Gold Metallurgy and Leaching Process

Leaching, often gold, is the process of extracting a soluble constituent from a solid by means of a solvent In extractive metallurgy, of gold, it is the process of dissolving a certain mineral (or minerals) from an ore or a concentrate, or dissolving certain constituents from materials such as a calcines, mattes, scrap alloys, anodic slimes, etc, to achieve either one or two purposes: lurgical gold extraction routes utilize a leaching step to produce a goldbearing solution as an intermediate product while the recycling of secondary gold from electronic and precious metal scrap is based on the selective and fast dissolution of the precious metal Therefore, A Method for Leaching or Dissolving Gold from Ores or PreciousA Method for Leaching or Dissolving Gold from Ores or Heap leaching can be considered as a percolation process on ore piles The process is characterized for its economic cost against the agitated leaching process when the ore deposit has a low gold content Typically the process can process ores whose gold content is 0811 g/tGold Extraction Recovery Processes 911 Metallurgist

Processing Gold Ores Using Heap LeachCarbon

in gold ores may range from less than 1 ppm to several hundred times the level of the gold present in an ore Generally, silver is also dissolved by the cyanide solution and follows the gold through the process sequence Iron sul fide minerals, which are common constituents of gold ores, are oxidized to effects Diagnostic leaching was used to show that mineralogy was not an important factor in the enhanced gold extraction in the presence of activated carbon for the ores Kinetic models were developed for the leaching of gold from the ore, adsorption onto activated carbon and pregrobbing at the ore surface A variable order empiricalThe leaching and adsorption behaviour of gold ores The mineralogy of gold ore deposits ranges from freemilling, metal oxide ores, to sulphides The sulphide ores tend to be refractory to leaching when employing a normal cyanidation process Recoveries of gold, when employing a normal cyanidation process in the treatment of sulphide ores, tend to be less than 80%Improving the gold leaching process of refractory ores

What Are The Factors Affecting Gold Leaching?

Gold is not active metals, in the process of cyanide leaching, gold can be under the action of oxygen and cyanide complexation reaction (CN), produce a watersoluble melamine aurous acid salt complex [Au (CN) 2], so the cyanide agent is a key factor determine gold dissolved, in general, to ensure that a certain amount of free cyanide in the To reach the acceptable gold recoveries ie, +80%, some ores are leached for 24 h, or more, depending on the type of ore Faster kinetics would help in lowering the processing cost This work examines the development and application of the Jetleach reactor, as a device for improving the leaching kinetics of gold Improving the gold leaching process of refractory ores Bioreactors are able to process less gold ore at one time, but create a much faster oxidation process This process usually utilizes higher grade ores compared to heap leaching This type of bioleaching is characterized by a reactor tank in which relatively finely ground ore and nutrients are added, as well as bacteria containing solution to Bioleaching of Gold Ore Example Graduateway

Extraction of gold using cyanide NZQA

This process of dissolving the gold using cyanide is known as leaching Sometimes some other precious metals can also be leached along wit h the gold, for example silver This process of leaching is done in leaching tanks or by heap leaching where sodium cyanide is dripped onto a heap of gold ore and left to percolate its way through the heap of ren in gold leaching, is refortified with the lixiviant chemicals and pumped to the top of the heap Heap leaching is often broken into two principle distinctions, runofmine or ROM dump leaching and crushed ore heap leaching Dump leaching consists of truck enddumping of ore broken only by the drilling and blasting of mining activ ityDump and Heap Leaching HydroJexAn economically efficient leaching process relies on three fundamental disciplines geology, metallurgy and hydrodynamics The tools 2, Codelco Division Norte, Chile, Chuquicamata, Heap leach, Troubleshooting optimization 3, Arizona 7, Lassen Gold Mining, California, Hayden Hill mine, Heap leach, Closure Get a quotegold heap leaching process in chile

gold heap leaching agent Prominer (Shanghai)

Analysis of Factors Affecting Heap Leaching Process of Gold Ore Sep 1 2017 Heap leaching process is to heap up the gold ores that have been The dissolution rate of gold is tive and effective in terms of mining precious metals In concerning with this depletion of gold ore deposits in Kazakhstan, the extraction of gold from the tail Gold leaching experiments For comparison, the following leaching variants were carried out: Variant No 1 agitation leaching A STUDY OF THE BIOHYDROMETALLURGICAL METHOD posit and the residues of vacuumthermal processing of goldcontaining antimony ore deposit of Zopkhito, mountainous Racha (Georgia) Optimum conditions for leaching gold and silver from fine quartzite (Au 138 g/t, Ag 57 g/t) with the solutions of thiourea (CS(NH 2) 2 – 05%, H 2 SO 4 –04%, Fe 2 (SO 4) 3 03%) were established Methods of Processing of the GoldContaining Refractory

