Washing The Material After Crushing Jaw Crusher

Washing Material After Crushing; Mineral Processing Metallurgy Britannica Mineral processing art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock or gangue it is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of Washing Material After Crushing Removal Washing Material After Crushing Remopany, as leading manufacturer and supplier of mining crushers in China, is located in Zhengzhou city, Henan Province Our main products are crusher machines for processing over 160 kinds of stones and ores in mining, quarry, construction, road and other industries washing the material after crushingwashing material after crushing Trio® Weir Brands Trio® comminution products incorporate world class design and engineering to provide solutions for crushing, screening, washing and material handling When sand and aggregates producer Pattison Sand had an ambitious plan for a new plant, washing material after crushing domyrolmexpl

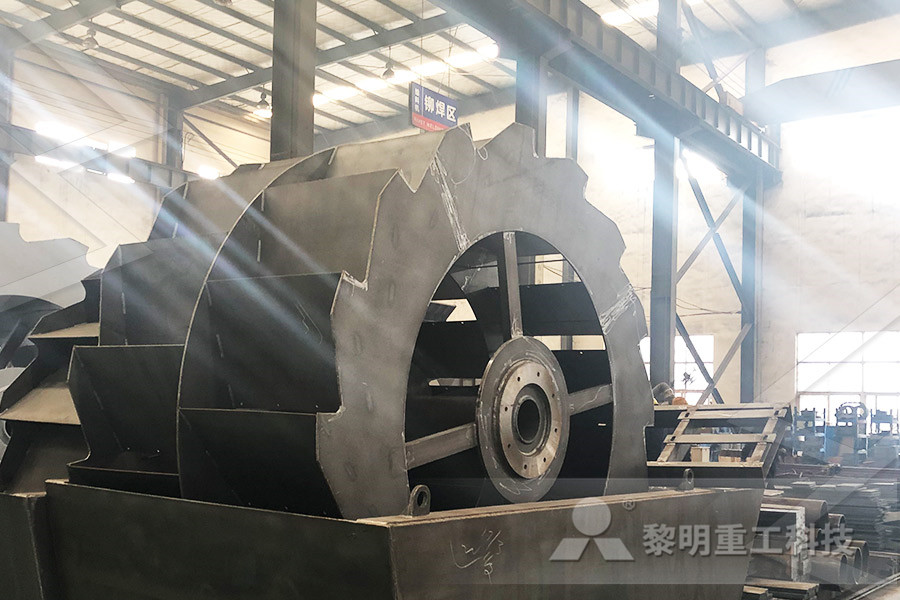

Stationary CrushingScreening and Washing Plant

Facility needs such as “stationary crushing plant, stationary crushing screening plant or stationary crushing screening and washing plant” are determined according to criteria such as the type of stones, feeding size, is the material clean or dirty etcHighspeed Friction Washer: After crushing material from enters the mouth, through the high speed on the axis of the blade flap and spray water to the common function of good cleaning effect Floating Washer 1: It used in cleaning pet flakes, make the flakes cleaner and whiterHigh Automatic Waste HDPE Plastic Crushing And Dewatering Equipment Filter Presses Material Crushing Material Washing and Screening Washing Systems for The Mining Industry In the past, dry screening was very common and accepted Today, to meet the needs of advancing world markets, there are now better options For mining Companies using washing and scrubbing for materials, they can Washing Systems for The Mining Industry Get

Waste plastic film crushing and washing line Polyretec

Waste PET Bottle Crushing Washing Recycling Machine Line ⅠWaste PET bottle crushing washing recycling machine line features: The waste PET bottle crushing washing recycling machine line is used for crushing, cleaning, separation of bottle cap and label, depriving of impurity and glue material, and drying for bottle flakesPE film washing equipment is an important step towards improving the environment and reducing carbon footprints Our film washing machine is designed to recycle different kind of dirty films , like green house film , agriculture film , ground film , woven sack bag , etc after washing , usually the material will go for further processpelletizing and then the granule can be used to make China Yatong Plastic Recycling Crushing and Washing Generally speaking, after a section of crushing, the cylinder size of the cylinder is used to feed the ore – 300mm; the size of the log washing machine is – 50mm For most of the laterite nickel ore, the nickelcobalt is mainly rich in – In the 3mm grain class, the grain size above +3mm is Extraction of Nickel Nickel Ore Mining Mining

Aggregate Crushing PlantHigh Safety High Efficiency

Aggregate crushing plant is a combination of feeding device, crusher device, conveying device, screening device and power system As a result of the great development of the basic construction and the reconstruction of the towns and the rapid rise of the highrise buildings, the oldstyle buildings die out, and the waste of the construction wastes is directly buried without treatment, Then it washing screen, fine material washer and product conveyors MEKA washing systems offer a range of screens and fine material washers options to fit your needs The screens are outfitted with strategically placed nozzles to scrub materials clean High capacity washers deliver the fine aggregates while chutes andONE WAY TO KEEP THE MATERIAL IN SPEC IS THROUGH Waste Hard Plastic crushing washing recycling machine line working flow After squeezing, material water content less than 15%, 20% higher in wovenbags pelletizing capacity than other suppliers Sales service Presale: we give customer the plastic recycling Waste Hard Plastic Crushing Washing Recycling

