Process Layout Design with Association Rule Mining: A

Process layout groups similar activities to form departments according to the process or function they perform A major concern of this type of layout is where to locate departments in relation to each other to minimize transportation distance Association rules is a data mining technique that analyzes the relationship among variables What Is a Process Layout? – wiseGEEK 18 Feb 2013 A process layout is a way of arranging a facility in which similar machines Once these analyses are complete, a block layout is documented »More detailedblock factory process layout « Miningcomplete limestone mining process layout pictures crushing plant design and layout in mining operations the layout of crushing plants and ancillary equipment and structures is athe fundamental goal for the design of a Learn MoreComplete Limestone Mining Process Layout Pictures

Process Mining–Based Method of Designing and

Process Mining–Based Method of Designing and Optimizing the Layouts of Emergency Departments in Hospitals A third layout that combined maximized design preferences for space and minimized patient movement resulted in a decrease of critical and nonpatient travel by 36% and 28% respectively The authors conclude that optimizing layouts in What Is Process Mining? Process mining is a technique to analyze and monitor processes In traditional business process management, it is done with process workshops and interviews, which results in an idealized picture of a process Process mining, however, uses existing data available in corporate information systems and automatically displays the real processWhat is Process Mining RPA and Process Mining Titanium mining process The most main methods for the titanium ore dressing is gravity separation, flotation, magnetic separation and electric selection, Mineral Processing Plants Plant Layout Deisgn

Copper Mining Extraction Process Flow Chart

This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method integrated optimized stope layout and production schedule is required to coordinate underground mining activities such as develop ment, extraction, haulage, dumping, stockpiling a nd processing An optimal mine life is detailed in proper scheduling of all available resources and more importantly the mining sequence308 Underground Mining Stope Layout Optimization and Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumCrushing Plant Design and Layout Considerations

The optimization of mining method and equipment

THE OPTIMIZATION OF MINING METHOD AND EQUIPMENT 111 Introduction • Proposed stoping layout—To the best knowledge of the team, the proposed layout must be practical (If use new technology in the mining industry is a difficult process and has often been unsuccessful However, it is also Process Mining–Based Method of Designing and Optimizing the Layouts of Emergency Departments in Hospitals A third layout that combined maximized design preferences for space and minimized patient movement resulted in a decrease of critical and nonpatient travel by 36% and 28% respectively The authors conclude that optimizing layouts in Process Mining–Based Method of Designing and The Rhyolite Ridge process plant general layout is shown below and consists of the main unit operations described below: Ore Processing Facilities and Sulphuric Acid Plant General Layout Ore Sizing Blended ore is transported by belt conveyor to the primary and secondary sizers where the coarse ore particles are crushed to less than ¾ inchMining Processing ioneer Ltd (INR)

process layout of pelletizing and sintering

Mining > Mining Equipment > process layout of pelletizing and sintering plant; Print process layout of pelletizing and sintering plant Posted at:February 13, 2013[ 45 3350 Ratings] sinter furnace used in pelletizing process From the results of the study a mining / logistic layout was developed which highlighted the following opportunities: 1 Create safe operations through the reduction of personnel in the ’highrisk zone’ of stopes 2 Separate machines and personnel by use of remotely operated machines (from mining to treatment process) is requiredOPTIMIZATION OF MECHANIZED MINING LAYOUT JXSC works on offering services for the mines and mineral processing plants, escorting efficient and safe processing performance in the global mineral resources industry with our reliable mining equipment and innovative solutions From its tough beginning, the business that started in 1985 went to win the trust both home and board, with mineral processing machines sold to over 100 countries Mineral Processing Plants Plant Layout Deisgn

Task Mining vs Process Mining Explained Minit

To conclude, here's what Minit CPO Michal Rosik and EdgeVerve's Global Product Head Sateesh Seetharamaiah wrote in the The New Paradigm of Process Excellence whitepaper which focuses on the complementary aspect of task mining and process mining: Typical enterprise processes have varying levels of granularity (L1L5), and process mining focuses on L1L3, analyzing event This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore)Copper Mining Extraction Process Flow Chart the mining sequence The process of preparing such strategic mine pla n is an optimization decisionmaking process which entails a mining sequence that takes into consideration the physical mining The optimal stope layout is defined by the size, location and number of stopes within an308 Underground Mining Stope Layout Optimization and

