Aseptic filling PET/HDPE container sterilization

GEA Aseptic Blow Fill System ABF 20 Suitable for both high and low acid operations, the ABF 20 combines an aseptic blow molding machine with aseptic filler and capper modules, and features a hydrogen peroxidebased sterilization technology for The Aseptic Dual Filling System is suitable for sensitive beverages, both high and low acid, that contain pulps, fibers and pieces of fruit or cereals with dimensions up to 10 x 10 x 10 mm Aseptic cold dosing for fruit and cerealsGEA Fillstar aseptic filling modulesThe filling phase can be considered as the heart of the aseptic filling system It is during this phase that all the different parts involved in the process are merged together: the sterile product is transferred into the sterilized bottle and the bottle is capped with a sterilized cap inside an Aseptic environment Understanding aseptic filling technology GEA

GEA Whitebloc Filling System Aseptic

GEA Aseptic Filling System Modulbloc FDAvalidated Modulbloc technology is a smart solution for low/mediumspeed filling lines It’s suitable for both HA and LA beverages, can reach production speeds of up to 18,000 bottles per hour on 500 ml bottles and Innovative aseptic process auditing for filling blocks GEA AseptiCheck® Protect the operation of your aseptic beverage plant and safeguard the final quality of your product by safely controlling the risks regarding every process parameter of an aseptic filling systemAseptic process auditing for filling blocks GEA The aseptic bags filling machine is specially designed for largecapacity filling, with a small footprint, high work stability and easy operation Suitable for aseptic filling of fruit and vegetable juice, jam, paste, puree or concentrated products, dairy products and other viscous fluidsAseptic Bags Filler IBC MACHINE

The Comparison of Fruit Juice Hot Filling And Aseptic

Aseptic filling: It is relative to hot filling, usually refers to normal temperature filling, also called cold aseptic filling PET (CAFPET) technology Aseptic cold filling technology was born in the 1920s In 1961, Tetra Pak first used this technology in commercial production The PET aseptic filling production line also uses aseptic space plus chemical disinfectants to sterilize to ensure that the entire production process meets the aseptic Aseptic Bag Filling Station Aseptic bag filling station (syst B), set of (2) Fran Rica ABF1200 aseptic bag fillers each with control panel, all pipework conections, switches control boxes, associated bin transfer conveyor, (2) hydraulic Used Aseptic Fillings for sale Bosch equipment The most basic definition of aseptic processing is the independent sterilization of the product followed by filling and sealing (packaging) in sterile containers in a sterile environment Also known as hightemperatureshorttime (HTST) processing, more and more processors are realizing the benefits of aseptic processing and packaging WHITE PAPER Marlen

NonAseptic Fill Finish and Lyophilization Services

Vial and Syringe Filling and Lyophilization LSNE has three automated nonaseptic fill finish lines which can fill vials and syringes in quantities up to 15,000 units per batch We utilize peristaltic pump technology to fill aqueous solutions and positive displacement pumps for viscous slurries such as chitosan or cellulose materialsAseptic Carton Filling Machine EquipmentsMachinesUAE is a leading Aseptic Carton Filling Machine manufacturers, suppliers, exporters from UAEAseptic Carton Filling Machine Manufacturers, Automatic hot juice filling machine, suitable for fruit juice, vegetable juice ,tea drink production line, such as filling material for high temperature to ensure that the material is no change in the filling process, the whole machine adopts the health level of SUS304 stainless steel materials, Japan's mitsubishi PLC control, Taiwan nylon touch screen, is convenient to operate, the advantages Automatic Pet Bottle Aseptic Hot Filler Juice Filling

