Raw Material Handling and Storage Precast

Finally, since aggregate handling tends to increase the possibility of undesirable segregation, design your plant layout and equipment to keep handling operations to a minimum Cement The majority of precast concrete plants today employ bulk cement in their operations Bulk cement is stored in circular or square silos made of concrete or steelCement plant laboratories check each step in the manufacture of portland cement by frequent chemical and physical tests The labs also analyze and test the finished product to ensure that it complies with all industry specifications The most common way to manufacture portland cement is through a dry method The first step is to quarry the How Cement Is MadeB asic portland cement is alkaline in nature, so wet C austic concrete and other cement mixtures are strongly basic (pH of 12 to 13) Strong baseslike strong acidsare harmful, or caustic to skin D rying portland cement is hygroscopicit absorbs water In fact, portland cement needs water to hardenWorking Safely With Concrete Cement

Don't Be Rash: Handle Portland Cement Safely LHSFNA

Don’t Be Rash: Handle Portland Cement Safely Many Laborers work with portland cement by pouring it into forms, applying it through the process of shotcrete, screeding it and finishing it Workers who handle wet portland cement should know it can be dangerous due to the: Abrasive nature of concrete and cement JEFFERSONVILLE, Ind (AP) — A southern Indiana port on the Ohio River is preparing to handle barges loaded with parts as heavy as 100 tons (91 metric tons) for a cement plantIndiana port readies to handle big cargo for cement And depending on how that cement is produced, this can increase the material’s environmental impact This is in part because when calcium carbonate is fired in a kiln to produce conventional cement, a chemical reaction occurs that produces carbon dioxide (CO 2) Another source of cement’s CO 2 emissions come from heating cement kilns This Explained: Cement vs concrete — their differences,

Stacker and reclaimer systems for cement plants

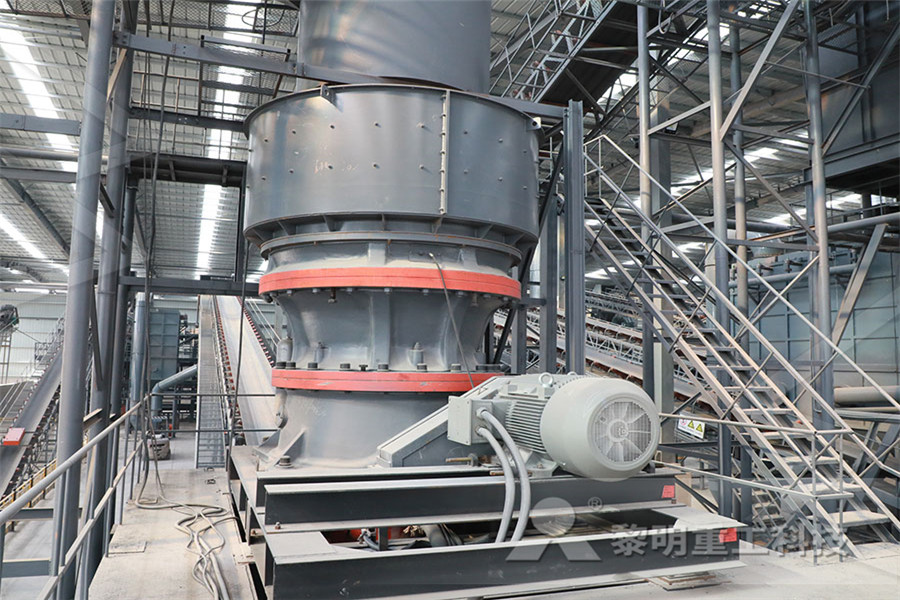

cement industry, matching kiln throughputs of up to 12,00013,000 tpd We offer an extensive selection of stacker and reclaimer systems to meet precisely your needs Selection criteria When planning which stacker and reclaimer system to use, you will need to consider various questions before selecting type and size: Homogenising effect required2 天前 Use concrete planters, with good drainage, for any kind of plant If the planter is solid, with no drainage, create an attractive display with a series of smaller pots set down into it Concrete planters work well in wet spots according to United States Department of Agriculture, “Working With Wet SpotsWhat to Plant in Concrete Planters eHowModern cement is a complex blend of finely ground minerals, and goes by the generic name of "portland" Concrete is made by combining the three ingredients in a mixer, whether that mixer is stationary or driving down the road, and the water is absorbed by the cementHow Cement Mixers Work HowStuffWorks

