Ore Beneficiation an overview ScienceDirect Topics

Iron ore beneficiation can be brought about through three approaches, namely, selective dissolution, microbially induced flotation, and selective flocculation–dispersion The bioprocesses are specially suited to treat fines, slimes, and waste tailings 4 Potential applications include i Dephosphorization ii Desulfurization iii Desiliconization iv Iron ore beneficiation technology and process 121720; 349 Views; icon 0 Iron ore is one of the important raw materials for the production of pig iron and steel in the iron and steel industry There are many types of iron ore According to the magnetic properties of the ore, it is mainly divided into strong magnetism and weak magnetismIron ore beneficiation technology and process,gravity and Experimental study on the beneficiation of lowgrade iron ore fines using hydrocyclone desliming, reduction roasting and magnetic separation Beneficiation of 2 mm lowgrade iron ore tailings (507% Fe, 108% SiO2 and 44% Al2O3) from Western Australia was studiedIron Ore Beneficiation Research Papers Academiaedu

Effective Separation and Beneficiation of Iron and

Through the reduction roasting–magnetic separation process, most of the iron is beneficiated in the concentrate, and nonmagnetic minerals such as FeS and CrS remain in the tailings Consequently, the separation and beneficiation of iron and chromium occur Iron ore beneficiation is an industry with large investment and high return Iron ore beneficiation methods include magnetic separation process, flotation process, gravity separation process, electric separation process, wind separation process, etc Different methods are used for different iron raw ore with different propertiesIron Ore Beneficiation Test Explaine Mining Pedia Iron ore beneficiation plant The iron occur in Femineral ores contains impurities of Phosphorus, sulphur and high alkali as well as impregnations of waste rock To produce a metallurgy treatable concentrate the ore has to be grind for mineral liberation, enriched for concentration and dewatered for transportationIron ore beneficiation plant, iron ore crushing and

Beneficiation of Iron Ores – IspatGuru

These techniques are used in various combinations for the beneficiation of iron ores For beneficiation of a particular iron ore the emphasis is usually to develop a cost effective flow sheet incorporating necessary crushing, grinding, screening and beneficiating techniques which are necessary for the upgrading of the iron ore A typical flow sheet for iron Abstract In this paper, a sample from Tangezagh iron mine was characterized by gravity and magnetic separation methods The mineralogical studies showed that hematite and goethite are the main ironbearing minerals with insignificant amounts of FeO The results indicated that spiral separation yields higher separation efficiency than othersA Beneficiation Study on a Low Grade Iron Ore by Gravity beneficiation plants for upgrading iron ore and pelletizing plants for agglomerating Kobe Steel has much experience in constructing both beneficiation and pelletizing plants and has its own pelletizing process (KOBELCO pelletizing system) This paper contains general information on beneficiation and pelletizing plants,Beneficiation Plants and Pelletizing Plants for Utilizing

Basic Beneficiation Flowsheet For Iron Ore List

Beneficiation Of Iron Ore Slimes Beneficiation of alumina rich iron ore slimes is a major challenge for the Indian iron ore industry High alumina is deleterious for the performance of both blast furnace as well as sintering plants Slimes generally contain 5 Iron ore beneficiation technology and process 121720; 349 Views; icon 0 Iron ore is one of the important raw materials for the production of pig iron and steel in the iron and steel industry There are many types of iron ore According to the magnetic properties of the ore, it is mainly divided into strong magnetism and weak magnetismIron ore beneficiation technology and process,gravity Hematite beneficiation technology 083120; 443 Views; icon 1; Hematite beneficiation technology With the rapid economic development, the iron ore resources of the concentrator are decreasing year by year, and the degree of "lean, fine and heterogeneous" of selected ore is obviously increasing, the supply conditions are becoming more and more demanding, the difficulty of sorting is Hematite beneficiation technology,processing of iron

Iron Ore Beneficiation Research Papers Academiaedu

Beneficiation of 2 mm lowgrade iron ore tailings (507% Fe, 108% SiO2 and 44% Al2O3) from Western Australia was studied The sample consisted of hydrohematite, goethite and Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron magnetite) Ores are normally associated with unwanted gangue material Grade of iron ore is usually determined by the total Beneficiation of Iron Ores – IspatGuruBeneficiation of hematite iron oreFirst Latest special jigging PLANT for HAMATITE IRON ORE in india Emf tech jig is a simple mineral processing device using water and the force of gravity to separate a raw ore stream by densityIron Ore Beneficiation Plant at Best Price in India

