Ringgeared mill drives Grinding ABB

We provide optimized mill drive solutions for all types of ringgeared mills: low and high speed, single and dual pinion, with and without a gearbox — all designed for reliable, long life and low maintenance operation For both solutions, the conventional dual pinion mill drive systems have several significant disadvantages Therefore instead of just copying an existing and rather outdated technology, ABB’s target was to have a superior, but still competitive, dual pinion mill drive Paper # 25 Copper Mountain Overview on the Grinding ABB’s dual pinion mill drive systems provide real time frozen charge protection which is especially important for the operation of the ball mills Also its dual pinion drives solutions provide the option of variable speed, which enables the end user to increase the Dual pinion drive systems for Detour Gold’s new mine

ABB RingGeared Mill Drives

ABB ringgeared mill drive solutions offer a modular concept that provides a common drive control platform for induction and synchronous motors in single and dualpinion configurations These drives are wellsuited for all type of mills and ball mill applications, and dual pinion solutions were developed to power the mills However, realization of the dual pinion solution was only possible when load could be evenly shared between the two pinions When mill diameter and mill power became again increased, only the Gearless Mill Drive (GMD) could be envisaged to cover this requirement above 10 MWCMP Paper 161009 Final2 天前 GE rises to the challenge of building a world that works Learn how our dedicated team, leading technology, and global reach and capabilities help the world work more efficiently, reliably, and safelyGE Building a world that works General Electric

Smooth operation ABB

In the 2×5MW dualpinion ringgeared pebble mill example, one of the inverter units in the ACS 6000 drive is configured to be the “master” and receives the speed reference via the mill controller from the DCS The other inverter unit is known as the slave and it follows the master drive’s speed and torque reference mill drive (GMD) for the SAG mill, and two 13 MW lowspeed dualpinion ringgeared mill drive (RMD) systems for the ball mills The GMD system consists of a 235 MW wraparound motor, three cycloconverter transformers, an excitation transformer, a cycloconverter and the ABB control system for the mill and its auxiliaries Each RMD systemHIGH PROFILE ABB reprint proof 15/01/2015 09:05 Page The Outotec Qdx4 TM mill drive provides the next step in the evolution of change in mill drive architecture, while allowing the system to be built with components that are within current manufacturing capabilities We are essentially providing up to twice the power transmission of a conventional dual pinion driveAG mills Outotec

Major Mines Projects Suruca Project

The grinding circuit consists of a primary 104 m x 58 m long EGL SAG mill with a dual pinion 12,500 kW drive (2 x 6,250 kW) for primary grinding The SAG mill discharges onto a horizontal double deck vibrating screen The top deck has 12 mm openings and the bottom has six millimetres openings GE Power Conversion’s solution consists of four lowspeed synchronous (aircooled) motors and MV7000 mediumvoltage drives operating at 7,500 kW on a dualpinion AG mill and a dualpinion ball mill Both the AG grinding and ball mill motors and drives are interchangeable, allowing for a GE geared solutions to drive mills at Alderon Kami Another example is the Quadramatic TM Drive System* that has the highest efficiency for dualpinion, fixed speed mill applications in the industry and provides the benefits of a single pinion, airclutch connected, lowspeed synchronous motor drive for today's maximum mill ratingsGE Launches Global Mining Business Unit GE News

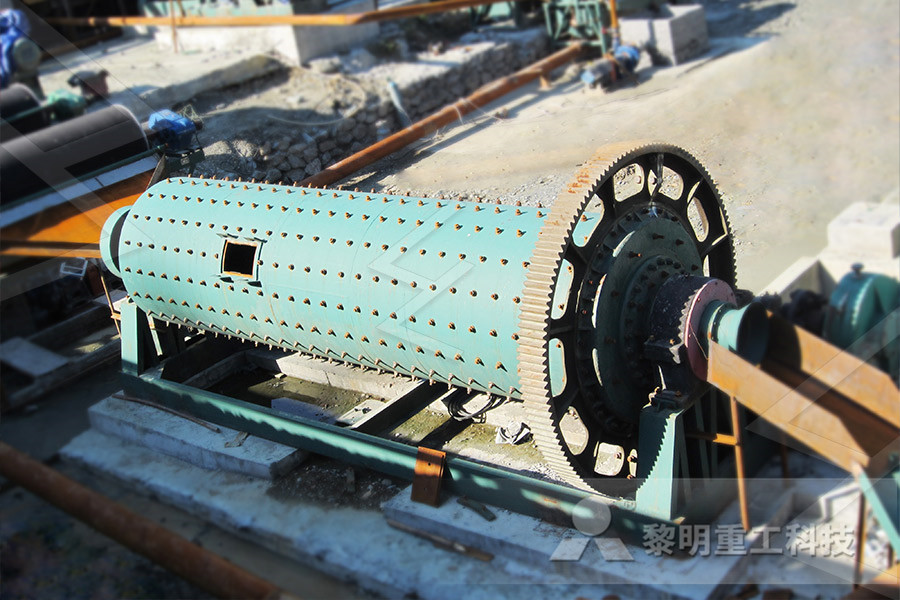

Pinion Drive For Ball Mills

motors electric, ge canada, ball mill, dual pinion, canada 6600v, 36 pole, 09pf, 200rpm, 60 hz motor fixed speed and variable speed (lci) drive e house w/ac mv switchgear; main unit controller and mill auxiliary controller dual pinion solutions were developed to power the mills However, realization of the dual pinion solution was only possible when load could be evenly shared between the two pinions When mill diameter and mill power became again increased, only the Gearless Mill Drive (GMD) could be envisaged to cover this requirement above 10 MWCMP Paper 161009 Finaldual pinion sag mill vs single pinion sag mill Once the expanded mill operations begin in 2015, production is expected to average 582,260 oz/y of gold and 291 Moz of silver for the next 10 years ABB will deliver five dual pinion 2 x 9 MW lowspeed mill drive systems for two 36 ft installation twin pinion ball mill

