how to improve the capacity of ball mill Prominer

Measures to Improve the Production Capacity of 01 One Change the ball mill itself 1 Increase the cylinder volume in a scientific way: For the ball mill with the same type and volume, decrease the thickness of the internal lining plate, so the machine weight is decreases and the material capacity is Measures to Improve the Production Capacity of Ball Mill Change the ball mill itself 1 Increase the cylinder volume in a scientific way: For the ball mill with the same type and volume, decrease the thickness of the internal lining plate, so the machine weight is decreases and the material capacity is How To Improve Capacity Of Ball Mills Ball mill plays an essential role in the mineral processing production line So, it is very important to improve the production capacity of ball mill for the users The purpose of the ball mill is to grind the materials to qualified particle sizeMeasures to Improve the Production Capacity of Ball

5 Ways to Improve the Ball Mill Efficiency Fote

Working site of ball mill grinding media refilling In addition to the grinding media proportion and frequency, other factors such as the grinding media material, the shape and so on can improve the ball mill efficiency Consult a professional engineer for details The optimized grinding media can improve the ball mill efficiency by about 30% Uniform feeding, and to add shoes right, ball mill can improve production capacity 2The structure of cement ball mill The length diameter ratio of ball mill is associated with production mode, for the open flow production system of grinding machine, in order to ensure the fineness of a qualified product, the length diameter ratio is 35 ~ 6 Several methods to improve the production capacity 7 mothods to improve the capacity of ball mill Use cement grinding aid Adding a little cement grinding aid to improve the effiency of ball mill grinding during the woking Since an enterprise uses the cement grinding aid, the increase rate of ball mill has been increased more than 10%, the power consumption per unit can be reduced by about 10% Factors That Affect Ball Mill Grinder Capacity And

Ten Ways to Improve the Grinding Efficiency of Your

Ten Ways to Improve the Grinding Efficiency of Your Ball Mill There are a lot of problems that most mineral processing plant will meet when operating the ball mill, such as low grinding efficiency, low processing capacity, high energy consumption, unstable product fineness of the ball mill So h Sandreturning ratio is the ratio between the amount of sand return of ball mill and the feeding capacity of raw ore, which can directly affect the productivity of the ball mill One way to improve the sandreturning ratio is to increase the feeding capacity of raw ore, another way is to reduce the shaft height of the spiral classifier10 Ways to Improve the Grinding Efficiency of Your Ball mill circuit classification system performance is considered here first because it provides the basis for subsequent characterization of ball mill breakage efficiency Major design and operating variables in closed circuit ball milling of a specified feed to a desired product size are summarized in Table 1How to Improve Ball Mill Performance 911 Metallurgist

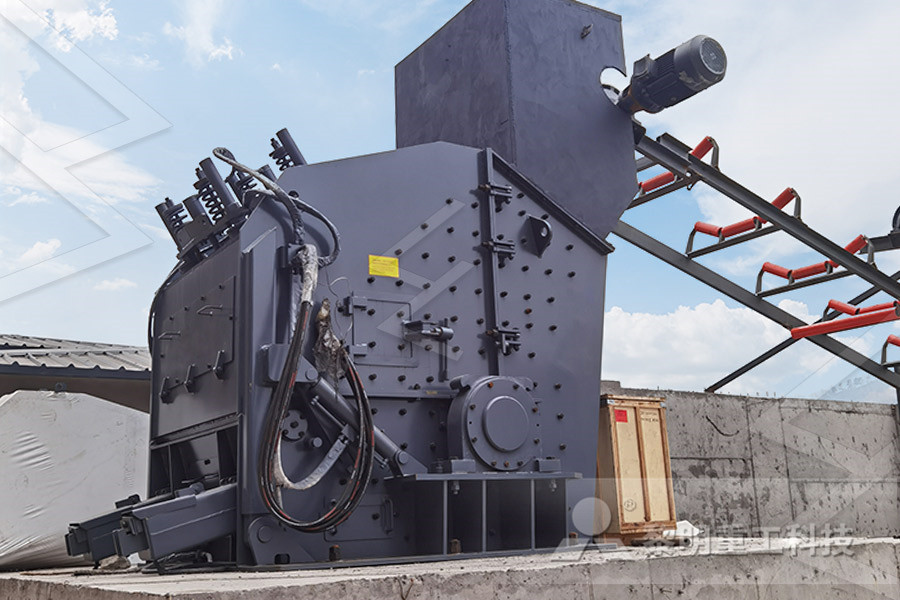

How to Improve the Production of Ball Mills?

