AN OVERVIEW OF LIME SLAKING AGT Group

process of adding water to calcium oxide to produce calcium hydroxide is referred to as hydration process or lime slaking The hydration of CaO, commercially referred to as quick lime, is an exothermic process releasing a great quantity of heat This hydration process when done with just the right amount of water is called “Dry Hydration” When the quick lime or lime is reacted or comes in contact with water it readily absorbs this process is known as the Slaking of lime or Hydration of lime Quick lime – When the pure limestone is calcine in a kiln then we get quicklime Calcination – The process of heating limestone at 900ºC or above in a kiln is known as calcinationWhat Is Slaking Of Lime? Process Of Slaking 117 process or lime slaking The hydration of CaO, commercially referred to as quick lime, is an exothermic process releasing a great qu antity of heat This hydration process when done with just the right amount of water is called “Dry Hydration” In this case AN OVERVIEW OF LIME SLAKING AND FACTORS THAT

LIME SLAKING PROCESS AND ITS IMPACT ON

CaO to water Proper agitation of the lime slurry during slaking process is also very important A well designed mixer would ensure vigorous and continuous mixing at all the times during the slaking process This enables the system to maintain a homogeneous mixture inside the slaker, breaking up lumps of fine agglomerated Lime slaking is a heterogeIleous reaction between a solid phase (lime) and a liquid phase (water) and furthermore, lime is a natural product where the lime partides vary in Hize and in reactivity It is therefore difficult to model the kinetic properties of the slaking process The slaking process at ABB is a so called "d!'Y" processModeling an Industrial Lime Slaking Process As shown in Fig 3, slaking process through aspersion gives rise to heterogeneity in temperatures related to the distribution of the amount of water In those areas where lime is completely flooded, heat is faster dissipated, thus temperatures are lowerInfluence of the traditional slaking process on the lime

LIME SLAKING PROCESS AND ITS IMPACT ON

The quality of Ca(OH)2 depends on the slaking process andhydration parameters like water/lime ratio, slaking temperature and agitation rate A proper slakingprocess will cause an increase in particle surface area and create uniform particle distributionA lime slaking system for hydration of lime and removal of unwanted grit, particularly for formation of reactive slaked lime to be used in SO 2 scrubbing of effluent gases, comprising a series ofUSA Lime slaking and grit removal process 3 Slaking of Burnt Lime: The quick lime which is obtained by burning of lime stones slakes when exposed to the atmosphere This is known as the natural slaking or air slaking and it is a very slow process Hence the slaking is achieved by adding water to quick lime Following are the two methods of slaking: (i) Slaking to paste (ii) Slaking to Manufacturing Process of Lime: How to Manufacture

Lime Slaking Process RDP TECHNOLOGIES, INC

A lime slaking process is provided, whereby lime is delivered from a silo into a slaking vessel, and water is likewise delivered from one or more sources, into the slaking vessel, such that unreacted lime will go through a hydration process in an exothermic reaction, and wherein the temperature of the lime being slaked in the slaking vessel is monitored and controlled via a computer that LIME SLAKING Lime slaking is the process of converting quicklime to hydrated lime (CaO + H20 > Ca(OH)2) by mixing with water Lime slaking is an exothermic process which generates heat and creates steam Slaked or hydrated lime is often used in mining and process industries for raising pH or neutralising acidic solutionsLIME SLAKING SYSTEMS Bulk Handling Technologies Lime processing 221 Slaking process of the LCD A metallic tray of 45x30x8 cm was used for slaking 2 kg of the light calcined dolomite This slaking was conducted in an atmospheric environment at 20ºC and with discontinuous stirring The initial addition of 35 L of water, at ~20ºC, was added toDolomitic limes: evolution of the slaking process under

LIME SLAKING PROCESS AND ITS IMPACT ON

LIME SLAKING PROCESS AND ITS IMPACT ON FLOTATION EFFICIENCY AND OPERATION COST Mohamad Hassibi and Imman Singh Chemco Systems, LP [ protected] [ protected] surface chemistry of most minerals is affected by pH In general most minerals develop a positivesurface charge under acidic conditions and negative charge under alkaline conditionsA lime slaking system for hydration of lime and removal of unwanted grit, particularly for formation of reactive slaked lime to be used in SO 2 scrubbing of effluent gases, comprising a series of slaking vessels (10,12) for reacting CaO and water while agitating the reactants, a dilution mix tank (14) receiving a viscous slaked lime slurry from the vessels, diluent for the dilution tank Lime slaking and grit removal process utilized in SO2 Process Specialist Recausticizing Vector Process Equipment Inc 2079 Gordie Tapp Crescent Burlington, ON L7M 3T9 : dalesanchez@vectorprocess OVERVIEW The recausticizing process produces cooking liquor for the digester from recycled inorganic chemicals generated in the recovery boiler and lime kiln The process involves one21 Recausticizing Principles and Practice

Slaked Lime Structure, Preparation, Properties and

Calcium oxide is commonly known as quicklime The process of production of calcium hydroxide from lime is called slaking of lime as when a limited quantity of water is mixed with quicklime it disintegrates and crumbles The reaction involved is given below – CaO + H 2 O 🡪 Ca(OH) 2 3 Slaking of Burnt Lime: The quick lime which is obtained by burning of lime stones slakes when exposed to the atmosphere This is known as the natural slaking or air slaking and it is a very slow process Hence the slaking is achieved by adding water to quick lime Following are the two methods of slaking: (i) Slaking to paste (ii) Slaking to Manufacturing Process of Lime: How to Manufacture Lime slurry from hydrated lime powder is easily prepared by mixing the dry powder in water Quicklime on the other hand generates a lot of heat when it is mixed with water, in a process known as slaking, to produce slaked lime slurry ProProcess designs cater for hydrated lime slurrying or slaking of quicklime in specialised lime slakersLIME ProProcess Engineering