Process Instrumentation and Analytics Mining Brochure

tive maintenance 9 Level Flow Process protection Weighing Identification Flotation cells Concentrate Residual water and tailings Sump Filter Thickener and dewatering Additive tanks Leaching pad Ore additive silos Leaching agent Ore preparation Leaching agent tanks Insitu leaching: the process Level Pressure Flow Temperature Valve dation and poor gold cementation using MerrilCrowe process, with no deaeration Around 1980, two other solitary unsuccessful trials took place without continuity, perhaps due to the same intrinsic main causes, ie, high refractoriness of the ore and very random gold content One of those trials processed all the stocked ore by milling it Leaching of a Gold Bearing Partially Roasted Sulphide In many instances, however, their use is precluded by capital and operating cost rela tive to the value of the ore 386 N IGLESIAS AND F CARRANZA CONCENTRATE ~Preeonditioning I v ~ox PRESSURE I ~ o~ IDATIVE LEACHING[ ~ steam I F v l S/L I separation~ i v Lime Neutralization I v L E CY IOATION f NaCN I v Gold Recovery o [Waste dieposal] Fig 3Refractory goldbearing ores: a review of treatment

Mineral Processing DECHEMA

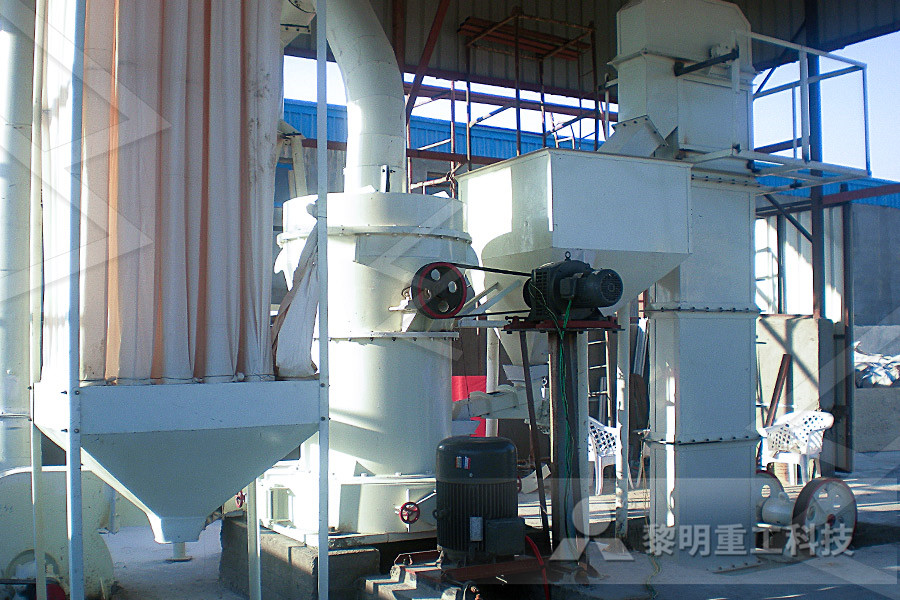

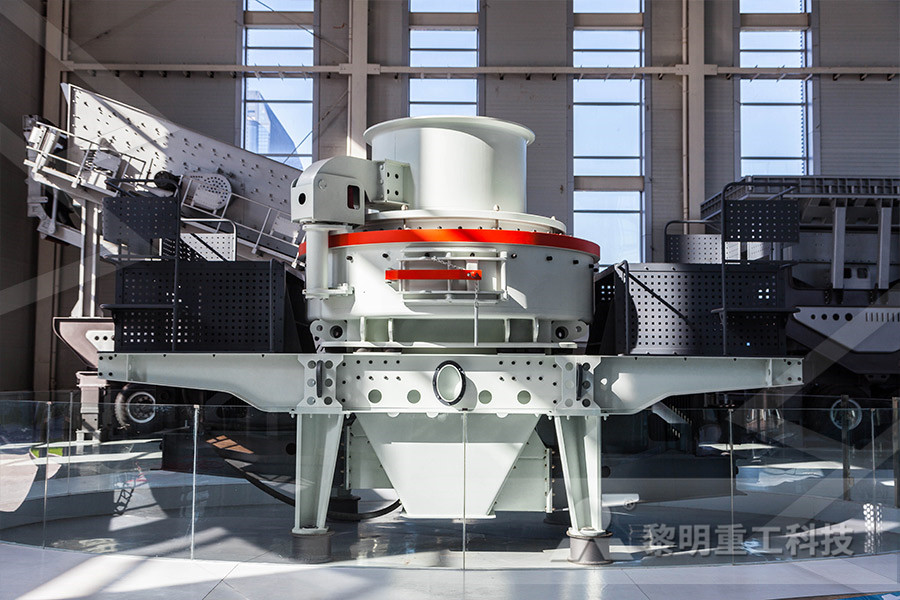

tive method for metal extraction, bioprocess engineering also becomes part of the equation In the idealized view, mineral processing for bioleaching is divided into the following steps: » Ore blending » Crushing / Grinding » Heap storage with defined permeability (heap leaching) » Leaching through microorganismore interactionThe first stage of the treatment process is the size reduction of the ore particles down to a size the gold minerals before they report to cyclone overflow Read more yanacocha gold single stage sag mill design, operation Cyclone Process In Gold Mining Gold leaching is a chemically controlled process in which temperature mostly affects the reaction rate The most interesting results shown in Fig 1 that after 264 h of leaching at room temperature, gold dissolution rate increased dramatically once the temperature has been raised to 60 CThe leaching and adsorption of gold using low

BIOLEACHING METAL SOLUBILIZATION BY

Tank leaching is practised for the treatment of refractory gold ores or in situ leaching proc tive metallurgy and biohydrometallurgy is now esses They are distantly related mucroorganisms typical acidophiles responsible for the leaching process, which makes them good candidates for future studies on metal bioleaching tive wireless networks for use in mine operations The WPN is designed to provide a secure, highbandwidth, reliable, and scalable way to access fixed and mobile applications, such as backhaul or bridging