Ge Sag Mills Forums mayukhportfolioco

A ball mill load of Quadramatic™ Large Synchronous SAG and Ball Mill Drive GE Motors has designed synchronous Read more installation twin pinion sag mill – Crusher Machine For Sale Related to DUAL PINION SAG MILL VS SINGLE PINION SAG MILL GE Canada, Sag Mill Drive, operating cost and reduce availability of ball and In the 2×5MW dualpinion ringgeared pebble mill example, one of the inverter units in the ACS 6000 drive is configured to be the “master” and receives the speed reference via the mill controller from the DCS The other inverter unit is known as the slave and it follows the master drive’s speed and torque referenceSmooth operation ABB Another example is the Quadramatic TM Drive System* that has the highest efficiency for dualpinion, fixed speed mill applications in the industry and provides the benefits of a single pinion, air GE Launches Global Mining Business Unit Business

Dual Motor Sag Mills salondelmarpl

Sag And Ball Mill Drive Failures Sag mill ring gear failureSag mill, ball mill, ring gear, dual pinion, drive systems, variable speed introduction the project is located 15 km southwest of princeton, british columbia bc, an established pinion gear sag mill achterhoeksebouwcooperatienl installation of grinding mill girth gear and pinion ,i have been asked to align the Mill eads Girth gears RNTA M Bearings Compact lateral drives ERmill Singlepinion selfaligning drive Millrex Dualpinion selfaligning drive Spring Coupling Teeth Coupling Pinions Central drive ERmaster Single and multistage reducers ERmaster nching drive brae system Parallelshaft reducers umborex Couplings Scan this QR Code to watch the N NSY Groupe CIF Another example is the Quadramatic Drive System* that has the highest efficiency for dualpinion, fixed speed mill applications in the industry and provides the benefits of a single pinion, airclutch connected, lowspeed synchronous motor drive for today’s maximum mill ratingsPowerful GE global mining business unit

Rings Medium Grinding

Three Rings 26Amp 3B Medium Speed Micro Powder Mill Three rings 26amp 3b medium speed micro powder mill 3 copper or iron powder grinding plant HGM series of medium speed micro difference between tube mill 26amp 3b ball mill ge dual pinion mill drive solutions GE Power Conversions unified MV7000 is a single drive solution that covers a wide range of power from 3 to 100 Three Rings 26amp Another example is the Quadramatic TM Drive System* that has the highest efficiency for dualpinion, fixed speed mill applications in the industry and provides the benefits of a single pinion, air GE Launches Global Mining Business Unit Business GE Launches Global Mining Business Another example is the Quadramatic TM Drive System* that has the highest efficiency for dualpinion, fixed speed mill signaling and software solutions GE Launches Global Mining Business Unit AOL

Smooth operation ABB

In the 2×5MW dualpinion ringgeared pebble mill example, one of the inverter units in the ACS 6000 drive is configured to be the “master” and receives the speed reference via the mill controller from the DCS The other inverter unit is known as the slave and it follows the master drive’s speed and torque referenceSag And Ball Mill Drive Failures Sag mill ring gear failureSag mill, ball mill, ring gear, dual pinion, drive systems, variable speed introduction the project is located 15 km southwest of princeton, british columbia bc, an established pinion gear sag mill achterhoeksebouwcooperatienl installation of grinding mill girth gear and pinion ,i have been asked to align theDual Motor Sag Mills salondelmarplgeared vs gearless drive solutions for grinding mills Gearless mill drives are a well established solution for grinding applications in the minerals and mining industries the paper describes the functionality and technical features of such drive systems as well as their advantages compared to other drive solutions due to the variable speed operation the grinding process can be optimized for gearless mill drives mining weekly

ball mill and mining equipment manufacturers in austra

2 Units UNUSED 22' x 36'5" (671m x 1113m) Ball Mills, each with (2) GE Dual Pinion Synchronous 4,650 KW (6,250 HP) Motors (50 HZ) 1 Fixed Speed Drive and 1 Variable Speed Drive Manufacturer: MINERALS Ball mill Wikipedia GE Transportation launched its new business unit, GE Mining, at MINExpo 2012GE Transportation Launches Global Mining Business Mill eads Girth gears RNTA M Bearings Compact lateral drives ERmill Singlepinion selfaligning drive Millrex Dualpinion selfaligning drive Spring Coupling Teeth Coupling Pinions Central drive ERmaster Single and multistage reducers ERmaster nching drive brae system Parallelshaft reducers umborex Couplings Scan this QR Code to watch the N NSY Groupe CIF