Cement Plants located in United States CemNet

Cement plant locations and information on United States can be found below For full access to the database, purchase The Global Cement Report™, 13th EditionIn cement plants there are many challenging applications to handle abrasive bulk materials Coperion customers can rely on proven competence and expertise in all process steps, eg dosing of additives like fly ash, slag sand, lime or gypsum, pneumatic conveying from clinker grinding to dispatch silos, or discharge of (hot) bypass dustCement – Coperion Today s are combined with OPC at the cement manufacturing facility (European model) or at the concrete batching plant (North American model) Inside the cement plant, the s can either be interground in the same process, or ground separately and blended In the case of separate grinding, one or more of the ingredients can be ground off siteCement plants of the future International Cement

LIVING NEAR A CONCRETE PLANT CCAA

Noise at a plant can be generated from activities such as: • delivery of cement, sand and gravel • handling, loading and mixing Concrete batch plant operators of concrete • truck movements • reversing beepers Dust at a plant can come from: • the delivery, storage and transfer of cement, sand and gravel • truck movements One big advantage of the dry sorbent injection system with fine milled Trona is its flexibility: it can be turned up or down to treat a wide range of acid gas concentrations This enables the plant to maintain a compliant 30day average at the stack with the ability to occasionally handle heavy loads and treat to nondetect levels if neededCase study: Cement plant in the USA SOLVAir®Cement plant applications are erosive, tough applications which can severely erode equipment not properly designed with this environment in mind Air pollution control in a cement plant is no different, and careful selection of technology, designed specifically with cement plants in mind, is the path to reduced maintenance and worryfree operationCement industry emission reduction with MECS®

