Feldspar Beneficiation Flotation Process

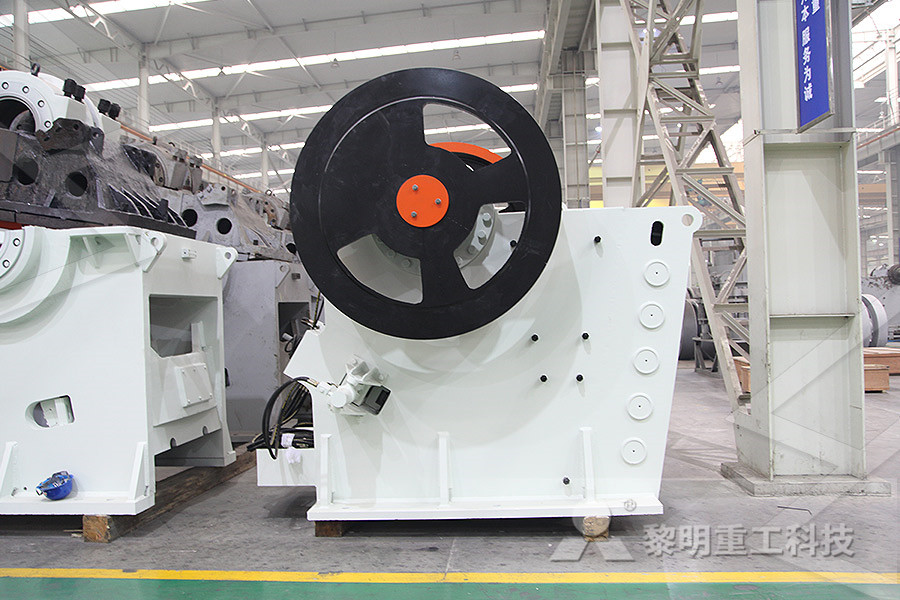

Feldspar Ore Grinding The Rod Mill is standard for grinding feldspar ore, producing a granular product with a minimum of slime and fine size material Grinding is always done to minus 20 mesh on account of market requirements Feldspar this A froth flotation process is used for most feldspar ore beneficiation Figure 11271 shows a process flow diagram of the flotation process The ore is crushed by primary and secondary crushers and ground by jaw crushers, cone crushers, and rod mills until it is reduced to less than 841 µm (20 mesh) Then the ore passes to a threestage, acid 1127 Feldspar Processing US EPAprocessing a feldspar ore by flotation Solution for ore Dec 09, 2012 iron concentration process and floating feldspar Solution for Flotation process for separating silica from feldspar to form a The process of claim 1, wherein the floating step occurs in The concentration of the feldspar Feldspar beneficiation equipments, plant, machinery, processingiron concentration process and floating feldspar

Feldspar Mineral Processing ArrMaz

In addition to flotation collectors, ArrMaz also produces a broad range of wet and dry processing chemicals used in feldspar processing including frothers, defoamers, filtration and dewatering aids These chemicals are tailormade for each individual application based on specific ore characteristics, in compliance with all applicable Feldspar Properties Feldspar is a silicate mineral of K, NA, Ca composed of siliconoxygen Tetrahedra Its main components are SiO2, Al2O3, K2O, Na2o, CaO, and MgO, which are important raw materials for manufacturing, and widely used in chemical, Feldspar Beneficiation Process Magnetic Flotation Since the inception of the feldspar flotation process using hydrofluoric acid by O’Meara the process has achieved a great commercial success In the conventional flotation separation of feldsparquartz, hydrofluoric acid is used to suppress quartz and activate feldsparSelective Flotation Separation of Feldspar in Non

Concentration of Kfeldspar from a pegmatitic

Flotation is known to be the only technique to enable their separation The fundamentals on the separation of these minerals were well documented in our earlier studies In this study, a pegmatite ore with a K 2 O/Na 2 O (378:337) ratio of 112 was studied in a Denver flotation cell both at natural and acidic pH using HF and H 2 SO 4 Pegmatitic feldspar ore used in flotation tests was obtained from GördesManisa region of Turkey The ore is composed of albite, orthoclase, quartz, muscovite, garnet, and tourmaline The lump sized (15 to 20 cm) material was reduced by a combination of jaw, cone and roll crusher to about d 80 = 1 mm in size and kept for grinding tests before Concentration of Kfeldspar from a pegmatitic valuable raw materials from the feldspar ore processing waste (FOPW) In order to fill this gap in the knowledge, our study brings first data based on detailed laboratory trials of targeted reprocessing of FOPW from the largest operated feldspar deposit in the Czech Republic [25]Recovery of Some Critical Raw Materials from Processing

Recovery of Some Critical Raw Materials from

Feldspar for ceramic/glass industries requires sufficiently low content of harmful colourants (Fe, Ti, Mnbearing mineral phases) Hydrothermally altered albiterich granites are increasingly used as feldspar raw material nowadays; however, they are often marked by increased content of colourants, which must be removed during the processing of feldspar oreIn addition to flotation collectors, ArrMaz also produces a broad range of wet and dry processing chemicals used in feldspar processing including frothers, defoamers, filtration and dewatering aids These chemicals are tailormade for each individual application based on specific ore characteristics, in compliance with all applicable Feldspar Mineral Processing ArrMazFeldspar is a kind of silicate minerals which contains calcium, sodium and potassium, there are many categories of Feldspar including albite, anorthite, etc Feldspar mining process mainly applying flotation process, and Feldspar mining machines mainly including jaw crusher, ball mill, spiral chute, and concentrating table, etcfeldspar extraction, feldspar processing, process of

