Iron Ore Crushing And Screening Processes Costarica

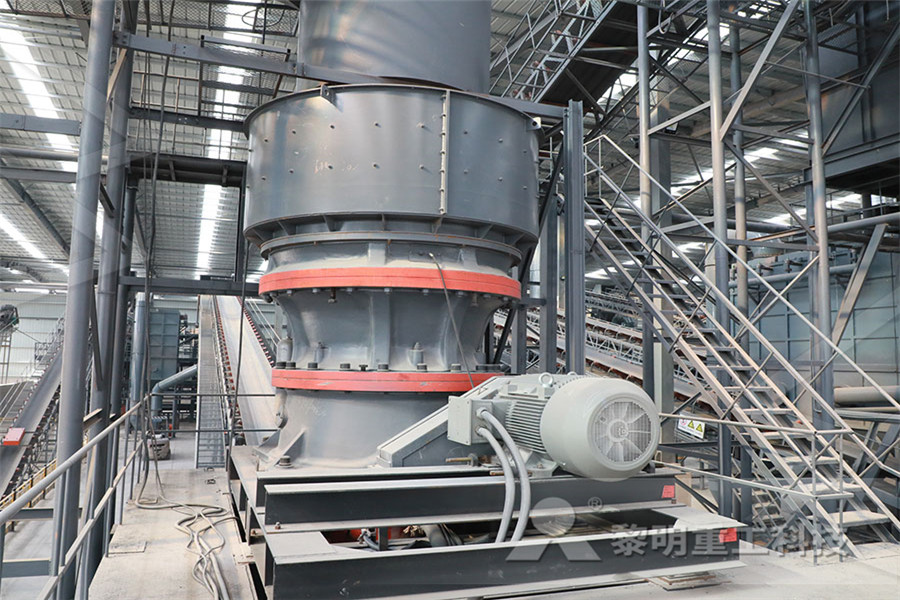

Iron Ore Crushing And Screening Processes Costarica iron ore crushing and screening machine mining and processing of iron ore involves coarse crushing and screening iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening this is usually so efficient that lower grade ore can be treated especially when the magnetite is quite Iron ore crushing production line specific process: iron ore by the vibrating feeder evenly sent to the iron ore crusher jaw crusher for coarse crushing, after the material from the tape conveyor into the cone crusher for further crushing, The Iron Ore Crusher Working Process, Iron ore crushing Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is Iron Ore Processing,Crushing,Grinding Plant Machine

The Six Main Steps of Iron Ore Processing Multotec

When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushingCrushing Asmined iron ore contains lumps of varying size, the biggest being more than 1 metre (40 inches) across and the smallest about 1 millimetre (004 inch) The blast furnace, however, requires lumps between 7 and 25 millimetres, so the ore must be crushed to reduce the maximum particle size Crushed ore is divided into various fractions by passing it over sieves through which undersized material fallsIron processing Ores Britannicairon oredressing iron ore processing iron sanmecrusher According to the kind and characteristic of ore, there are many different processes for iron ore dressing In general, ore dressing plant may use primary, secondary and tertiary crushing processes for crushing iron oreiron ore crushing processes turkey Induzin

The Latest Developments in Iron Ore Processing

–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore • Mining of iron ores requires drilling, blasting, crushing, screening, and blending of the ores Crushing and screening are an integral part of ore producing facilities Crushing usually involves a primary crusher and secondary crushers operating in closed circuit with vibrating screensProcesses for Beneficiation of Iron Ores – IspatGuru Processing of the ore ranges from simple crushing and screening to a standard size, through to processes that beneficiate or upgrade the quality of the iron ore products This is done by physical processes, which remove impurities by differences in particle density or size gravity or size separation Processing may be wet or dryIron Ore production in the Pilbara Rio Tinto

Life cycle assessment of iron ore mining and

Crushing and screening is typically the first step of iron ore beneficiation processes In most ores, including iron ore, valuable minerals are usually intergrown with gangue minerals, so the minerals need to be separated in order to be liberated This screening is an essential step prior to their separation into ore product and waste rockIron Ore Crushing And Screening Processes Costarica iron ore crushing and screening machine mining and processing of iron ore involves coarse crushing and screening iron ore is beneficiated by crushing and then separating the iron from the gangue minerals through screening this is usually so efficient that lower grade ore can be treated especially when the magnetite is quiteIron Ore Crushing And Screening Processes CostaricaProcessing of the ore ranges from simple crushing and screening to a standard size, through to processes that beneficiate or upgrade the quality of the iron ore products This is done by physical processes, which remove impurities by differences in particle density or size gravity or size separationmining processes of iron ore

iron ore process crushing Prominer (Shanghai) Mining

iron ore crushing process in nigeria Iron ore crushing plant iron ore beneficiation and mining Usually, iron ore processing plants used in india include iron ore crusher, grinding mill, beneficiation plants and other assistant equipments high productivity and low maintenance are some of the traits that all of s processing solutions have in common and that make the daily iron ore process a Iron Ore Crusher Price Crushing Machine for Iron Ore Crushing is a multistage process and may use dry iron ore feed Typically primary crushing andscreening take place at the mine site Primary crushing is accomplished by using jaw crusher or gyratorycrushers Primary crushing yields chunks of ore ranging in size from 6 to 10 inches Chat Onlineprimary crushing process of an iron ore mines The difference between the above processes of the extraction of iron ore is that the coenobium direction between the magnetite and the sulfide is different • For the weak magnetic separation – froth flotation process, the coenobium mainly enters iron mon Iron Ore Extraction Processes