Automation and Control in Cement Industries

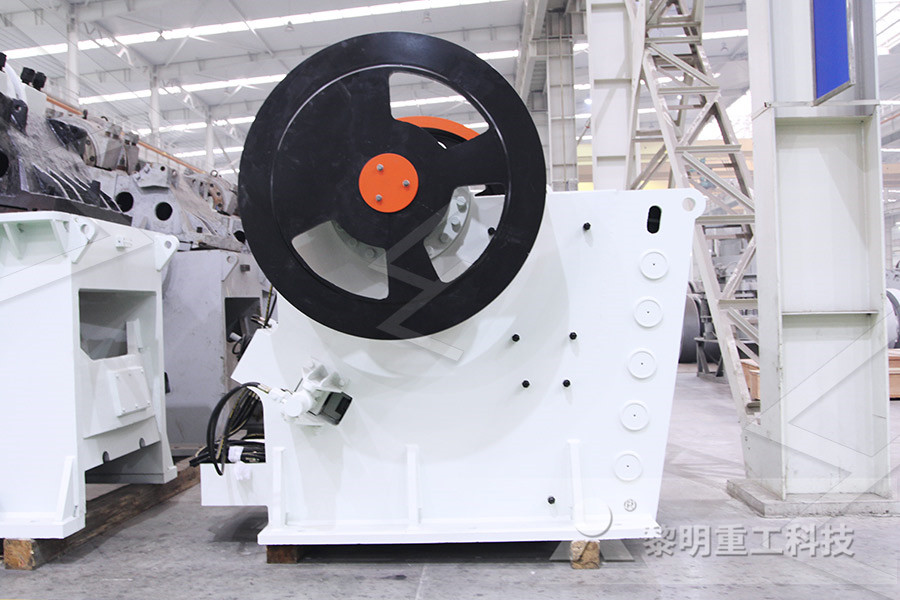

3 which can be ensured from iron ore, pyrite or blast furnace slag These materials are quarried or purchased and are transported on road, railway or conveyor to the cement factory The raw materials are usually crushed in the quarry, sometimes in the factory, up till the size as machinery can handle JEFFERSONVILLE, Ind (AP) — A southern Indiana port on the Ohio River is preparing to handle barges loaded with parts as heavy as 100 tons for a cement plantIndiana Port Readies To Handle Big Cargo For Cement The Donghae cement plant The Donghae Plant is the world’s largest cement plant with an annual clinker production capacity of 115 million t Located on a 2780acre site, including the quarry, the plant has had the quality of its product accredited by many expert institutions both in and outside of the country About Ssangyong CementSsangyong Cement challenged us to redesign the

Cementfree material paves the way for 'green'

Engineers have developed a composite binder made primarily of fly ash—a byproduct of coalfired power plants—that can replace Portland cement in concrete The material is cementless and Putting posts in the ground is an important step in building a fence, and pouring cement into the holes will keep your posts sturdy and protected After digging the hole, all you need to do is mix your cement and let it set In just 1 day, you can have posts in the ground that will last for a long How to Cement a Post in the Ground: 9 Steps (with In cement plants there are many challenging applications to handle abrasive bulk materials Coperion customers can rely on proven competence and expertise in all process steps, eg dosing of additives like fly ash, slag sand, lime or gypsum, pneumatic conveying from clinker grinding to dispatch silos, or discharge of (hot) bypass dustCement – Coperion

Cement plants of the future International Cement

Today s are combined with OPC at the cement manufacturing facility (European model) or at the concrete batching plant (North American model) Inside the cement plant, the s can either be interground in the same process, or ground separately and blended In the case of separate grinding, one or more of the ingredients can be ground off siteHow we can help Whether you are managing a project, automating a fuel handling system, selecting instruments for your clinker process or packaging a NOx gas cleaning solution for your environmental compliance program, our experienced process automation consultants can handle all measurement and control requirements of fullyintegrated cement plants:Cement Production: Focus on what really counts One big advantage of the dry sorbent injection system with fine milled Trona is its flexibility: it can be turned up or down to treat a wide range of acid gas concentrations This enables the plant to maintain a compliant 30day average at the stack with the ability to occasionally handle heavy loads and treat to nondetect levels if neededCase study: Cement plant in the USA SOLVAir®

LIVING NEAR A CONCRETE PLANT CCAA

Noise at a plant can be generated from activities such as: • delivery of cement, sand and gravel • handling, loading and mixing Concrete batch plant operators of concrete • truck movements • reversing beepers Dust at a plant can come from: • the delivery, storage and transfer of cement, sand and gravel • truck movements Cement plants are typically located central to the minerals required to make the cement, which saves the transportation costs and reduces the price of the cement Once the ore material to be used for cement has been mined, it is transported to the crushing/screening plant, where it is crushed and screened, to produce the desired particle Basic Things you should know about Cement Basic JEFFERSONVILLE, Ind (AP) — A southern Indiana port on the Ohio River is preparing to handle barges loaded with parts as heavy as 100 tons for a cement plantIndiana Port Readies To Handle Big Cargo For Cement

Cement Kilns: A Ready Made Waste to Energy

The Heidelberg Cement plant in Schelklingen, Germany It can handle bulky waste, as well as hazardous waste packed in drums, cans, plastic bottles, small containers etc An advanced treatment systems ensures that all steel is recycled, while the organic are mixed with sawdust to produce an 'impregnated saw dust' This material is sent to ABB Ability™ Expert Optimizer is a computerbased system for controlling, stabilizing and optimizing industrial processes Due to its stateoftheart optimization technologies the software helps you to make the best operational decisions accurately and consistently at all timesABB Ability Expert Optimizer for cement Advanced Putting posts in the ground is an important step in building a fence, and pouring cement into the holes will keep your posts sturdy and protected After digging the hole, all you need to do is mix your cement and let it set In just 1 day, you can have posts in the ground that will last for a long How to Cement a Post in the Ground: 9 Steps (with