The operating principle of the ball mill Primo Pizza

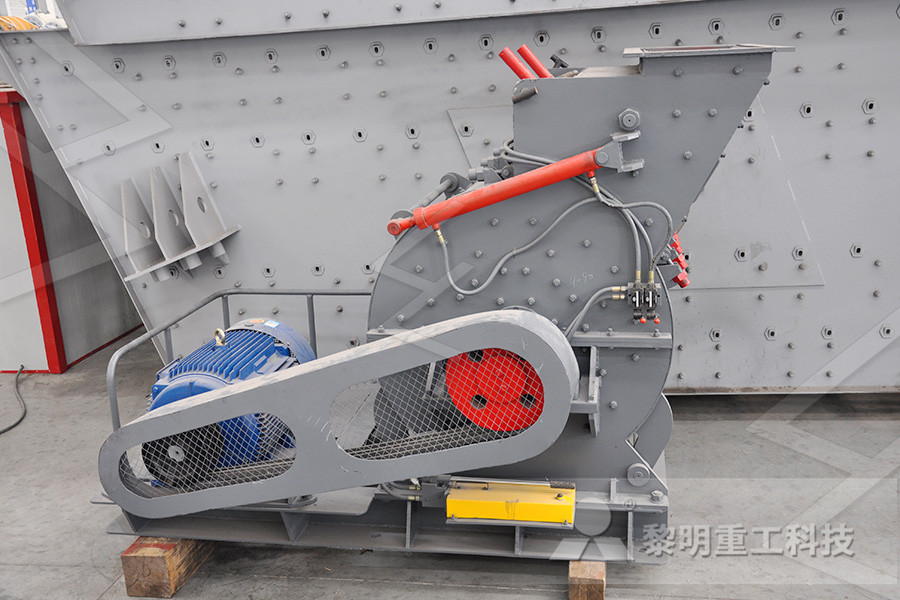

The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media When minimum fines are a requirement, the hammer mill should always he operated in closed circuit with a screen, or screens; the circulating load should be fairly high; speed should be as low as is consistent with physical structure of the material; Hammer Mill Operating Principle 911 Metallurgist Operating principle The operating principle of the mill is a rotor that is fitted with special tools It rotates at a high peripheral speed within a solid replaceable stator The mechanical design is conservative allowing the mill to operate safely under severe conditions and high peak loadingsOperating Principle The JäckeringGroup Core

Coal Mill Operating Principle mansampark

Pulverized coal mill operation principle mining Coal classifier principle coal processing system machine for sale the air mixes with and dries coal in the grinding zone and carries pulverized coal particles upward into a coal mill operationcoal mill working principle detailed coal grinding and drying in cement industryPiercer mill operating principle yesweschool Pendulum mill operating principle pendulum mill operating principle moviles comparador the principle It is uniformly heated in the rotary hearth heating furnace and then pierced by a Mannesmann piercer The pierced billet or hollow shell is rollreduced in outside diameter and wall thickness The rolled tube simultaneously burnished inside and Steel Pipe Manufacturing Processes mandrel mill Operating Principle, Performance and Applications of the Wave Mill 312 make estimations based on the size of the construction and measured power output Another reason is existing projects could not deliver the claimed output Often a real output was significantly less and therefore, did not contribute much to the landbased gridOperating Principle, Performance and Applications of the

Attrition mill operating characteristics ScienceDirect

The mill was then started and operated at a predetermined rotor velocity for a measured time period The entire solid contents of the mill were then removed, and the coarse medium particles were separated from the millable particles by screening The principle involves a variable force rotate blades having both knife and sharp edges with validated screen size to reduce particle in a controlled manner The mechanism envolve pulverization process ( pulverization is grinding and crushing of materials into small particles) knife is used to cut the large particles into small size particle, these big particles are made from granules during the drying Multimill; working and principle in Pharmaceutical Pin mill work by similar principle as hammer mills (impacts and shearing) but with typically faster tip speed rotorstator configuration of intermeshing pins which impact the particles as solids are directed through the intermesh pins The mill product leaves Pin Mill: Description, operating principles, advantages

The Incompleteness of the Harm Principle MIT

In contrast, a principle of parity works as well for large and fractured societies as it does for smaller and coherent ones, by making that question irrelevant Score one for MillCoal Mill Operating Principle Pulverized coal mill operation principle mining Coal classifier principle coal processing system machine for sale the air mixes with and dries coal in the grinding zone and carries pulverized coal particles upward into a coal mill operationcoal mill working principle detailed coal grinding and drying in cement industryPiercer mill operating principle Coal Mill Operating Principle mansamparkMandrel Mill Process In the Mandrel Mill pipe manufacturing process, the steel billet is heated to high temperature in the rotary furnace A cylindrical hollow, which is also known as mother hollow, is produced with the help of a rotary piercer and set of roller arrangement that the operating principle of the ball mill ball mill operation procedure Escort

