Rock Crusher Eastman Rock Crusher

Rock crushers have a wide range of suitable material to choose from, whether it’s soft or hard, or even very hard, rock crushers can reduce those large rocks into smaller rocks, gravel, or even rock dust In mining industry, with primary and secondary crushers handling coarse materials, and tertiary and quaternary crushers reducing ore Marcy® Double Roll Crushers are used in intermediate size reduction of medium hard to hard materials such as rock or ore, and can bridge the gap between laboratory and production outputs Models with 3,000lb per hour (1,361kg) or 8,000lb per hour (3,629kg) capacity reduce most materials Aggregate Crushers, for Rock, Ore Minerals Gilson Co It is designed for applications with hard and tough rock and offers high operational reliability Capacity range is between 130 450 t/h In comparison to other impact crushers – especially with hard materials – longer working life is achieved due to thicker wear linings Mineral Processing GmbH, Austria Hard Rock Impact

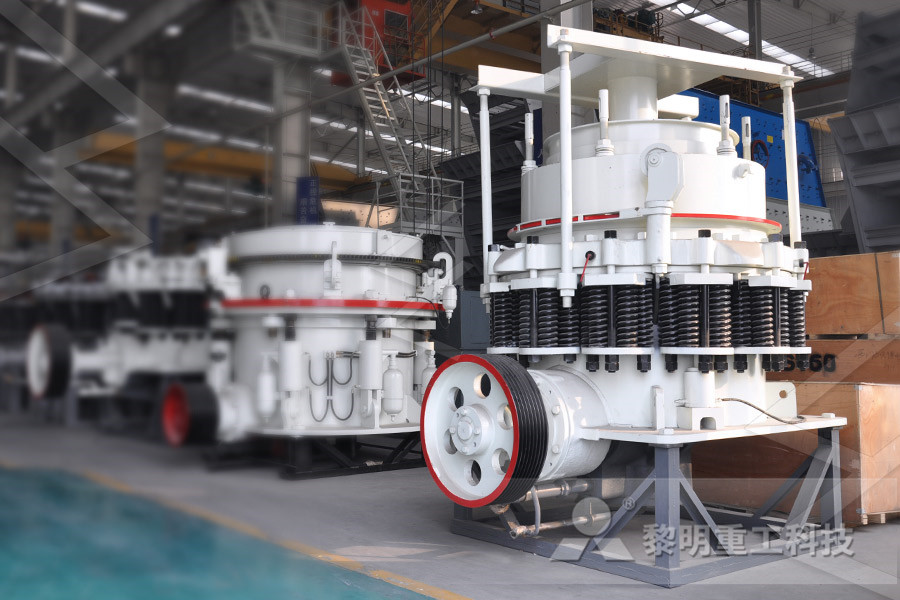

Mining Crushing Stone Hard Rock Impact Crusher Price Plant

Jaw rock crushers is an indispensability main machine for rock plants, mill plants, and quarry crushing plant The application is more widely than impact, but without the functions of impact crushers Cone crusher can crush hard, medium hard and many types of materials, mainly used for medium and fine crushing of materials Therefore, the Impact rock crushers use striking reduce the stone material size, not pressure The equipment is suitable for mining, metallurgy, cement, building materials, chemical industry, water, and electricity, etc Two types of impactors are the vertical shaft and horizontal impact crushersImpact Crusher Rock Crusher Machine Manufacturer JXSC Cone crushers are typically used for: Secondary or tertiary crushing in hard rock and gravels; Pebble crushing in mining circuits; Production of construction aggregate materials; Learn More About Rock Crushers With an array of different types, sizes, and purposes, choosing a rock crusher can quickly become overwhelming Add in the fact that a Should I Choose an Impact Rock Crusher or Cone Crusher?

Industrial Solutions Jaw crushers ThyssenKrupp

the swing jaw: singletoggle jaw crushers for a high throughput rate and double • toggle jaw crushers for extremely hard materials and abrasive rock Call on our services and you can count on a wealth of experience and constant innovative drive As a leadingNowadays, there are many different types of building materials crushers in the market, such as jaw crusher, cone crusher, impact crusher, hammer crusher and so on Inquire Now; Supply Building Materials Crushers Rock Crusher Supply Building Materials Crushers building material crushers hammer stone crusher Tracked crusher is a stable, safe and reliable crawler type of crushing and screening machine which is excellent for recycling construction waste, asphalt, bricks, and concrete, and other demolition materials, as well as mediumhard natural ore and glass Transport size, weight, and compact construction make transportation even more convenient, which gives the mobile crusher great flexibilityTracked Crusher for construction waste and concrete

rock crushers for hard materials Salzgrotte Stein

Marcy® Double Roll Crushers are used in intermediate size reduction of medium hard to hard materials such as rock or ore, and can bridge the gap between laboratory and production outputs Models with 3,000lb per hour (1,361kg) or 8,000lb per hour (3,629kg) capacity reduce most materials from 05in (13mm) feed size to minus No 10 (2mm) Chat Marcy® Double Roll Crushers are used in intermediate size reduction of medium hard to hard materials such as rock or ore, and can bridge the gap between laboratory and production outputs Models with 3,000lb per hour (1,361kg) or 8,000lb per hour (3,629kg) capacity reduce most materials from 05in (13mm) feed size to minus No 10 (2mm)Aggregate Crushers, for Rock, Ore Minerals Gilson rock crushers for hard materials Building Material Crusher , Hard Materials Crusher from Ugurmak, , rock or other materials up to the strength of 130 MPa More Price hard rock crushersRock rock crushers difficult