Recovery of Iron Bearing Minerals from Beneficiation

To identify and establish beneficiation techniques for slime, a comprehensive research work was carried out on beneficiation plant 2 thickener underflow (Tailing) Iron ore slimes (45 micron ~800%) generated at beneficiation plant 2 assaying 467% Fe, 1082% SiO2, and 458% Al2O3 have been subjected to various beneficiation studies like cyclone, wet high intensity magnetic separator and In this paper, a sample from Tangezagh iron mine was characterized by gravity and magnetic separation methods The mineralogical studies showed that hematite and goethite are the main ironbearing minerals with insignificant amounts of FeO The results indicated that spiral separation yields higher separation efficiency than others The combination of spiral and multi gravity methods showed A Beneficiation Study on a Low Grade Iron Ore by beneficiation plants for upgrading iron ore and pelletizing plants for agglomerating Kobe Steel has much experience in constructing both beneficiation and pelletizing plants and has its own pelletizing process (KOBELCO pelletizing system) This paper contains general information on beneficiation and pelletizing plants,Beneficiation Plants and Pelletizing Plants for Utilizing

IMBS The New Age of Iron

Iron Mineral Beneficiation Services (IMBS) is a South African company focused on the production of metallic iron units IMBS subscribes to the Triple Bottom Line (3BL) philosophy which states that to be successful a company needs to take into account the community it operates in, its impact on the environment as well as its economic prosperity • The Beneficiation Plant has been designed to process up to 21 Mtpa of titanomagnetite ore and produce up to 07 Mtpa of magnetite concentrate • The magnetite concentrate produced by the Beneficiation Plant is planned to be transported to the DPF for processing into vanadium pentoxide, titanium pigment and iron oxide fines for global exportUPDATE ON MOUNT PEAKE FRONTEND ENGINEERING Iron ore beneficiation technology and process 121720; 349 Views; icon 0 Iron ore is one of the important raw materials for the production of pig iron and steel in the iron and steel industry There are many types of iron ore According to the magnetic properties of the ore, it is mainly divided into strong magnetism and weak magnetismIron ore beneficiation technology and process,gravity

