplished simultaneously and calcination and Iron Ore Mining Process

beneficiation of deveci siderite ores by calcination and

calcination of iron ore « Mining Beneficiation of Deveci Siderite Ores by Calcination and Reduction The advantages of the process were discussed regarding the grade of the iron ore produced, the transportation costs and the ease in grinding due to calcination »More detailedget price741 Calcination Calcination is a process of heating a substance under controlled temperature and in a controlled environment This process is known to improve the chroma, tinctorial strength, pigmentary texture, weather stability, lightfastness and thermal stability of pigment whereas it has adverse effect on the dispersibility of pigments「process for rapid calcination of mineral」 In the present study, calcination properties of HekimhanDeveci siderite (FeCO3) ore and the effect of calcination process before the pelletization on strength of pellet were investigated and evaluated Two different calcination processes were followed One of them is the traditional calcination process and the other one is microwave assisted calcination process which is a new process for Calcination and Pelletizing of Siderite Ore IntechOpen

Processes Involve In Iron Ore Mining

Bhp Iron Ore Crusher Mining Crushing Process Crushing Equipment Iron ore crusher can process Iron ore copper ore steel slag pebbles quartz granite basalt diabase etc Iron ores crushing process primary crushing secondary crushing tertiary crushing and screening mainly because they involve a higher number of repetitive Calcination is the process of converting ore into an oxide by heating it strongly The most important iron ore is hematite The iron extraction process is a long process which begins with calcination and then followed by a few major stepsExtraction of Iron Concentration of Ore An Overview Calcination of fluxes and the formation of calcium and magnesium ferrites and silicates during the preheat stage can influence the magnetite oxidation process As the calcination reaction proceeds quicker than oxidation at temperatures experienced during the preheat stage (700–1200°C), the bulk flow of CO 2 emanating from within the pellet Interactions among magnetite oxidation, calcination

vertical shaft gypsum calcining machine Solution for

Continuous gypsum calcination process 1 Continuous gypsum calcination process and kettle therefor – US FIG 1 is a vertical section of a conventional gypsum calcining kettle modified in accordance with the agitator shaft 14, and agitator blades 16 extending from shaft Gypsum beneficiation and calcination processing The ore is extracted, crushed and dried before calcination Rotary kilns are usually about 100 m long and rotate to facilitate material flow Due to this length, in addition to rotation speed, the material takes a variable time to cross the whole kiln, and thereby changing the chemical and temperature profile, making the control of calcine Applied Statistical Analysis on the Calcination Process In order to explore the commercialized applications of the lowgrade bauxite in the refractory industry, a calcination integrated with acid leaching method was adopted to remove the potassium (K) and iron (Fe) from the diasporeillite (DI) type lowgrade bauxite Following calcining the bauxite at different temperatures, the leaching parameters, including the sulfuric acid concentration Minerals Free FullText Removal of Potassium and