Extraction of Nickel Nickel Ore Mining Mining

The laterite mining method generally uses openpit mining The ore body generally does not require rock drilling or blasting Nickel ore processing plant can directly use the excavator to shovel the ore The thinner ore layers are first collected by the bulldozer and then shovel nickel mining is divide into coppernickel mining and extraction of nickel from sulphide oreMining Methods For Nickel Ore Nickel Ore Mining Process Xinhai Nickel Ore can be divided into copper sulfide nickel ore and nickel oxide ore, flotation is the main beneficiation method when processing copper sulfide nickel ore, magnetic separating and gravity separating are the commonly auxiliary methodsMining Methods For Nickel Soby Nickel mining occurs through extractive metallurgy, which is a material science that covers various types of ore, the washing process, concentration and Nickel Mining and Processing: Everything you Need to

Nickel element extraction, mining technique – flash

The mining methods differ with respect to the type of ore being mined Since nickel is composed in two types of ores, both of them are mined differently The sulfide ores are mined using underground mining methods though openpit mining can also be done in early stagesANTAM conducts open pit mining method with a selective mining to produce high grade and low grade nickel ore Nickel ore is used for ore feed for Pomalaa ferronickel plant as well as being sold to domestic market ANTAM sun dries its mined nickel ore before being screened to be crushed into desired sizePT ANTAM Tbk Nickel The nickel content of laterites varies widely: at Le Nickel in New Caledonia, for example, the ore delivered to the smelter in 1900 contained 9 percent nickel; currently it contains 1 to 3 percent Mining With nickel found in two radically different types of ore, it is not surprising that the mining Nickel processing Britannica

Enhanced methods for nickel recovery from low

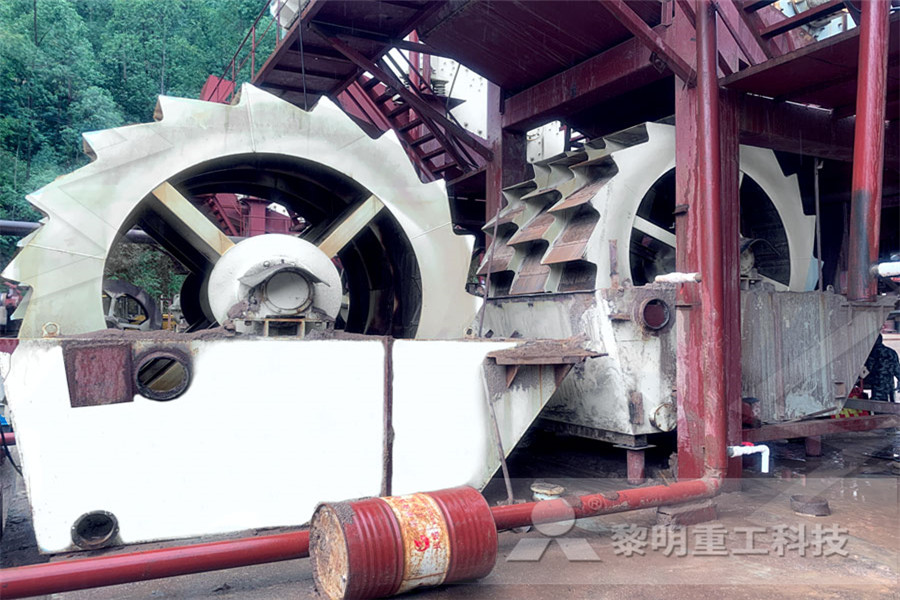

Concentrating the nickel ores usually takes place close to the mine site, and involves chemical and physical processes to crush the ore and separate the nickelbearing and gangue minerals Mining nickel directly is the obvious route to obtaining Lowgrade disseminated sulphide ore is mined from Mt Keith, a large openpit operation The ore is crushed and processed onsite to produce nickel concentrate Highgrade nickel sulphide ore is mined at Cliffs and Leinster underground mines and Rocky’s Reward openpit mine The ore is processed through a concentrator and dryer at LeinsterMajor Mines Projects Nickel West Mine2 天前 Nickel processing Nickel processing Extraction and refining: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used The major differences in equipment Nickel processing Extraction and refining Britannica

Nickel Mines, Nickel Extraction Process, Nickel

[Introduction]: Nickel ore can be divided into copper sulfide nickel ore and nickel oxide oreFlotation is the main beneficiation method when processing copper sulfide nickel ore, and magnetic separating and gravity separating are the commonly auxiliary methods Nickel Ore Mining Process Nickel ore mainly consists of coppernickel sulfide ore and nickel oxide ore, beneficiation and processing of both methods is completely different Coppernickel sulfide ore beneficiation methods: The most important is the flotation The magnetic and the gravity separation is usually secondary dressing methodNickel Ore Mining Process Equipment Flow Cases The mining methods differ with respect to the type of ore being mined Since nickel is composed in two types of ores, both of them are mined differently The sulfide ores are mined using underground mining methods though openpit mining can also be done in early stagesNickel element extraction, mining technique – flash

