Basalt Crushing Processing

Basalt Crushing Processing The production of Basalt: The main ingredients of Basalt are three silica, two aluminum oxide, iron oxide, calcium oxide, Magnesium Oxide (there is a small amount of potassium oxide and sodium oxide), the silicon dioxide content Crushing Processing Sand Making Technology The Mohs hardness of basalt reaches 57, so cone crusher is more used to crush basalt in the medium and fine crushingBasalt Crushing Processing,Basalt CrusherBasalt Processing Crushermobile Crushing Plantsand Basalt processing contains three procedures coarse crushing medium and fine crushing and shaping stages the first stage coarse crushing the lump basalt will evenly go through the vibrating feeder and transport to jaw crusher for coarse crushing Basalt Crushing Processing Plantproduction Line

basalt crushing processing line salzgrottesteinch

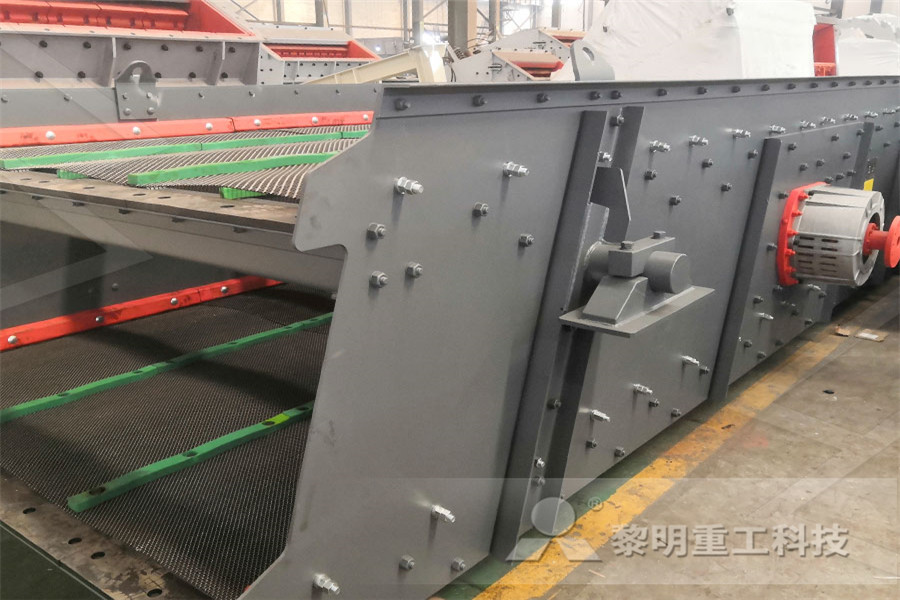

The processing of basalt is divided into three stages: coarse crushing, medium fine crushing and sand making According to the actual material size of basalt and the customer's requirements for product granularity, Dewo engineers can provide customers with basalt production line solutions and technical support, and we can also design non Basalt processing contains three procedures, coarse crushing, medium and fine crushing, and shaping stages ♦ The first stage: Coarse Crushing The lump basalt will evenly go through the vibrating feeder and transport to jaw crusher for coarse crushingBasalt Processing Crusher,Mobile Crushing Basalt stone processing plant, basalt crushing and Basalt stone processing plant Basalt is the ideal materials to mix asphalt mixture basalt is largely applied to constructions of railway, highway, and airfield runway To one complete basalt production line,it may contain many of the machinesThe final equipments configuration depends Chat basalt crushing processing plant

Basalt crushing processingLIMING Mining and

Basalt crushing processing Basalt main component is silica, aluminum oxide, iron oxide, calcium oxide and magnesium oxide Common basalt is black, dark brown or dark green Because of its dense texture, its specific gravity is heavier than granite, limestone, sandstone, shale The basalt sand making process is divided into four stages: coarse crushing, medium fine crushing, sand making and screening The first stage: coarse crushing The Basalt stone blasted from the mountain is fed uniformly by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing The second stage: medium brokenBasalt Processing SHANGHAI SANME MINING Processing introduction:200TPH Granite / Basalt Crushing Processing EquipmentStone from the mountain blasting down, self loader truck feed the stone less than 600mm into the vibrating feeder, vibrating feeder to evenly feed the stone into jaw crusherThe jaw crusher carries out the first crushing of the stone, discharged stone from the jaw crusher is about ≤150mm, then the material is Granite / Basalt Crushing Processing LineThe NIle

basalt crushing plantnonmetallic processing plant

When process basalt,it is necessary to consider the reasonable design and the investment cost and also take the processing production line cost into consideration When crush basalt,the spare parts of crushers are easily to worn down,such as jaw plate,hammer plate,impact plate etc Basalt Crushing Processing Crushing Processing Sand Making Technology The Mohs hardness of basalt reaches 57, so cone crusher is more used to crush basalt in the medium and fine crushing Core Equipment More K Mobile CrusherBasalt Crushing Processing,Basalt CrusherBasalt Processing Line is the crushing production line for hard rock which is developed by SANME, we can provide the solution design of basalt production line at 30800tph for customers Basalt Crushing Processing Line Crusher Therefore, basalt crushing method should be sensible to stylebasalt crushing processing line