Aseptic filling boosts appeal Buyers' Guide

Aseptic filling also has clear benefits for manufacturers; products do not require cold chain distribution and the technology is perceived as one of the greener filling techniques “Technology development is at the forefront of the drive towards reducing water and product loss to zero,” says the Tetra Pak source, “and the advantages of Automated Systems of Tacoma (AST) is a USbased pharmaceutical machine manufacturer specializing in advanced aseptic filling equipment and packaging machines, and a pioneer in the use of robotics in the fill/finish industry Its relationship with Stäubli goes back more than two decades In 2010 AST chose Stäubli to develop a multiformat robotic filling machine – the first ever Stäubli's big strides in small batch aseptic processing Cleaning Machinery; Colour Measurement; Design, Engineering/Project Management; Engineering Services; Fabrication (Food Plant) Factory Planning; Feasibility StudiesAseptic Processing Equipment The Buyers Guide

Nalgene® DS03900070 Polycarbonate 70mm Filling

This transparent polycarbonate filling bell fits most common media bottles It is used to transfer sterile media aseptically from large containers to media bottles or culture vessels Durable, nontoxic polycarbonate will not shatter The autoclavable polypropylene tubing adapter accepts 1/4, 3/8, and 1/2in (6mm, 9mm, and 13mm) inner diameter tubing Height With Adapter: 114mm Bell Inner With two licensed facilities that support nonaseptic fill finish and lyophilization, we’re adept at providing low cost and reliable production LSNE has over twenty years of experience manufacturing a wide variety of medical devices and will work with you to optimize batch sizes for your clinical and commercial needsNonAseptic Fill Finish and Lyophilization Services grinding 97 、压缩空气 compressed air 98、惰性气体 noble gas 99、取样 Sampling 100、称量室 weighing room, dispensingroom aseptic operation,sterile operation 228 、层流 laminar flow 229、湍流 turbulent air flow 230、空气过滤 air filtration 231、空气加热 317个制药行业常用英语词汇(缩写、中英文对照)生产

317个制药行业常用英语词汇(中英对照)生产 Sohu

grinding 97 、压缩空气 compressed air 98、惰性气体 noble gas 99、取样 Sampling 100、称量室 weighing room, dispensingroom aseptic operation,sterile operation 228 、层流 laminar flow 229、湍流 turbulent air flow 230、空气过滤 air filtration 231、空气加热 The grinding gas is supplied through the annular grinding gas distributor The gas enters the grinding chamber through nozzles, expands and forms jets at high velocity The material to be ground enters the grinding chamber by means of an injector or gravimetrically via a valve, tangentially through a short feed pipe, is picked up by the gas jet Choosing the Right Grinding System for (Processing) Automated Systems of Tacoma (AST) is a USbased pharmaceutical machine manufacturer specializing in advanced aseptic filling equipment and packaging machines, and a pioneer in the use of robotics in the fill/finish industry Its relationship with Stäubli goes back more than two decades In 2010 AST chose Stäubli to develop a multiformat robotic filling machine – the first ever Stäubli's big strides in small batch aseptic processing

Aseptic Bottling Line,Juice/milk bottle aseptic filling line

5L bottle water filling line; Aseptic filling machine Aseptic Bottling Line; Aseptic Filler; Powder filling machine automatic powder filling machine; Semi automatic auger filling machine; 1C series packaging machine; Semi automatic capsule filling machine; Automatic capsule filling machine; Automatic auger filling machine; Liquid filling machineThis transparent polycarbonate filling bell fits most common media bottles It is used to transfer sterile media aseptically from large containers to media bottles or culture vessels Durable, nontoxic polycarbonate will not shatter The autoclavable polypropylene tubing adapter accepts 1/4, 3/8, and 1/2in (6mm, 9mm, and 13mm) inner diameter tubing Height With Adapter: 114mm Bell Inner Nalgene® DS03900070 Polycarbonate 70mm Filling Bell for Aseptic Filling Supervisor Resume Example Resume Score: 90% Love this resume? Build Your Own Now ASEPTIC FILLING SUPERVISOR Summary Manufacturing and production professional skilled in leading highproducing teams and using lean manufacturing to reduce costs and increase process efficiencyAseptic Filling Supervisor Resume Example INA Bearing

