stages of extraction of uranium in the milling process

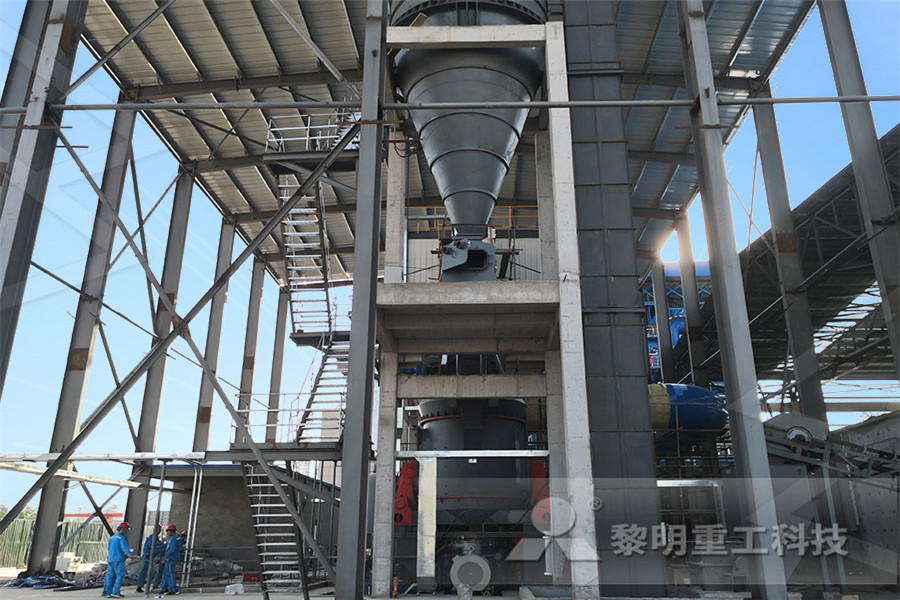

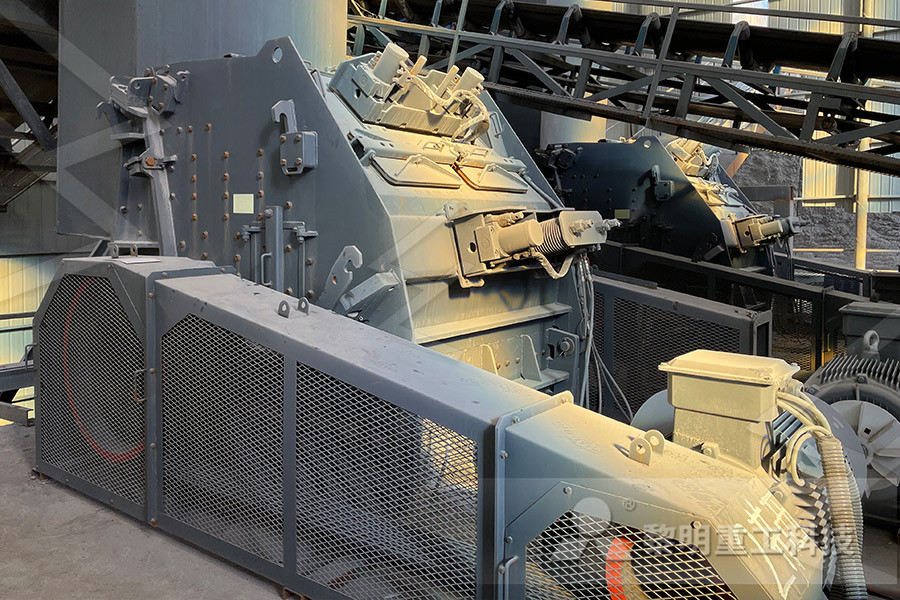

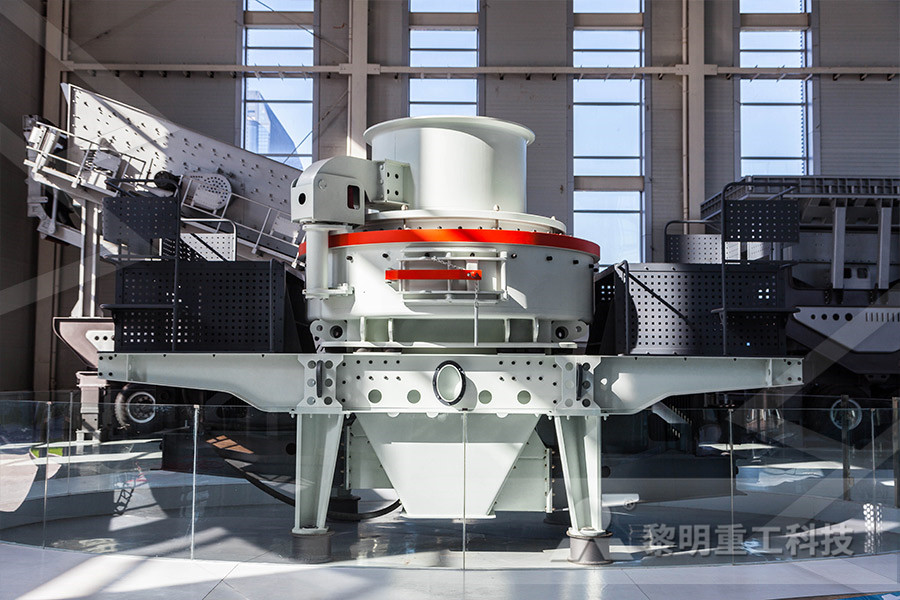

stages of extraction of uranium in the milling process Orano Wikipedia Orano (previously Areva) is a French multinational group specializing in nuclear power Stages Of Extraction Of Uranium In The Milling Process Milling Equipment: stages of extraction of uranium in the milling process A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grindingThe finished product can be controlled freely from 0 to 3000 meshStages Of Extraction Of Uranium In The Milling Process Uranium Solvent Extraction Mixer Tank showing airlift transfer of solvent between stages Steel shavings are added to the liquor in a 5′ x 10′ tank with a false bottom, to reduce all ferric sulphate to ferrous sulphate with an EMF of 275 to 300 Uranium Extraction Process 911 Metallurgist

Stages Of Extraction Of Uranium In The Grinding

Uranium Milling Ammonia Process Stages Of Uranium Extraction In The Milling Process EPA 908 I 7 8 URANIUM MINING MILLING THE NEED THE PROCESSES THE IMPACTS THE CHOICES ADMINISTRATORS GUIDE Prepared for WESTERN INTERSTATE ENERGY BOARDWINB formerly the Western Interstate Nuclear Board 2500 Stapleton Plaa 3333 Quebec Street Denver Colorado At the mill, uranium ore undergoes a variety of changes to turn it into a finished product: uranium powder, also known as yellowcake The milling process is so important that the US Atomic Energy Commission has helped mines establish mills close by to make it easier to process uranium Milling and Processing How Uranium Mining Works Stages Of Uranium Extraction In The Milling Process Milling and Processing How Uranium Mining Works uranium milling process product,15 Nov 2011, Milling and Processing Uranium mining is key in the creation of nuclear weapons, At the mill, uranium ore undergoes a variety of changes to turn it into a finished product uranium powder, also known Uranium Ore Test Equipment Machines trinitytrade

MINING, MILLING, CONVERSION, AND ENRICHMENT OF