Ball mill as a kind of popular grinding and ore beneficiation equipment is widely used in cement manufacturing, silicate products, construction materials, refractory and other industries It is what are good ways to improve capacity of cement ball mill upgrade in the case of an existing ball mill circuit to combigrinding with highpressure grinding rolls hpgr in this case, the hpgr will be installed before the ball mill and replace the first ball mill chamber, increasing the length of the second chamber upsides are good energy efficiency and a high output increasewhat are good ways to improve capacity of cement Measures to Improve the Production Capacity of Ball Mill Change the ball mill itself 1 Increase the cylinder volume in a scientific way: For the ball mill with the same type and volume, decrease the thickness of the internal lining plate, so the machine weight is decreases and the material capacity is increased At the same time, the energy consumption is lower, and the productivity how to increase the capacity of a mill

Enhancing the capacity of largescale ball mill through

The production capacity of the largescale ball mill in the concentrator is a crucial factor affecting the subsequent separation and the economic beneHow to improve the productivity and product quality of ball mill milling 2 Improve the quality of ball mill milling The relationship among the following three are: crushing before grinding is a prerequisiteIn this way, for China's cement factories, especially for small and medium cement plant, how to improve the yield and quality of cement has becomes a serious problemhow to improve the ball mill grinding There are two kinds of ball mill: wet ball mill and dry ball mill For dry ball mill, the humidity of input materials has a great impact on capacity and quality Materials that have too much water will unbalance the input and output quantity, leading to more materials left in ball millThe 6 Factors for Product Quality and Capacity of Ball

How to improve the grinding efficiency of the ball mill

The grinding efficiency of ball mill is low, the treatment capacity is low, the production energy consumption is high, the product fineness is unstable and so on, which are the problems that most concentrators will encounter How to effectively improve the grinding efficiency of ball mill is an important problem This article summarizes 10 ways to improve efficiency, if you are worried about Choose right speed to improve ball mill grinding efficiency Therefore, from the point of view of achieving the best economic index, it is required that the production capacity of ball mill is the highest, the power consumption per unit output is the smallest, and the wear consumption of grinding body and lining plate is the least Choose right speed to improve ball mill grinding As one of the commonly used mineral processing equipment, the quantity and proportion of steel balls in ball mill barrel not only affect the grinding efficiency and production capacity of ball mill, but also affect the ball mill's service life In the operation process, grinding efficiency of ball mill generally depends on the sum of the work done by each steel ball (the number of steel ball Add Steel Ball Correctly to Improve Ball Mill Grinding

improve energy consumption in the ball mill

Measures to Improve the Production Capacity of Ball For the ball mill with the same type and volume, decrease the thickness of the internal lining plate, so the machine weight is decreases and the material capacity is increased At the same time, the energy consumption is lower, and the productivity of the ball mill is prompted 2How to Improve Ball Mill Performance Oct 25, 2017 Ball mill circuit classification system performance is considered here first because it provides the basis for subsequent characterization of ball mill breakage efficiency Major design and operating variables in closed circuit ball milling of a specified feed to a desired product size are summarized in Table 1improve ball mill efficiency,impact crusher galenaHow to improve the productivity and product quality of ball mill milling 2 Improve the quality of ball mill milling The relationship among the following three are: crushing before grinding is a prerequisiteIn this way, for China's cement factories, especially for small and medium cement plant, how to improve the yield and quality of cement has becomes a serious problemhow to improve the ball mill grinding

Comparative Study on Improving the Ball Mill Process

The ball mill process parameters discussed in this study are ball to powder weight ratio, ball mill working capacity and ball mill speed As Taguchi array, also known as orthogonal array design, adds a new dimension to conventional experimental design, therefore, Orthogonal array (L9) was carefully chosen for experimental design to understand Choose right speed to improve ball mill grinding efficiency Therefore, from the point of view of achieving the best economic index, it is required that the production capacity of ball mill is the highest, the power consumption per unit output is the smallest, and the wear consumption of grinding body and lining plate is the least Choose right speed to improve ball mill grinding Ball mill is a common grinding machine It is also the key equipment in grinding industry Ball mill is suitable for grinding various materials with different hardness and humidity That's because it has two kind of grinding modes, dry process and wet process Customers can control the capacity and final products' fineness by adjusting the Ball Mill, Improve The Crushing Rate Of Ball Mill

Ball Mills an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall mill: Parameter JinPeng Others Working life: 810 years: 34 years: Quality: JinPeng design institute constantly pursuing creativity and breakthrough in technology, especially on modification, energy saving, improve the capacity of ball millBall mill Jinpeng Mining Magnetic Separation Techniques to Improve Grinding Circuit Efficiency – 2014 New Trunnion Magnet Technology Provides Significant Cost Savings Depending upon mill capacity, ball size and other parameters, Eriez will select and specify the appropriate construction featuresMagnetic Separation Techniques to Improve Grinding

Converting a ball mill from overflow to grate

One way of fully utilising the capacity of a ball mill is to convert it from an overflow to a grate discharge This can allow an operation to increase plant throughput or reduce the product size, which can each contribute to higher revenue, but there are several A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Ball Mill For Cement Plant /ball Mill With High Capacity Luoyang Zhongde Ball Mill Manufacturer Zhongde overflow ball mill sizes range from 5ft to High Capacity Cement Ball Mill for Cement Plant