Why is there a hissing sound during 'slaking of lime

Calcium oxide reacts vigorously with water to produce slaked lime This reaction is called 'slaking of lime' This reaction is a highly exothermic reaction The hissing sound during this process is due to the heat produced The chemical equation for this reaction is as follows: CaO(s) + H2O(l) Lime slurry from hydrated lime powder is easily prepared by mixing the dry powder in water Quicklime on the other hand generates a lot of heat when it is mixed with water, in a process known as slaking, to produce slaked lime slurry ProProcess designs cater for hydrated lime slurrying or slaking of quicklime in specialised lime slakersLIME ProProcess EngineeringLime slaking process Burnt lime slaking process Adpap provides batch and continuous lime slaking processes for burnt lime The continuous slaking process includes powder handling, slaking, screening and milk of lime (MOL) slurry storageLime slaking process Turku Adpap Ltd

Slaked Lime Structure, Preparation, Properties and

Calcium oxide is commonly known as quicklime The process of production of calcium hydroxide from lime is called slaking of lime as when a limited quantity of water is mixed with quicklime it disintegrates and crumbles The reaction involved is given below – CaO + H 2 O 🡪 Ca(OH) 2 3 Slaking of Burnt Lime: The quick lime which is obtained by burning of lime stones slakes when exposed to the atmosphere This is known as the natural slaking or air slaking and it is a very slow process Hence the slaking is achieved by adding water to quick lime Following are the two methods of slaking: (i) Slaking to paste (ii) Slaking to Manufacturing Process of Lime: How to Manufacture LIME SLAKING PROCESS AND ITS IMPACT ON FLOTATION EFFICIENCY AND OPERATION COST Mohamad Hassibi and Imman Singh Chemco Systems, LP [ protected] [ protected] surface chemistry of most minerals is affected by pH In general most minerals develop a positivesurface charge under acidic conditions and negative charge under alkaline conditionsLIME SLAKING PROCESS AND ITS IMPACT ON

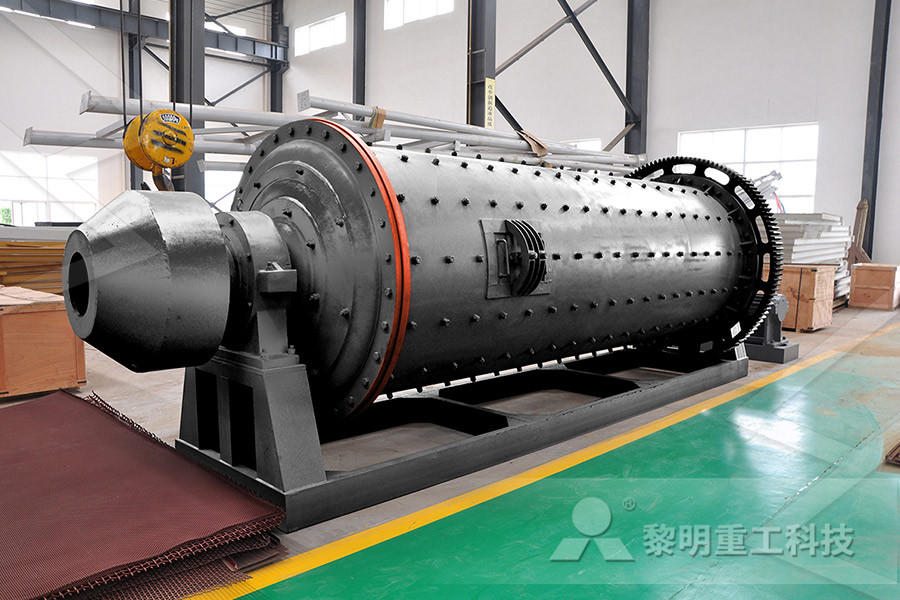

Lime Slaking Mill 911 Metallurgist

Lime Slaking Mill Lime Slaking Mill Post navigation Previous Next The art and science of lime production is usually not compatible with the chemical process using lime The occurrence of suitable limestone and fuel on, or near location is the exception rather than the rule Also, when the raw limestone is crushed to a suitable size for A fundamental study of the kinetics and mechanism of lime chemistry in the Bayer process has been undertaken To simplify the study and avoid interference from impurities, experiments were carried out in relatively pure systems Calcium hydroxide and calcium oxide, the solid reactants, were used in two different forms: rotating discs and powdersLime chemistry in the Bayer process Murdoch Influence of the traditional slaking process on the lime putty characteristics By Juan Ramón Rosell Amigó, Laia Haurie Ibarra, Antonia Navarro Ezquerra and Inma Rodríguez Cantalapiedra Abstract The influence of the slaking method on the characteristics of lime putties has been investigated There has been used the same raw lime, calcined Influence of the traditional slaking process on the lime

Lime Slaker Heating Direct Steam Injection Heating

The exothermic or released heat of reaction is captured and used to evaporate the excess slaking water High calcium quicklime readily reacts with water to form hydrated lime The reaction is highly exothermic and the process is known as "slaking"Slake process through short immersion (Z4)Unlike the two previous cases, the resulting product of this slaking process is not a lime putty, but powder lime The short amount of water involved in the process explains the high temperatures generated inside the mass (up to 350°C), which are kept above 100°C over the next 35 h since the Influence of the traditional slaking process on the lime