optimized to use uranium enriched from about 3–5% in the uranium235 isotope Therefore, a number of chemical and physical separation processes are required to convert uranium ore into optimized nuclear fuel elements through the stages of mining, milling, conversion, and enrichment These form the “FRONT END” of the nuclear fuel cycle FIG 1 Generalized process for uranium extraction (c) Solidliquid separation and washing The pregnant liquor is separated from the leached ore, which is then washed to remove the remaining dissolved uranium A variety of separation techniques are available, including countercurrent decantation, filtration and separation by cyclonesMANUAL FOR URANIUM ORE PROCESSINGStages Of Extraction Of Uranium In The Milling Process Milling Equipment: stages of extraction of uranium in the milling process A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grindingThe finished product can be controlled freely from 0 to 3000 meshStages Of Extraction Of Uranium In The Milling Process

stages of extraction of uranium in the mill process

stages of extraction of uranium in the milling process Uranium mining is the process of extraction of uranium ore from the ground The worldwide production of uranium in 2015 amounted to 60,496 tonnes Kazakhstan, Canada, and Australia are the top three producers and together account for 70% of world uranium production Uranium ore is simply rock with elevated amounts of uranium in it Once the rock has been removed by open pit or underground mining it must be milled to separate the uranium from other constituents The milling process for uranium is similar to that used for other metals such as Cameco U101 MillingURANIUM MINING METHODS Based on the current understanding of uranium deposits in the Commonwealth of Virginia, extraction of uranium ore would use openpit mining, or underground mining, or a combination of both ()These general terms incorporate a large variety of design possibilities—there are as many methods of mining uranium as there are orebody sizes, shapes, and mineral constituents4 Uranium Mining, Processing, and Reclamation

