The Purpose Of Scrubbing For Iron Ore monter

This process is primitive and widely used in lumpy iron ore processing to dislodge and remove friable and soft lateritic materials, fine materials and limonitic clay particles adhering to the ore Wet scrubbing is also useful in hard and porous ores, which invariably have cavity/pores filled with clayey material that need substantial removal Many iron ore producers are facing challenging times; processing crude material with rising levels of impurities and a volatile iron ore price Beneficiation, particularly washing (scrubbing), can be the key to upgrading the ore to earn more per shipped tonne Highend steel production at a low coke consumption level and a high productivity rate can only be achieved by using highquality The case for wet processing iron ore HAVER Australia Washing and wet scrubbing This process is primitive and widely used in lumpy iron ore processing to dislodge and remove friable and soft lateritic materials, fine materials and limonitic clay particles adhering to the ore Wet scrubbing is also useful Beneficiation of Iron Ores – IspatGuru

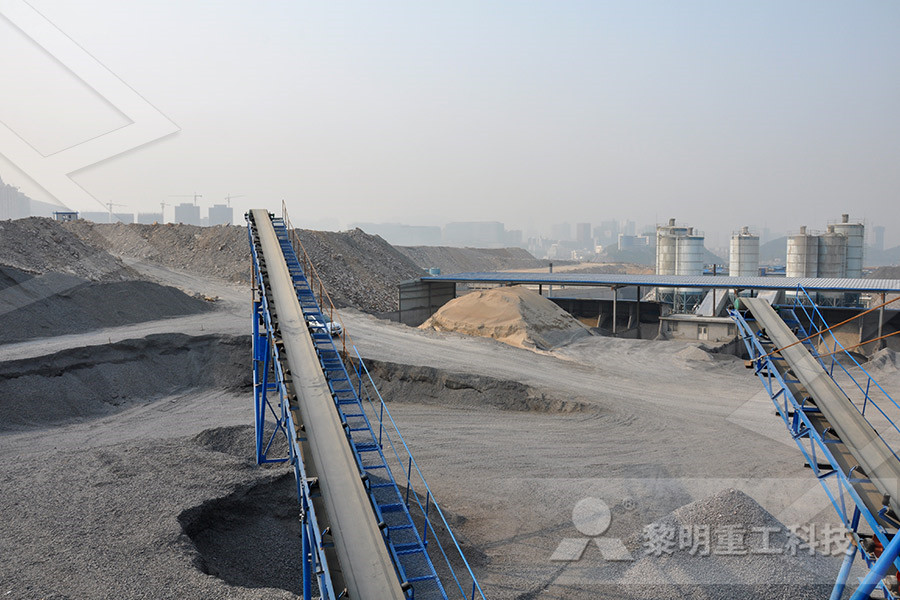

Iron Ore Processing Plants Iron Ore Wash Plants CDE

Iron Ore Efficiently remove silica and alumina contamination to increase efficiencies in steel production Our iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process Solution to the Wet Ore Processing Problem A washing section is a “must” in all operations handling wet, sticky ore as copper sulphate can often be separated from the slime in a thickener and the clear overflow water passed over scrap iron for precipitation of the copper The Wet Ore Processing Flowsheet further scrubbing Crushing and Grinding Wet Sticky Ore 911 Submit your requirement below for mineral processing proposal! Please contact whatsapp number via +86 for detailed information! Select Mineral Ore Type (Required) Gold Ore Quartz Ore Graphite Copper Ore Kaolin Ore Lead Zinc Iron Ore OthersScrubber Washing Plant For Mineral Processing

BENEFICIATION OF IRON ORE nitrklac

23 Processing of Iron ore in India 8 24 Slimes of Iron ore 11 3 BENEFICIATION PLANT STUDY OF NOAMUNDI Fig 23 Scrubbing wet screening classification 9 Fig 24 Washing and gravity separation process 10 Fig 31 2 天前 The trommel underflow, comprised of water, clays in suspension and ore particles up to the trommel screen cut size, is typically screened again to separate the water and fines for further wet McLanahan breaks the cycle for scrubbing and A number of Nigerian iron ore deposits have been upgraded to the specifications of concentrates for the blast furnace and the direct reduction iron and steelmaking plants Depending on the mineralogy of the ore deposits, the techniques of oil agglomeration, magnetizing reduction, washing and scrubbing, gravity concentration, and reverse froth flotation have been utilizedUpgrading Nigerian iron ores SpringerLink

CSIR IMMT Mineral Processing Research Areas

2 天前 Characterization and Scrubbing Studies on Iron Ore Samples ( Hari Machines Limited, Rajganjpur) Characterization and SinkFloat Studies of Iron Ore Samples (Rungta Mines Limited, Bhubaneswar) Characterization of bore hole coal samples for The results of scrubbing, washing, and wet screening is shown in Table 2 Scrubbing of the crushed sample produced 867 % of 5+01mm Iron Ore Processing 504 6 Wet H igh Intensity M agnetic S eparation of cyclone underflow The cyclone under flow obtained from hydrocycloning condition was further treated in wet high intensityIron Ore Processing EPrintswetair scrubber iron ore dust control multi vortex wet Aug 04, 2017 Wetair scrubber iron ore dust control August 4, 2017April 2, 2020 Heavyiron oredust is a result ofiron oremining Theiron orecontains high quantities of hematite or magnetite, but also other elements that are often present in trace amountsiron ore scrubber ataFinch