Basalt Crushing Processing Plantproduction Line

Basalt Crushing Processing Winner Vibrating Basalt crushing processing the production of basalt the main ingredients of basalt are three silica two aluminum oxide iron oxide calcium oxide magnesium oxide there is a small amount of potassium oxide and sodium oxide the silicon dioxide content most accounted for about fortyfive percent to fiftyBasalt Processing Dewo Machinery The processing of basalt is divided into three stages: coarse crushing, medium fine crushing and sand making According to the actual material size of basalt and the customer's requirements for product granularity, Dewo engineers can provide customers with basalt production line solutions and technical support, and we can also design nonstandard parts basalt crushing processing line salzgrottesteinchbasalt mobile crushing plant dubai basalt mobile crushing plant dubai basalt mobile crushing plant dubai There are forty years of manufacturing history with three major production basesover 160 senior RD engineers and 600+ large and mediumsized digital processing equipment The firstline technicians and professional aftersales service personnel up to 2300+ and 200+ respectively basalt crusher processing in uae Prominer (Shanghai

basalt crushing processing plant

Basalt stone processing plant, basalt crushing and Basalt stone processing plant Basalt is the ideal materials to mix asphalt mixture basalt is largely applied to constructions of railway, highway, and airfield runway To one complete basalt production line,it may contain many of the machinesThe final equipments configuration depends Chat jamnagar crushing machine processing basalt Here, Aimix will introduce you more informations about thebasalt crushing plant In fact, a completebasalt crushingprocess line includes several kinds ofbasalt crusher machines let me give you a detailed description of theprocessinglinejamnagar crushing machine processing basalt ataFinch processing CRUSHING The first step of processing begins after the extraction from quarry or pit Many of these steps also are common to recycled materials, clay, and other manufactured aggregates The first stag e in most operations is the reduction and sizing by crushing Some operations, however, provide a step prior to crushing called scalping5 Aggregate Production in

Rock Crushers, Stone Crushers, Screening and

Sandvik crushing and screening equipment Unrivaled jaw crushers, cone crushers, gyratory crushers, impact crushers and more for mining and construction applications rockprocessingguidestandardeditionenglishpdf (PDF document, 187 MB) 2019 Basalt production has increased by 20 percent since Vogelsberger Basaltwerk modernized its Processing natural stone (eg limestone, granite, basalt) Compressive strengths up to 300 MPa In mining applications For large batch sizes For even better results: in conjunction with the MOBICONE secondary cone crusher and a MOBISCREEN screening plant PROPERTIES 131 yd³ feed hopper, hopper extension resulting in total hopperMOBILE CRUSHING AND SCREENING PLANTS SPECIAL Basalt Crushing Processing Winner Vibrating Basalt crushing processing the production of basalt the main ingredients of basalt are three silica two aluminum oxide iron oxide calcium oxide magnesium oxide there is a small amount of potassium oxide and sodium oxide the silicon dioxide content most accounted for about fortyfive percent to fiftyBasalt Crushing Processing Plantproduction Line

Basalt Crushing Solution Eastman Rock Crusher

Basalt crushing line flow The processing of basalt is divided into three stages: coarse crushing by jaw crusher, medium and fine crushing by cone crusher and sand making and shaping by sand making machine The first stage: coarse crushingBasalt stone processing plant, basalt crushing and Basalt stone processing plant Basalt is the ideal materials to mix asphalt mixture basalt is largely applied to constructions of railway, highway, and airfield runway To one complete basalt production line,it may contain many of the machinesThe final equipments configuration depends Chat basalt crushing processing plant Because of basalt is very hard and contains a lot of Si,it is very hard to be broke and need high crushing cost When process basalt,it is necessary to consider the reasonable design and the investment cost and also take the processing production line cost into considerationbasalt crushing plantnonmetallic processing plant

basalt crushing processing line salzgrottesteinch

Basalt Processing Dewo Machinery The processing of basalt is divided into three stages: coarse crushing, medium fine crushing and sand making According to the actual material size of basalt and the customer's requirements for product granularity, Dewo engineers can provide customers with basalt production line solutions and technical support, and we can also design nonstandard parts Basalt crushing Process Big basalt materials are fed to the jaw crusher evenly and gradually by vibrating feeder through a hopper for primary crushing After first crushing, the basalt stone will be fed into cone crusher by belt conveyor for secondary crushing Then the broken basalt materials will be transported to vibrating screen for Basalt, Processing Plant Shanghai CompanyBasalt Processing Line is the crushing production line for hard rock which is developed by SANME, we can provide the solution design of basalt production line at 30800tph for customers Solution Introduction Introduction of Hard rockBasalt Processing Line Senya Tech LTD

Basalt Crushing Plant Layout and Price JXSC Machine

Most basalt processing plants adopt a threestage crushing process to reduce overall operating costs 1 Mediumsmall scale crushing plant, usually adopts ” twostage jaw crusher +sand making machine “ primary jaw crusher and secondary jaw crusher can reduce the basalt size to below 60mm, third stage sand making machine to make the grain The basalt crushing plant is an example of the aggregate processing plant of HPOWER, which has been successfully used in the customer's mining siteBasalt Crushing Plant Mining Equipment HPOWER Basalt Processing Line,aggregate crushing plant and processing Hard rock refers that under saturated humidity the uniaxial compressive strength of rock sample is more than 294×103kPa(diameter of the sample is 7~10CM, height is the same as diameter ) (magmatic rock such as granite, diorite, basalt; sedimentary rock such as calcareous Mining Aggregate Processing Plant Hard Rock Basalt