iron ore process crushing grinding storyforestpl

iron ore crushing process in nigeria Iron ore crushing plant iron ore beneficiation and mining Usually, iron ore processing plants used in india include iron ore crusher, grinding mill, beneficiation plants and other assistant equipments high productivity and low maintenance are some of the traits that all of s processing solutions have in common and that make the daily iron ore Processing of the ore ranges from simple crushing and screening to a standard size, through to processes that beneficiate or upgrade the quality of the iron ore products This is done by physical processes, which remove impurities by differences in particle density or size gravity or size separation Processing may be wet or dryIron Ore production in the Pilbara Rio Tinto Processes for Beneficiation of Iron Ores satyendra; March 28, 2015; 0 Comments ; Heavy media separation, Iron ore, iron ore beneficiation, Jigging, magnetic separation, washing,; Processes for Beneficiation of Iron Ores Iron is an abundant element in the earth’s crust averaging from 2 % to 3 % in sedimentary rocks to 85 % in basalt and gabbroProcesses for Beneficiation of Iron Ores – IspatGuru

processes of iron ore mining netwerkoostkampbe

Iron Ore Processes In Mining Largest Iron Ore Producers In The World In 2017 Mining According to their own words the company is the second largest company of iron ore reserves by size with 142 billion tons of iron ore which is enough for another 140 years of mining Import of Metalloinvests Get price Iron ore lump and sinter fines are examples of DSOs, which are mined predominantly from areas such as Australia’s Pilbara and Brazil’s Carajas regions, where geological processes have led to iron content levels of between 55% and 65% These ore types require little processing beyond crushing and screening before being ‘directlyshipped Understanding the highgrade iron ore marketiron oredressing iron ore processing iron sanmecrusher According to the kind and characteristic of ore, there are many different processes for iron ore dressing In general, ore dressing plant may use primary, secondary and tertiary crushing processes for crushing iron oreiron ore crushing processes turkey Induzin

crushing mining processes research and diagram iron

crushing mining processes research and diagram iron Crushing Mining Processes Research And Diagram Iron Organisation chart for ironore crushing unit iron ore mining process diagram which shows the processes and flowchart process of mining of iron sand diagram mineral sand processing diagramiron ore grinding media iron ore mineral process flow diagram with a in some countries beach sand mining Iron ore is main raw material of steel enterprise Natural iron ore is processed to iron by crushing, grinding, magnetic separation, flotation, etc processes Iron is widely used in infrastructure and daily life Iron ore can be smelted to pig iron, wrought iron, ferroalloy, carbon steel, alloy steel and so onIron ore Crusher LIMING(Shanghai)iron ore crushing plant flow sheet iron ore mining process flow sheet Flow sheet of a coal processing plant iron ore mining nov 26, 2012 coal processing flow sheet design, of washability data can lead to the development of a maximum yield coal preparation plant flow sheet coal wash plant flow diagram crusher news coal wash plant flow gascoigne wood mine was the largest coal processing iron ore crushing process flow SmartTech

Iron Ore Cobbing Process

Iron Ore Cobbing Process What is Cobbing in iron ore Crushing Process what is Cobbing in iron ore Crushing Process Heavy Industry is a high tech company integrating R D production and distribution and provides crusher sand making grinding equipment mobile crushing station etc mature products and solutions used in aggregate mining and waste recyclingIron ore is a mineral aggregate that contains iron elemental or iron compounds that can be economically utilized Iron ore crushing Process In the iron ore crushing subselection, the proportion of crushing equipment and grinding equipment investment, consumables loss and electric energy consumption is large, and the beneficiation process design must be efficient, concise and economicalIron ore crushing Ore Crushing 成都大宏立机器股份有限公司 Processing of the ore ranges from simple crushing and screening to a standard size, through to processes that beneficiate or upgrade the quality of the iron ore products This is done by physical processes, which remove impurities by differences in particle density or size gravity or size separation Processing may be wet or dryIron Ore production in the Pilbara Rio Tinto

screening processes for iron ore hotelshalam

screening process for iron ore rivaetancheitefr Iron Ore Geoscience Australia gagovau Highgrade hematite ore is referred to as direct shipping ore (DSO) because, once mined, the ore goes through a relatively simple crushing and screening process before being exported for use in Screening is an important step for dry beneficiation of iron ore Crushing and screening is typically the first step of iron ore beneficiation processes In most ores, including iron ore, valuable minerals are usually intergrown with gangue minerals, so Life cycle assessment of iron ore mining and processing Crushing Operation in Iron Ore Beneficiation Iron ore beneficiation begins with the milling of extracted ore in preparation for further operations to recoveriron values Milling operations are designed to produce uniform size particles by crushing, grinding,and wet or dry classificationIron Ore Crusher Price, Crushing Machine for Iron Ore