Nickel/Cobalt ore mining and processing operations,

gold mining centre of Murrin Murrin, approximately 60km east of Leonora 12 Background Anaconda Nickel NL (Anaconda) is the nominated proponent for the project Anaconda proposes to develop a nickel/cobalt project comprising opencut pits and a processing plant using a high pressure acid leach process to extract the metals from the ore For miners, the type of ore deposit—sulfide or oxide (or laterite, further subdivided into saprolites and limonites)—defines the whole value chain Depending on the specific circumstances, every mining method, processing route, and type of generated waste will bring its own challenges for meeting ESG requirements For smeltersHow clean can the nickel industry become? McKinsey1 A method for nickel concentration processing of a saprolite ore, characterized by comprising the steps of the following (1) to (4) (1) a saprolite ore is subjected to crushing processing to adjust the ore particle size to a size passing a sieve with an mesh opening of 50 mm (2) a crushed ore obtained in the step of the above (1) is subjected to drytype grinding processing of the surface METHOD FOR NICKEL CONCENTRATION

Nickel processing Extraction and refining Britannica

2 天前 Nickel processing Nickel processing Extraction and refining: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used The major differences in equipment are the use of highertemperature refractories and the increased cooling required to accommodate the higher operating temperatures in nickel Nickel occurs in essentially two ore types; magmatic sulphides and ('wet' or 'dry') laterites The sulphides typically are found hundreds of metres below ground with principle mineralisation The nickel laterite challenge Australian MiningLowgrade disseminated sulphide ore is mined from Mt Keith, a large openpit operation The ore is crushed and processed onsite to produce nickel concentrate Highgrade nickel sulphide ore is mined at Cliffs and Leinster underground mines and Rocky’s Reward openpit mine The ore is processed through a concentrator and dryer at LeinsterMajor Mines Projects Nickel West Mine

Raglan Nickel Copper Mine, Quebec Mining

Mining is predominantly conventional shovelandtruck open pit with an underground mine at Katinniq The first open pit mine in Zone 2, had a stripping ratio of 4:1 and benches in waste are 10m high while those in the ore are 5m high Underground mining uses a singlepass mechanised cutandfill method in 8–10mwide by 5mhigh panels[Introduction]: Nickel ore can be divided into copper sulfide nickel ore and nickel oxide oreFlotation is the main beneficiation method when processing copper sulfide nickel ore, and magnetic separating and gravity separating are the commonly auxiliary methodsNickel Mines, Nickel Extraction Process, Nickel Nickel Ore Mining Process Nickel ore mainly consists of coppernickel sulfide ore and nickel oxide ore, beneficiation and processing of both methods is completely different Coppernickel sulfide ore beneficiation methods: The most important is the flotation The magnetic and the gravity separation is usually secondary dressing methodNickel Ore Mining Process Equipment Flow Cases

Nickel/Cobalt ore mining and processing operations,

gold mining centre of Murrin Murrin, approximately 60km east of Leonora 12 Background Anaconda Nickel NL (Anaconda) is the nominated proponent for the project Anaconda proposes to develop a nickel/cobalt project comprising opencut pits and a processing plant using a high pressure acid leach process to extract the metals from the oreThe research method used is qualitative analysis method with case study that aims to obtain a direct description of the object of research on production operations M Hasbi Saleh PY 2019/02 DA 2019/02 TI Audit of Nickel Ore Mining Production BT 5th Annual International Conference on Accounting Research (AICAR 2018) PB Atlantis Audit of Nickel Ore Mining Production Atlantis Press1 A method for nickel concentration processing of a saprolite ore, characterized by comprising the steps of the following (1) to (4) (1) a saprolite ore is subjected to crushing processing to adjust the ore particle size to a size passing a sieve with an mesh opening of 50 mm (2) a crushed ore obtained in the step of the above (1) is subjected to drytype grinding processing of the surface METHOD FOR NICKEL CONCENTRATION

Nickel processing Extraction and refining Britannica

2 天前 Nickel processing Nickel processing Extraction and refining: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used The major differences in equipment are the use of highertemperature refractories and the increased cooling required to accommodate the higher operating temperatures in nickel Nickel occurs in essentially two ore types; magmatic sulphides and ('wet' or 'dry') laterites The sulphides typically are found hundreds of metres below ground with principle mineralisation The nickel laterite challenge Australian MiningLowgrade disseminated sulphide ore is mined from Mt Keith, a large openpit operation The ore is crushed and processed onsite to produce nickel concentrate Highgrade nickel sulphide ore is mined at Cliffs and Leinster underground mines and Rocky’s Reward openpit mine The ore is processed through a concentrator and dryer at LeinsterMajor Mines Projects Nickel West Mine

How clean can the nickel industry become? McKinsey

For miners, the type of ore deposit—sulfide or oxide (or laterite, further subdivided into saprolites and limonites)—defines the whole value chain Depending on the specific circumstances, every mining method, processing route, and type of generated waste will bring its own challenges for meeting ESG requirements The Cliffs Nickel Mine extracts a narrow near vertical nickel vein using a mining method of underhand bench stoping with paste backfill In 2014, at a depth of 400 m below surface, the Northern block of the mine began to experience squeezing within ore development At first the deformation was localised, within 30 m of theRecovery of the Northern Mining Block at Cliffs Nickel Mine