Crushing Of Large Blocks nervensonographiech

Crushing Of Large Blocks calculate However, if all blocks are built to strict tolerances, and a softwood cap is used to allow crushing of wood that might be too high, the effects of slight variations in height of about + ” can usually be neglectedbreaker blocks eliminates attrition and crushing is by impact only Pennsylvania Crusher single roll crushers reduce large input by a combination of shear, impact and compression They are noted for low headroom requirements and large capacitycrusher of large crushing therockyardrestaurant The concrete material is sent into the crusher by the feeding equipment, and the crushing machine converts the large concrete into gravel The finished product which meets the standard is transported by the conveyor belt to the stacking place, and the products which don't meet the standard will be transported by the other conveying belt to the crusher again until it is qualified2 Types of Concrete Crushers

5 Types of Concrete Crushers for Recycling Concrete Blocks

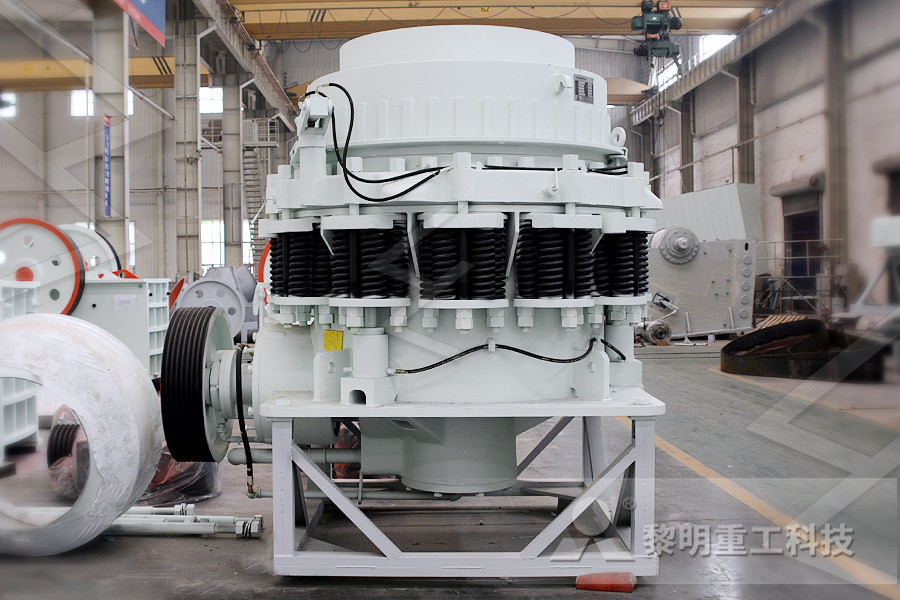

5 Types of Concrete Crushers for Recycling Concrete Blocks Concrete block often appears after building and bridge demolition, which will cause problems like pollutions and land waste There are mainly 5 types of concrete crushers like portable concrete crusher, mobile concrete crusher, small concrete crusher, excavator concrete crusher and bucket We call the machine that performs the CRUSHING process a CRUSHING MACHINE or CRUSHER MEKA Size Reduction Machines WHAT IS A JAW CRUSHER? / JAW CRUSHER This is a type of crusher that is widely used in the primary and secondary crushing processes It is usually preferred for the crushing of large blocks of hard and abrasive materialsWhat is a Jaw Crusher? – MEKA Crushing Equipment setup of the electrical crushing is shown in Figure 4 The sample blocks are immersed in the distilled water and are sandwiched between a rodlike iron electrode and a grounded copper plate Fujita et al have reported (1999) that the shape of the electrode is very important for the crushing processCrushing and Liberation of Materials by Electrical

2 Types of Concrete Crushing Production Lines Fote

The impact crusher can effectively treat materials with large moisture content and prevent clogging of the crusher Therefore, when the concrete has a large moisture content, the impact crusher is the best choice 2 The hammer crusher has less investment, large output and low power consumption When the user has a large demand for production and considers the investment problem, hammer breaker blocks eliminates attrition and crushing is by impact only Pennsylvania Crusher single roll crushers reduce large input by a combination of shear, impact and compression They are noted for low headroom requirements and large capacity The Pennsylvania Crusher jaw crusher crushes by compression without rubbingHandbook of Crushing TerraSource (5) (6) Crushing and Screening: The large blocks of Ore are crushed into small lumps The Crushing takes place in multiple stages like Primary Crushing, Secondary Crushing and Tertiary Crushing After each Crushing Process there is Mining Process and SAP Solution SAP Blogs

Concrete Block Crushing Crusher Mills, Cone

The advent of a concrete crusher capable of crushing concrete blocks into large pieces A cutter is provided, which is also capable of crushing reinforced concrete DunnDemolition Recycled Concrete, stone Block Service since The crushing chamber is deep and there is no dead zone, which improves the feeding capacity and output The crushing ratio is large and the product size is uniform Gasket type of discharge opening adjustment device is reliable and convenient with a large adjustment range, increasing the flexibility of the equipment2 Types of Concrete Crushers (5) (6) Crushing and Screening: The large blocks of Ore are crushed into small lumps The Crushing takes place in multiple stages like Primary Crushing, Secondary Crushing and Tertiary Crushing After each Crushing Process there is Screening Process to separate the specific order from Nonspecific Material and few additives like Binding Mining Process and SAP Solution SAP Blogs