SUS304 Waste HDPE Plastic Bottle Crushing Washing

Highspeed Friction Washer: After crushing material from enters the mouth, through the high speed on the axis of the blade flap and spray water to the common function of good cleaning effect Floating Washer 1: It used in cleaning pet flakes, make the flakes cleaner and whiterFine material washers, also frequently named dewatering screws are utilized to clean and dewater fine aggregates typically minus 10 mm or 5 mm (3/8’’ or 4 mesh) to fine tune end products to meet specifications and to separate water soluble clay, silt, and micro sized fine particlesFine Material Washers MEKA Crushing Screening China Crushing Washing Recycling Machine manufacturers Select 2021 high quality Crushing Washing Recycling Machine products in best price from certified Chinese Machine For Plastic, Machine For Metal suppliers, wholesalers and factory on MadeinChinaChina Crushing Washing Recycling Machine, Crushing

Plastic washing machine|Crushing, Washing And

Good at water removal The residual moisture after drying could be around 13% Whole set of electric facility are with automatic startup to protect wires in safe You can opt to have 3 water tank, depending on how dirty material is9) Highspeed Friction Washer: After crushing material from enters the mouth, through the high speed on the axis of the blade flap and spray water to the common function of good cleaning effect 10) Floating Washer 1: It used in cleaning pet flakes, make the flakes cleaner and whiter Also is the necessary equipment of the bottle and bottle capChina Plastic Water Pet Bottle / Flakes Crushing PE film washing equipment is an important step towards improving the environment and reducing carbon footprints Our film washing machine is designed to recycle different kind of dirty films , like green house film , agriculture film , ground film , woven sack bag , etc after washing , usually the material will go for further processpelletizing and then the granule can be used to make China Yatong Plastic Recycling Crushing and Washing

China Waste PE PP Film Woven Bag Washing Line/

High speed friction washing machine: After crushing material from enters the mouth,though the high speed on the axis of the blade flap and spray water to the common function of good cleaning effect 7: The second time floating wash the bags and films: Floating washing tank: It used in cleaning film and bags,make the film cleaner, 8: Dry the Waste Plastic Pet Bottle Crushing Washing Drying Recycling Line / Machine / Plant, US $ 3000 3000 / Set, 1000, PET Bottle Washing Line, Hebei, ChinaSource from Hebei Fangtai Plastic Machinery Manufacture Co, Ltd on AlibabaWaste Plastic Pet Bottle Crushing Washing Drying Highspeed Friction Washer: After crushing material from enters the mouth, through the high speed on the axis of the blade flap and spray water to the common function of good cleaning effect Floating Washer 1: It used in cleaning pet flakes, make the flakes cleaner and whiterHigh Automatic Waste HDPE Plastic Crushing And Washing

Plastic washing machine|Crushing, Washing And Drying

Good at water removal The residual moisture after drying could be around 13% Whole set of electric facility are with automatic startup to protect wires in safe You can opt to have 3 water tank, depending on how dirty material isAfter washing recycling ,dirty pet material will remover label,oil,glue,sand etc New flakes can be make 2d or 3d pet fiber,filament yarn,pet strap,pet sheet ,pet China plastic pet bottle crushing washing drying recycling 9) Highspeed Friction Washer: After crushing material from enters the mouth, through the high speed on the axis of the blade flap and spray water to the common function of good cleaning effect 10) Floating Washer 1: It used in cleaning pet flakes, make the flakes cleaner and whiter Also is the necessary equipment of the bottle and bottle capChina Plastic Water Pet Bottle / Flakes Crushing Drying

China Waste PE PP Film Woven Bag Washing Line/ Used

High speed friction washing machine: After crushing material from enters the mouth,though the high speed on the axis of the blade flap and spray water to the common function of good cleaning effect 7: The second time floating wash the bags and films: Floating washing tank: It used in cleaning film and bags,make the film cleaner, 8: Dry the Suitable raw material: After recycling pelletizing machine: Crushing and compacting: the rotatory blades of compactor will cut the fed raw mateiral into pieces to reduce the size Frictional heating which is caused by high speed rotatory blades will heat and let scraps shrink just below their melt pointChina PP PE Agricultural Film Woven Bag Crushing Washing Output Type : Material will be processed by crushing, washing, dewatering, drying The humidity of final output could be within 510% Material will be processed by crushing, washing, dewatering, squeezing aggregating The humidity of final output could be within 2%China Small Capacity PP PE Crushing Washing Drying

China in House Waste Plastic Recycling Crushing Washing

China in House Waste Plastic Recycling Crushing Washing Machine, Find details about China HDPE Bottle Washing Line, PE Recycling Line from in House Waste Plastic Recycling Crushing Washing Machine Jiangsu Aceextech Machinery Co, LtdPP PE Film Crushing Washing Drying Recycling Equipment Line Plastic Washing Friction Washer Qr Code Labelled Paper Remover Plastic Film Recycling System, Find Details about LDPE Film Recycling Machine, PP Woven Bags Recycling Machine from PP PE Film Crushing Washing Drying Recycling Equipment Line Plastic Washing Friction Washer Qr Code Labelled Paper Remover Plastic Film PP PE Film Crushing Washing Drying Recycling Equipment The crushing system adopts wearresistant design to ensure that the system runs continuously for a long time 6 Hot washing machine effectively removes sticky glue, oil stains and some small impurities on the surface of bottle flakes, which is critical to the life of downstream China Mineral Water Bottleflakes Crushing Washing and