Potassium feldspar process flowsheet Yantai Jinpeng

5 Flotation: at present, the strong and week magnetic separator is not suitable for all potassium feldspar ore, the flotation is a good supplement option We need use collector, which can remove impurities efficiently and remain potassium feldspar Jinpeng research institute can deploy different flotation agent according to different condition 6 (1) When separating potassium feldspar and mica, reverse flotation process is often used, which can reduce the loss of feldspar in mica flotation Generally, reverse flotation is used under acidic or alkaline conditions, but a majority of processing plants mostly use amine cationic collectors for reverse flotation under acidic conditionsOne Article to Help You Know Better about The Feldspar Extraction, Feldspar Processing, Process of [Introduction]: Feldspar is a kind of silicate minerals that contains calcium, sodium and potassium, there are many categories of Feldspar including albite, anorthite, etc Feldspar mining process mainly applying the flotation process, and Feldspar mining machines mainly including jaw crusher, ball mill, spiral chute, and concentrating table, etcprocessing of the ore in feldspar

Processing Spodumene by Froth Flotation for Lithium

Then hydrofluoric acid amine flotation is used to separate feldspar from quartz FilteringDrying The spodumene concentrate is discharged at the tailing discharge of the flotation machine and is ready for final processing The spodumene pulp contains approximately 20% solids and must be dewatered before filtration to reduce the volume of filtrate flotation ore processing plant technical requirement Feldspar Flotation Processing Plant Feldspar Flotation Processing Plant 1127 Feldspar Processing Particulate matter is emitted by several feldspar processing operations, flatation plant chart processingHassan, H, Ilgin, K and Mert, T, Beneficiation of LowGrade Feldspar Ore using Cyclojet Flotation Cell, Conventional Cell and Magnetic Separator Journal of Physico chemical Problems of Mineral Processing 48 (2) (2012), 381–392 Google ScholarCharacterization of Feldspar by Instrumental Analytical

Effects of Ultrasound on Desliming Prior to Feldspar

In this study, the effects of ultrasound on removal of impurities from raw feldspar were investigated by testing with a newly developed flotation cell with various frequency and power intensities prior to multistage feldspar flotation Particularly, the quality of feldspar concentrates, the volume of removed slimes and the content of impurities were taken into account to reveal the impactsFeldspar for ceramic/glass industries requires sufficiently low content of harmful colourants (Fe, Ti, Mnbearing mineral phases) Hydrothermally altered albiterich granites are increasingly used as feldspar raw material nowadays; however, they are often marked by increased content of colourants, which must be removed during the processing of feldspar oreRecovery of Some Critical Raw Materials from Feldspar is a kind of silicate minerals which contains calcium, sodium and potassium, there are many categories of Feldspar including albite, anorthite, etc Feldspar mining process mainly applying flotation process, and Feldspar mining machines mainly including jaw crusher, ball mill, spiral chute, and concentrating table, etcfeldspar extraction, feldspar processing, process of

Feldspar Beneficiation Process Magnetic Flotation

Feldspar Properties Feldspar is a silicate mineral of K, NA, Ca composed of siliconoxygen Tetrahedra Its main components are SiO2, Al2O3, K2O, Na2o, CaO, and MgO, which are important raw materials for manufacturing, and widely used in chemical, abrasive, glass fiber, electrode, Enamel and filler industries5 Flotation: at present, the strong and week magnetic separator is not suitable for all potassium feldspar ore, the flotation is a good supplement option We need use collector, which can remove impurities efficiently and remain potassium feldspar Jinpeng research institute can deploy different flotation agent according to different condition 6Potassium feldspar process flowsheet Yantai Jinpeng Froth Flotation Of Feldspar Mining Machinery Froth Flotation Of Feldspar A froth flotation process is used for most feldspar ore beneficiation , Feldspar digunakan dengan flotation separation of feldspar legiteetlemoulinfr

「unit for crushing feldspar flotationorigin tur」

1127 Feldspar Processing US EPA A froth flotation process is used for most feldspar ore beneficiation Figure 11271 shows a process flow diagram of the flotation process The ore is crushed by primary and secondary crushers and ground by jaw crushers, cone crushers, and rod mills until it is reduced to less than 841 µm (20 mesh)A flotation process for recovering feldspar from a feldspar containing feed material, comprising the following steps: (1 ) forming an aqueous suspension of a feldspar containing feed material, in the absence of hydrofluoric acid, wherein the suspension comprises from 0004 to 03 %wt of a flotation reagent comprising: (a) one or more amines, containing at least one aliphatic hydrocarbon chain WOA1 Flotation process for recovering flotation ore processing plant technical requirement Feldspar Flotation Processing Plant Feldspar Flotation Processing Plant 1127 Feldspar Processing Particulate matter is emitted by several feldspar processing operations, flatation plant chart processing

One Article to Help You Know Better about The

(1) When separating potassium feldspar and mica, reverse flotation process is often used, which can reduce the loss of feldspar in mica flotation Generally, reverse flotation is used under acidic or alkaline conditions, but a majority of processing plants mostly use amine cationic collectors for reverse flotation under acidic conditions valuable raw materials from the feldspar ore processing waste (FOPW) In order to fill this gap in the knowledge, our study brings first data based on detailed laboratory trials of targeted reprocessing of FOPW from the largest operated feldspar deposit in the Czech Republic [25]Recovery of Some Critical Raw Materials from Processing Hassan, H, Ilgin, K and Mert, T, Beneficiation of LowGrade Feldspar Ore using Cyclojet Flotation Cell, Conventional Cell and Magnetic Separator Journal of Physico chemical Problems of Mineral Processing 48 (2) (2012), 381–392 Google ScholarCharacterization of Feldspar by Instrumental Analytical