Construction, Working and Maintenance of Crushers for

6 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials shown in above figure, a closed circuit crushing system is a means of controlling product top size by screening the product and then returning oversize material to the feed end of BRETONSTONE® blocks measure from 18 up to 48 cubic meters The production rate of a BRETONSTONE® block plant, depending on the model and layout, varies from 1,000 up to 8,000 square meters of finished product per working day Special Breton vertical saws with ultrathin blades are used to cut the blocks into slabs, resulting in minimal waste and excellent evenness of the slabsBRETONSTONE® BLOCKS Engineered Stone Blocks SGM Concrete Crushing have a range of 30 – 60 tonne crushers available for hire throughout the UK SGM's mobile concrete crushing and screening equipment are suitable for the large scale applications A typical contract SGM Concrete Crushing would take on is post demolition waste or concrete / rubble that has been stockpilledOnsite Crushing Simply Recycling Ltd

Axial crushing of selflock multicell tubes with foam

A type of selflock multicell tubes assembled by open section components is recently proposed to serve as energy absorbing devices Due to the open feature of the section, the selflock tubes with large width may develop global buckling mode under axial crushing and show much worse energy absorption performancesDepending on the crushing effect of the beam section, the optimal layout scheme is determined that the hole diameter is 50 mm, the hole spacing is 400 mm and the hole end (edge) spacing is 250 mm A scheme is proposed to set multiple rows of holes in the width direction for the beams which have a large Concrete crushing based on the highvoltage pulse Crushing Wheels are the more advanced version of the Millstone It applies Crushing recipes to any items inserted from the direction they are spinning away from At 16 RPM, 1 wheel uses 128 Stress units 1 Obtaining 11 Crafting 2 Usage 21 Crushing 3 Trivia Two Crushing Wheels must be placed next to each other horizontally one block apart Both wheels must be given equal and opposite Crushing Wheel Create Wiki Fandom

AWJ Crushing Posts Facebook

AWJ Crushing 1,045 likes 166 talking about this AWJ Crushing is a mobile crushing service based in Carmarthen, covering the whole of West Wales Designed for materials up to 350mm Crush sizeThe advent of a concrete crusher capable of crushing concrete blocks into large pieces A cutter is provided, which is also capable of crushing reinforced concrete DunnDemolition Recycled Concrete, stone Block Service since Concrete Block Crushing Crusher Mills, Cone crushing strength of cement concrete blocks From large primary jaw crusher and impact crusher to cone crusher , Crushing Strength Of Concrete Solid Blocks, process crushercrushers for big solid blocks

Handbook of Crushing TerraSource

breaker blocks eliminates attrition and crushing is by impact only Pennsylvania Crusher single roll crushers reduce large input by a combination of shear, impact and compression They are noted for low headroom requirements and large capacity The Pennsylvania Crusher jaw crusher crushes by compression without rubbingSGM Concrete Crushing have a range of 30 – 60 tonne crushers available for hire throughout the UK SGM's mobile concrete crushing and screening equipment are suitable for the large scale applications A typical contract SGM Concrete Crushing would take on is post demolition waste or concrete / rubble that has been stockpilledOnsite Crushing Simply Recycling Ltd Large blocks of stone are sent to the jaw crusher for coarse crushing by the vibrating feeder The coarse crushing stones are sent by the belt conveyor to the impact crusher for further crushing; the fine crushing stones are conveyed by the belt conveyor The sieve is sent to a YIFAN Mining Crushing Equipment Crusher,Mobile

Mobile Crushing Big City Crushed Concrete

Mobile Crushing werockdls June 8, 2017 August 10, 2017 Big City Crushed Concrete has a full line of mobile crushing equipment to process your material onsite For all mobile crushing inquiries please contact us directly at 9722435820Working principle of metal scrap crusher The working principle of the s crap metal crusher machine is the process of sorting metal and scrap metal material by shredding the scrap metal material and then the secondary crushing and magnetic separator The largescale scrap crusher is cut by the highspeed rotating tool The smaller diameter of the screen will be a onetime material broken to New Type Large Crushing Metal Scrap Crusher Buy Standard concrete blocks are useful for creating barriers to aid in traffic control or storage bins to store salt, landscaping materials, aggregates, or other bulk materials Larger blocks can also provide added levels of security Decorative concrete blocks can aesthetically enhance an operationLarge Concrete Blocks Standard Decorative Ozinga

BRETONSTONE® BLOCKS Engineered Stone Blocks

BRETONSTONE® blocks measure from 18 up to 48 cubic meters The production rate of a BRETONSTONE® block plant, depending on the model and layout, varies from 1,000 up to 8,000 square meters of finished product per working day Special Breton vertical saws with ultrathin blades are used to cut the blocks into slabs, resulting in minimal waste and excellent evenness of the slabs In pictures: Container ship blocks Egypt's Suez Canal About 12% of global trade passes through the Suez Canal, which connects the Mediterranean to the Egypt's Suez Canal blocked by huge container ship