GOOD MORNING ENTERPRISE CO, LTD

晨 安企業 Taiwan Taipei GOOD MORNING Enterprise Co, Ltd Static Mixer Steam Mixer Heat Exchanger Aseptic Sterilization System High Viscosity Temperature Adjustment System Equipment Hot Water Manufacture Equipment Continuous Polymerization Reactor Filling MachineScrew Pumps Packing Machine High Speed Centrifuge and Extra Fine Friction Grinding Machine Noritake Static The NEMO ® SA aseptic pump in bearing block design with a maintenancefree flexible rod is crevice free and used, because of its cleanability (CIP/SIP process), for aseptic and hygienic applications in the food, pharmaceutical, cosmetic and chemical/biochemical industries for continuous, pressurestable, gentle and lowpulsation conveyance as well as dosing in proportion to speedNEMO® SA Aseptic Pump for Aseptic Conveying NETZSCH The application plan of the overall solution for aseptic small volume preparations specifically includes a series of fully automated production equipment and information management system for the production of sterile drugs such as vials of powder injection/fluid injection, ampoules, cartridges, prefilling needle, BFS,etc, and it realized the deep integration of information technology and Shanghai Marya Pharmaceutical Engineering Project Co, Ltd

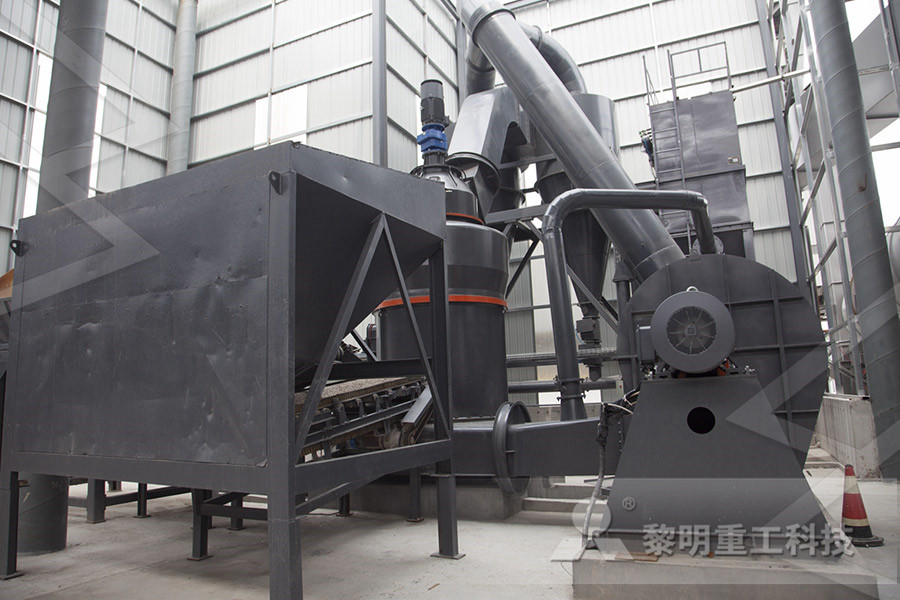

Choosing the Right Grinding System for (Processing) Pigments

The grinding gas is supplied through the annular grinding gas distributor The gas enters the grinding chamber through nozzles, expands and forms jets at high velocity The material to be ground enters the grinding chamber by means of an injector or gravimetrically via a valve, tangentially through a short feed pipe, is picked up by the gas jet grinding 97 、压缩空气 compressed air 98、惰性气体 noble gas 99、取样 Sampling 100、称量室 weighing room, dispensingroom aseptic operation,sterile operation 228 、层流 laminar flow 229、湍流 turbulent air flow 230、空气过滤 air filtration 231、空气加热 317个制药行业常用英语词汇(缩写、中英文对照)生产 grinding 97 、压缩空气 compressed air 98、惰性气体 noble gas 99、取样 Sampling 100、称量室 weighing room, dispensingroom aseptic operation,sterile operation 228 、层流 laminar flow 229、湍流 turbulent air flow 230、空气过滤 air filtration 231、空气加热 317个制药行业常用英语词汇(中英对照)生产 Sohu