Steel Pipe Manufacturing Processes mandrel mill

In the Mandrel Mill Process, a solid round (billet) is used It is heated in a rotary hearth heating furnace and then pierced by a piercer The pierced billet or hollow shell is rolled by a mandrel mill to reduce the outside diameter and wall thickness which forms a multiple length mother tube when the machine is operating Chips should be removed from the workpiece with an appropriate rake and a brush NOTE Chip rake should be fabricated to the size of the Tslots (Figure 82) Shut the machine off before making any adjustments or measurements When using cutting oil, prevent splashing by using appropriate splash guardsMILLING OPERATIONS TYPES OF MILLING MACHINESOver the spectrum of starting billet diameters and lengths for Typical Rolling Schedule II, shell length after elongation in the Diescher mill may range from about 6776 feet to about 9484 feet, with corresponding substantial reduction in wall thickness from the No 2 piercer In the sizing mill, further elongation may range from about 109 to Seamless tube mill AetnaStandard Engineering

Tubular Products Jubail ArcelorMittal

The tube making process begins with the crossroll piercer transforming the red hot billet into a hollowpassing next into the multi stand PQF® mill a process based on the mandrel principle and containing a series of hydraulically adjustable 3roll The Kocks Rotation Mill – KRM – is an innovative elongation method for seamless tube production in diameters up to 45’’ (1143mm) at production levels up to 150,000 tpy Using the principle of planetary cross roll elongation, the machine rotates four rolls around the work piece A retained mandrel is used to set the wall thickness to aKOCKS ROTATION MILL [KRM] – AN INNOVATIVE The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the ballsconstruction of ball tube mills Salzgrotte Stein

roller mill xinmas overbroeckstablesbe

Crown Roller Mill Office Building Location 105 5th Avenue S Minneapolis MN Located on the Mississippi River, with the Stone Arch Bridge and the downtown Minneapolis Mill District at our doorstep, the Crown Roller Mill is the perfect setting for doing creative and inspiring workThe manufacturing facility consists of a rotary hearth furnace, a conetype rotary piercer and a multistand pipe mill In addition it has a 22stand stretch reducer followed by straightening, cutting and beveling facilities, as well as an Electromagnetic, ultrasonic and hydrostatic testing unitsMammba Metal Group Pty td Posts FacebookPiercer Mill Operating Principle As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for anyel sizereduction requirements including quarry, aggregate, and different kinds of mineralsPiercer Mill Operating Principle zckatwijk,piercer mill operating principle piercer mill operating principle get price and support simply Piercer Mill Operating Principle arbeitsrechtnowakde

Tubular Products Jubail ArcelorMittal

The tube making process begins with the crossroll piercer transforming the red hot billet into a hollowpassing next into the multi stand PQF® mill a process based on the mandrel principle and containing a series of hydraulically adjustable 3roll WORKING PRINCIPLE The motor drives the grinding table through decelerator The materials fall down the center of grinding table from feed opening At the same time hot air comes into the mill from the air inlet Due to the centrifugal force materials move to the edge of the grinding tableworking principal of vartical raw mill in zimbabweThe operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the ballsconstruction of ball tube mills Salzgrotte Stein

A review of the longitudinal rolling of tube on two

He quotes for a tworoll tube rolling mill operating without interstand tension, ie sinking, a constant effective roll radius of approximately 91 per cent of the pass height and suggested that this value could also be used for the threeroll system However for tube reducing mills employing interstand tension this radius could change appreciably1 127 (canceled) 28 A method of making a seamless hotfinished steel pipe, comprising the steps of: piercing a billet, which has been heated to a shaping temperature, in a first shaping step to produce a thickwalled hollow ingot; and subjecting the hollow ingot to a radial forging process in a second shaping step for elongating the hollow ingot at the shaping temperature to change the METHOD OF MAKING A SEAMLESS HOTFINISHED Crown Roller Mill Office Building Location 105 5th Avenue S Minneapolis MN Located on the Mississippi River, with the Stone Arch Bridge and the downtown Minneapolis Mill District at our doorstep, the Crown Roller Mill is the perfect setting for doing creative and inspiring workroller mill xinmas overbroeckstablesbe

Aufbau und Wirkungsweise EnglischÜbersetzung –

operating principle n The cross roll piercing mill type also known as a barrel piercer (Fig 8) used in [] the plug mill differs [] considerably in design and function from the cross roll piercing mill used in conjunction with pilger mills runner principle and, apart from a 2020/08/25Mandrel Mill Process In the Mandrel Mill pipe manufacturing process, the steel billet is heated to high temperature in the rotary furnace A cylindrical hollow, which is also known as mother hollow, is produced with the help of a rotary piercer and set of roller arrangement that keeps the piercer at the center of the billet Get pricelw mill h beam specampsize list netwerkoostkampbeBEAD PIERCER Employed to drill the holes in beads BEADLE or BEDEL or BEDELL Officer of the parish whose principle duty was to keep order Was also the town crier BEADMAN or BEADSMAN or BEDESMAN Employed to pray for his employer, inhabitant of an almshouse / poorhouse or hospital or tenant employed by the manor for a specific serviceList of Old English Occupations and descriptions