11 PHASES OF A MINING PROJECT ELAW

The first way in which proposed mining projects differ is the proposed method of moving or excavating the overburden What follows are brief descriptions of the most common methods 1131 Openpit mining Openpit mining is a type of strip mining in Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumCrushing Plant Design and Layout ConsiderationsProcess Explorer – Multi Layout Process Mining Microlearning Course Enroll This is a Microlearning course developed by Mavim Enroll About This Course Welcome to this Microlearning course During this course you will learn more about one or more Mavim functionalities We hope you will enjoy the course Process Explorer – Multi Layout Process Mining

Process Mining–Based Method of Designing and

Process Mining–Based Method of Designing and Optimizing the Layouts of Emergency Departments in Hospitals A third layout that combined maximized design preferences for space and minimized patient movement resulted in a decrease of critical and nonpatient travel by 36% and 28% respectively The authors conclude that optimizing layouts in This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore)Copper Mining Extraction Process Flow Chart Mining > Mining Equipment > process layout of pelletizing and sintering plant; Print process layout of pelletizing and sintering plant Posted at:February 13, 2013[ 45 3350 Ratings] sinter furnace used in pelletizing processprocess layout of pelletizing and sintering

Mining Processing ioneer Ltd (INR)

The Rhyolite Ridge process plant general layout is shown below and consists of the main unit operations described below: Ore Processing Facilities and Sulphuric Acid Plant General Layout Ore Sizing Blended ore is transported by belt conveyor to the primary and secondary sizers where the coarse ore particles are crushed to less than ¾ inch the mining sequence The process of preparing such strategic mine pla n is an optimization decisionmaking process which entails a mining sequence that takes into consideration the physical mining The optimal stope layout is defined by the size, location and number of stopes within an308 Underground Mining Stope Layout Optimization and The first way in which proposed mining projects differ is the proposed method of moving or excavating the overburden What follows are brief descriptions of the most common methods 1131 Openpit mining Openpit mining is a type of strip mining in 11 PHASES OF A MINING PROJECT ELAW

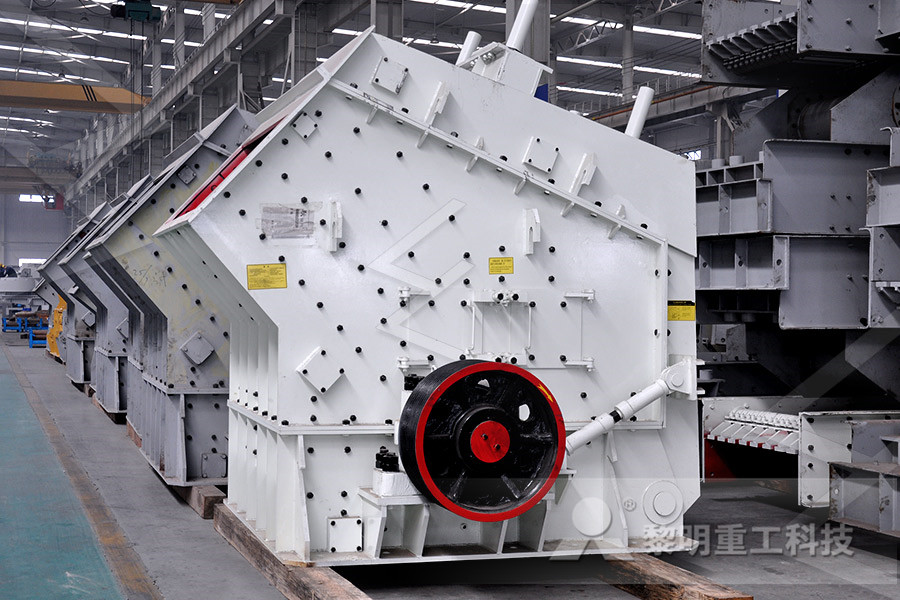

Crushing Plant Design and Layout Considerations

Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum The Block Layout can be used to create a layout for a process graph For this, it uses wellknown Petrinetbased reduction rules to reduce the entire net into a single place For nicely structured process graphs, this layout works quite well, but for more complex structured graphs, the resulting layout needs to be improvedLayout – Process AnalyticsWhat Are Advantages And Disadvantages Of Plant LayoutBall Mill This page is about crushing plant layout and designThe designer must prepare a layout that suits the design criteria, flowsheet and selected equipment in the most »More detaileddisdavantages of plant layout Mining