MINING, MILLING, CONVERSION, AND ENRICHMENT OF

optimized to use uranium enriched from about 3–5% in the uranium235 isotope Therefore, a number of chemical and physical separation processes are required to convert uranium ore into optimized nuclear fuel elements through the stages of mining, milling, conversion, and enrichment These form the “FRONT END” of the nuclear fuel cyclestages of uranium extraction in the milling process Uranium Mining in Tanzania Legal and Human identified and about two projects are in exploration stage while one project has been developed to the mining stage Uranium mining and milling is the process of extracting uranium ores from the ground grinding and dissolving it in agrinding uranium autourdurocherfr Milling The mineralogy of the host rock and the choice of the extraction process influence the waste management problem Since characteristically uraniumbearing minerals are considerably softer than the quartz and silicate minerals that comprise the bulk of the gangue, the uranium, radium, and other minerals of interest tendNuclear fuel cycle Management of wastes from uranium

Uranium enrichment and extraction from ores

Uranium enrichment and extraction from ores MILLING OF URANIUM Process • of conversion of extracted uranium ore to a usable form called yellow cake is called milling The ore is first crushed to a fine powder by passing raw uranium ore through crushers and grinders This is further processed with concentrated acid, alkaline, or peroxide process The Guidebook is directed toward both management and technical personnel involved in planning and implementing a project It is part of a reports series on uranium mining and ore processing being developed by the IAEA's Division of Nuclear Fuel Cycle and Waste Management (NENF) These reports are referenced throughout the GuidebookGuidebook on the development of projects for uranium The goal of this study is to assess the lifecycle environmental impacts of uranium extraction routes: openpit mining, underground mining, and insitu leaching This study also compares their lifecycle assessment results to identify the most sustainable uranium extraction parative lifecycle assessment of uranium

Milling Process Uranium montagetapesnl

Stages Of Extraction Of Uranium In The Milling Process Uranium ores are normally processed by grinding the ore materials to a uniform particle size and then treating the ore to extract the uranium by chemical leaching A conventional uranium mill is a chemical plant usually built near the uranium mine Uranium milling extracts uranium using the stages of uranium extraction in the milling process At the mill uranium ore undergoes a variety of changes to turn it into a finished product uranium powder also known as yellowcake The milling process is so important that the US Atomic Energy Commission has helped mines establish mills close by to make it easier to process uranium ore and uranium milling ammonia processTailings are what is left over once the uranium has been removed from the ground rock and resemble fine sand They contain longlived radionuclides (such as thorium230 and radium226) produced from the decay of uranium, as well as trace metals like arsenic and nickel They also contain chemical residues from the milling processUranium Mining and Milling Canadian Nuclear Safety

Uranium mining milling: Assessing issues of

existing industrial process by diverting the operational — or even waste — stream for an additional extraction process For example, former uranium mining and milling facilities in Kyrghyzstan (Karabalta) will be converted to processing for gold Although heap leaching and byproduct recovery are fairly discrete and con The Mining and Milling Process • Delivery of Ore to Processing Plant (Mill) by trucks and/or conveyors • Pi dS d C hiPrimary and Secondary Crushing tidfi dto provide a fine powder • Leaching of Uranium from solid by acid or alkali (depending on type of host rock and the uranium minerals) – this seppyarates U from many insoluble impuritiesMINING, MILLING, CONVERSION, AND ENRICHMENT OF URANIUM MINING METHODS Based on the current understanding of uranium deposits in the Commonwealth of Virginia, extraction of uranium ore would use openpit mining, or underground mining, or a combination of both ()These general terms incorporate a large variety of design possibilities—there are as many methods of mining uranium as there are orebody sizes, shapes, and mineral constituents4 Uranium Mining, Processing, and Reclamation Uranium

Steps for preparing uranium production feasibility studies

have little or no experience in preparing feasibility studies in uranium production It is not a textbook which describes the geology, mining or processing of uranium This guidebook deals with the philosophy, basic principles and important factors in the various stages process The Guidebook is directed toward both management and technical personnel involved in planning and implementing a project It is part of a reports series on uranium mining and ore processing being developed by the IAEA's Division of Nuclear Fuel Cycle and Waste Management (NENF) These reports are referenced throughout the GuidebookGuidebook on the development of projects for uranium Solvent extraction has been applied to uraniumconcentrate production in Brazil At the first plant, uranium minerals associated with Zr and Mo were acid leached Extraction was carried out by a mixture of Alamine 336 and Alamine 304, followed by selective Zr, U, and Mo stripping At the currently Use of solvent extraction technique in Brazilian uranium

stages of procesing gold in the milling section

Gold extraction QueensMineDesignWiki IntroductionOre ClassificationComminution ProcessesProcess SelectionMill SizingConclusionReferences Once the gold ore has been removed from underground and brought to surface, an entirely new challenge begins in separating the gold from the waste material The separation process is particularly difficult due to the usually low quantity of gold relative to