Mineral Processing GmbH, Austria Hard Rock

It is designed for applications with hard and tough rock and offers high operational reliability Capacity range is between 130 450 t/h In comparison to other impact crushers – especially with hard materials – longer working life is achieved due to thicker wear liningsThe jaw crusher is a popular alternative to the coarse rotary crusher because it can effectively handle large amounts of hard rock View details Single cylinder hydraulic cone crusher is widely used in metallurgy, construction, highway, chemical industry and building materials industry for medium crushing and fine crushingStone Crushers, Rock Crushers, Screening and Portable jaw crushers are most commonly used as primary crushers They are suitable for processing hard rock, soft rock and recycled materials Portable cone crushers are developed especially for secondary, tertiary and fine crushing with high productivity Portable cone crushers can reduce any rock types Global expertise, local supportNW Series™ portable crushers Outotec

Mining Crushing Stone Hard Rock Impact Crusher

Jaw rock crushers is an indispensability main machine for rock plants, mill plants, and quarry crushing plant The application is more widely than impact, but without the functions of impact crushers Cone crusher can crush hard, medium hard and many types of materials, mainly used for medium and fine crushing of materials Therefore, the rock crushing equipment list We offer different kind of crushers, whether it’s for primary crushing or secondary crushing stages, or use to crusher soft or hard materials there are Rock Crushing Sand Making Machine for Sale the swing jaw: singletoggle jaw crushers for a high throughput rate and double • toggle jaw crushers for extremely hard materials and abrasive rock Call on our services and you can count on a wealth of experience and constant innovative drive As a leadingIndustrial Solutions Jaw crushers ThyssenKrupp

Crushing Limestone Mobile Rock Crushers RUBBLE

Crushing Limestone Limestone is a common easy to crush sedimentary rock that is a soft to mediumhard Crushed limestone has a variety of uses from dense graded aggregates (DGA) to aggregates for concrete and asphalt materialsMarcy® Double Roll Crushers are used in intermediate size reduction of medium hard to hard materials such as rock or ore, and can bridge the gap between laboratory and production outputs Models with 3,000lb per hour (1,361kg) or 8,000lb per hour (3,629kg) capacity reduce most materials from 05in (13mm) feed size to minus No 10 (2mm)Aggregate Crushers, for Rock, Ore Minerals Gilson JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of mediumhard materials to smaller physical size Jaw rock crushers are capable of working with the mobile crushing station, underground crushing because of its related small volume Capacity: 11120TPH Max Feeding Size: 1201200mm ApplicationJaw Crusher Primary Crusher in Mining Aggregate

NW Series™ portable crushers Outotec

Portable jaw crushers are most commonly used as primary crushers They are suitable for processing hard rock, soft rock and recycled materials Portable cone crushers are developed especially for secondary, tertiary and fine crushing with high productivity Portable cone crushers can reduce any rock types Global expertise, local supportIntroduction to Combination Crusher Compound crusher is a kind of vertical crusher and highefficient rock crushers, widely applied in medium and fine crushing fields of high hard and super hard materials such as various rocks and ores, cement, refractory, bauxite aggregate, emery and glass materialscost of crushers various ores and medium hard Jaw crushers process medium to hard quarry rock or other materials by compressing it between the fixed jaw and the swing jaw woocommerceproduct Jaw Crushers, Jaw Crusher, Hard Rock Processing,

Mobile crushers and screens — Sandvik Mining and

Powerful, agile and fully mobile crushers We engineer the latest developments in the mining, quarrying and construction industries In order to bring the most powerful rock crushers, scalpers and screeners to the most difficult jobs, we have pioneered revolutionary machines with the AIHS SERIES With their high performance, high reduction percentages and perfect cubicalshaped final product, AGGRETEK secondary impact crushers are a great economical solution for crushing both mediumhard and hard materials such as river gravel, limestone and dolomiteThe grinding type of AIH series impact crushers provide a very competitive design for the asphalt recycling processHSI Crushers Aggretek Similarly, in rockdrilling, a hard rock demands a tough tool, whereas a soft rock demands a hard tool These facts are quite in agreement with the experience that a tough rock causes most abrasion on a hardened steel, but if the steel is soft, or workhardening has not occurred, then a hard brittle material may be very abrasiveRock Abrasion Crushers 911 Metallurgist

Crushing Equipment 101 Kemper Equipment

A rock crusher uses significant force to impact materials to the point of breaking or separating Most crushing equipment is designed with heavy plates or jaws used to apply pressure to whatever material have been fed into the chamber Crushers can be smaller and portable, but are usually built into a full circuit material handling system They are widely employed for crushing hard and abrasive materials in both the aggregate and mining industries Designed especially for the hardest material types, cone crushers are one of the best choices for crushing river gravel, basalt and granite, along with abrasive materials in the mining industry like iron, chrome, magnesite and copper oresMeka Crushers Rocktec