Hematite beneficiation technology,processing of iron

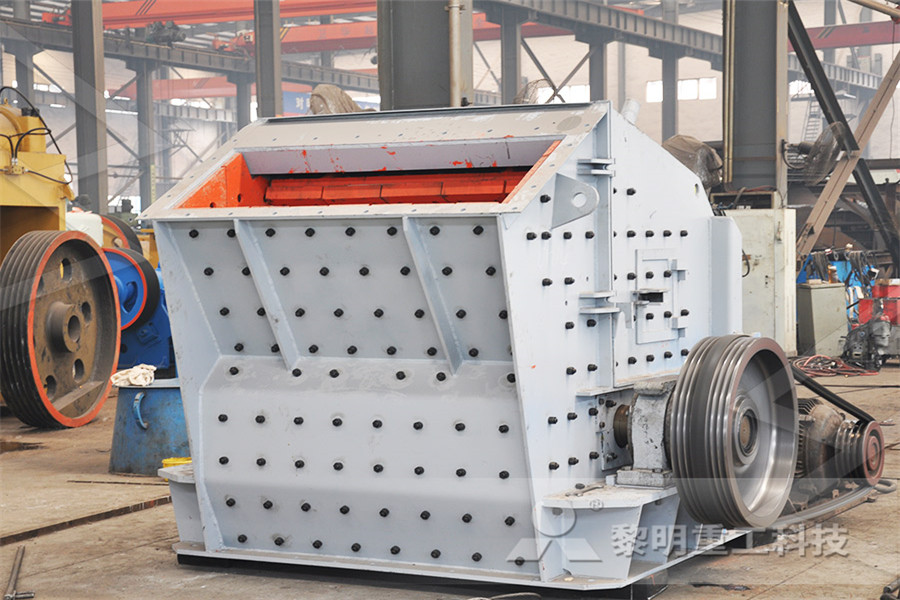

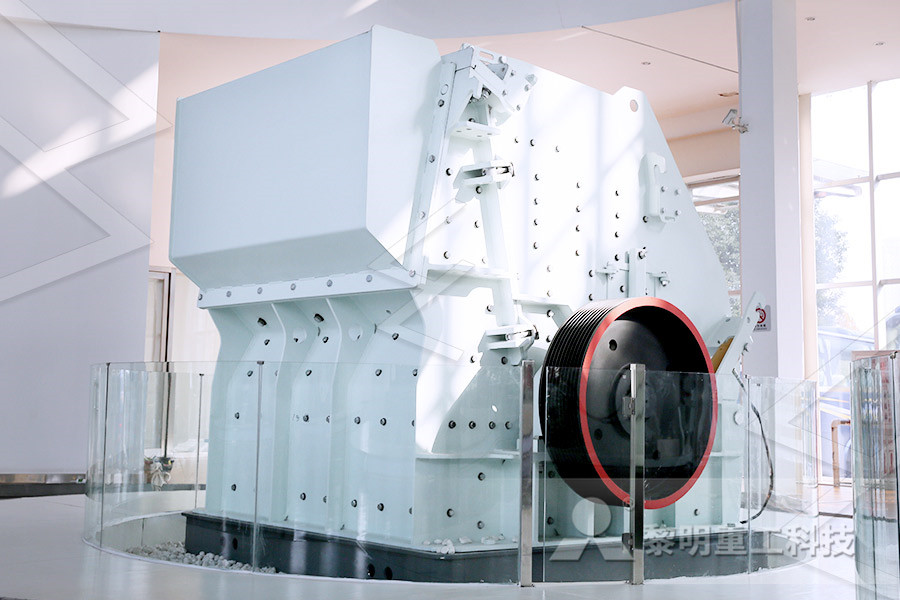

Hematite beneficiation technology 083120; 443 Views; icon 1; Hematite beneficiation technology With the rapid economic development, the iron ore resources of the concentrator are decreasing year by year, and the degree of "lean, fine and heterogeneous" of selected ore is obviously increasing, the supply conditions are becoming more and more demanding, the difficulty of sorting is iron ore beneficiation explained There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectivelyIntroducing advanced technology and craftsmanship, adopting iron ore beneficiation explained Sourena 10 Most Popular Iron Ore Beneficiation Machines Last Updated : January 02,2020 Steel is an essential material used in our modern life and also the cornerstone of industrial development and plays an important role in economic growth The main material required in steel making process is iron ore According to the incomplete statistics, 98% of 10 Most Popular Iron Ore Beneficiation Machines

Iron Ore Beneficiation Plant Manufacturer,Exporter

Product Description With the collaboration and ample support of our experienced professionals, we have been instrumental in manufacturing, supplying and exporting highly functional Iron Ore Beneficiation Plant Widely applicable in chemical, mining, food, metallurgy and industries; this industrial plant is set up can eliminate assorted contaminant particles of silica as well as aluminum from Iron ore is a mineral aggregate that contains iron elements or iron compounds that can be used economically It is the earliest discovered, most widely used, and most used metal in the world Its consumption accounts for about 95% of the total metal consumption Iron ore is an important raw material for iron and steel production enterprisesIron Ore Beneficiation Plant in Vietnam Beneficiation of Lowgrade Iron Ores: 2 IPR Status Patent/Abroad IPR Details3 Application/Uses 4 Salient Technical Features including Competing Features: The technology is based on processing of lowgrade iron ores primarily involving washing, gravity and magnetic separationBeneficiation of Lowgrade Iron Ores CSIRNML

Beneficiation Equipment Iron Ore Washing and

KINC’s IOBP plant for iron ore beneficiation is milestone in a journey of excellence Capable to execute beneficiation plant on EPC, concept to commissioning basis with vast experience of working on various ores KINC with inhouse facility to design, manufacture main equipment required for washing circuits, floatation, screening circuits and Worldwide Industrial Information Commodities: Iron Ore Area: Odisha Type: Iron Beneficiation Plant Products: Concentrated Iron OreEssar Steel Dabuna Iron Beneficiation PlantIron Ore Beneficiation Plant has been producing high grade iron ore concentrate as its main product The high grade iron ore concentrate is key raw material input for the steel making process M/s Pacific Iron Manufacturing Limited is spread over in the area of 125 acres currently in the Village Parakheda, Tehsil Sihora of Jabalpur District Pacific Iron Manufacturing Ltd Manufacturer from