to process data, personnel or asset tracking, process and security video,, and voice communication Typically, a wireless plantMinerals Processing:Minerals Processing Because leaching processes include interactions between solid (ore) and liquid (sulfuric acid) phases such improvements may be achieved by the use of wetting agents This has already been proofed in the field of alkaline gold leaching BASF SE developed so far a tailormade wetting agent for gold leachingImprovements in Copper heap leaching by use of wetting

Processing technologies for goldtelluride ores

Gold telluride ores are important gold refractory ores due to the presence of sulfides and other gangue materials The classification and main physical properties of gold telluride ores were described, and possible treatment methods including flotation, leaching, and oxidation were reviewed The results show that flotation procedures are much easier for gold tellurides compared to other The first stage of the treatment process is the size reduction of the ore particles down to a size the gold minerals before they report to cyclone overflow Read more yanacocha gold single stage sag mill design, operation Cyclone Process In Gold Mining An ore may be treated experimentally with cyanide solution and 90 per cent, of the gold or silver dissolved This may be quoted as an extraction of 90 per cent, but it is preferable not to do so, since it is, at best, only an experimental extraction; and by no parallel method of operation in practice could such an “extraction” be actually realized as a recoveryGold and Silver Metallurgy Technology

What Does A Cyclone Do In The Gold Mining Process

Nov 24, 2010 Haber Gold Process leaching – 2000s research in New Jersey Visman Compound Water Cyclone (CWC) – 1970s research in Yukon Later chlorination found favour in large gold mining operations in However the patented process is complex and it does not seem to have become commercialised Read more O D Ogundare et al 303 In Figure 1(a), which shows the gold ore, about eighteen (18) peaks starting from 2= 15˚ to 2θ θ = 100˚ were observed while the extracted gold shown in Figure 1(b) revealed about five (5) peaks starting from 2θ = 45˚ to 2θ = 100˚ The SEM (Plate 1(a) and Plate 1(c)) shows that the morphology of the particles of gold ore from ItagunmodiBeneficiation and Characterization of Gold from Subsequently, the DIRB treated ore was subjected to chemical Microbial mineral processing technology is a simple and effec leaching by H SO showing encouraging outcome of nickel recov tive technology for extraction of metal values from lean grade ores 2 4 ery So, pretreatment of laterites by DIRB brought about higher and mineralAdvances in microbial leaching processes for nickel