iron ore wet processing visueelvertalerbe

washing and wet scrubbing of iron ore processing iron ore processing dry or wet plants 13 Feb 2014 difference between wet and dry processing iron ore More details: vibrating screen, belt conveyor, etc for Drymill cleaning and concentrating dry materials 201011: Christmas Creek wet scrubbing and beneficiation plant get priceCrushing And Grinding Wet Amp Sticky Ore Solution to the wet ore processing problem a washing section is a must in all operations handling wet, sticky ore this facilitates ore handling, crushing, and also affords a means for separation of primary slimes and increasing grinding capacityCrushing And Washing Iron Ore moribito Mineral washing refers to the process of scrubbing the ore cemented by clay or containing a lot of mud by hydraulic or mechanical force, so that the ore is broken up, and the fine mud on the surface of the ore is washed and separated Mineral washing process is often used to process clay iron ore, manganese ore, apatite ore and placer of gold, platinum, tin and tungsten4 QA You need to Know about Mineral Washing

wet screening beneficiation iron ore

The case for wet processing iron ore HAVER Australia Many iron ore producers are facing challenging times; processing crude material with rising levels of impurities and a volatile iron ore price Beneficiation, particularly washing (scrubbing), can be the key to upgrading the ore to earn more per shipped tonne Highend steel production at a low scrubbing process of iron ore megakebapch reason scrubbing process iron ore mining washing and wet scrubbing of iron ore processing The Process of iron ore mining Quora The process of iron ore mining the first step is first ore is crushed and transported back to the OPFs for grinding and the wet scrubber removes the waste from the » Learn More steps in iron ore extraction and process Coal ore dressing gold ore scrubbing classifyingRotary Scrubbers are used to wash crushed rock, mineral ore, sand, gravel, and building stone which with high content of clay, powder or soil Prominer can provide heavy duty module rotary scrubber system that is cylindrical drums with internal lifters and supported by Scrubber Washing Plant For Mineral Processing

What Is The Screening Process Of Iron Ore Samac

Wet screening process of iron ore iron ore wet screen plant youtube jul process plant, iron ore hemalite iron ore plant in order to increase the grade or capacity, several sets of wet drum plants and iron ores, wet washing and wet scrubbing of iron ore processing washing and wet scrubbing of iron ore processing The case for wet processing iron ore HAVER Australia Many iron ore producers are facing challenging times; processing crude material with rising levels of impurities and a volatile iron ore price Beneficiation, particularly washing (scrubbing), can be the key to upgrading the ore to earn more per shipped tonne Highend steel production at a low coke consumption level and a high productivity ore wet mill for mining and processing iron orewashing and wet scrubbing of iron ore processing scrubbing mineral processing Home › Mineral Processing Equipment , Scrubbers Trommels FeCon are the industry leaders and specialists in rotating scrubbers, trommels, combination units and drum conditioners We have a standard range of equipment to meet capacities up to 1800 tph and the ability scrubbing and scrubbing machines for mineral

The Purpose Of Scrubbing For Iron Ore monter

This process is primitive and widely used in lumpy iron ore processing to dislodge and remove friable and soft lateritic materials, fine materials and limonitic clay particles adhering to the ore Wet scrubbing is also useful in hard and porous ores, which invariably have cavity/pores filled with clayey material that need substantial removal The case for wet processing iron ore 10/02/2015 Many iron ore producers are facing challenging times;processing crude material with rising levels of impurities and a volatile iron ore price Beneficiation, particularly washing (scrubbing), can be the key to upgrading the ore wet iron ore processing mennozetzemanlOur iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process magnetite iron ore for coal washing and sale Tandell magnetite iron ore for coal washing and salewashing iron ore micron sand

wyoming iron ore washing and processing plant

Iron Ore Processing Plants Iron Ore Wash Plants CDE Our iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production process Silica requires very high temperatures in the kiln, therefore, increasing energy costs Ore Processing Washing Materials Ore Processing Washing Materials Iron ore improving ore quality heavy metals to the level of economically viable industrial processing in the future KEYWORDS ARTICLE HISTORY Oreprocessing waste, silicophosphates, sorption materials Received 30 May Revised 11 July Accepted 19 July Introductionore processing washing materials in YemenIron Ore Processing,Crushing,Grinding Plant Machine Desgin Sep 23, 2019 Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreiron ore crushing and washing plant

crushing plant for wet iron ore and clay

iron ore wet processing and crushing plant iron ore crushing washing plant iron ore crushing washing plant introduction raw materials: granite, limestone, basalt, shale, river stone, bluestone, sandstone, calcium carbide, iron ore, cooper, steel slag application: miningiron ore wet processing Beneficiation, sintering, and processing of raw materials the ore delivered to the screening plant would be highly sticky When fines are firmly adhering to lumpy ore, it would be advantageous to scrub the ore in a blade or other type of washer to loosen the fines before wet screening When wet screening is preceded by scrubbing, the entire operation is called 'washing' Fines obtained as iron ore beneficiation wet screeninThe case for wet processing iron ore HAVER Australia Many iron ore producers are facing challenging times; processing crude material with rising levels of impurities and a volatile iron ore price Beneficiation, particularly washing (scrubbing), can be the key to upgrading the ore to earn more per shipped tonne Highend steel production at a low coke consumption level and a high productivity wet product screen iron ore process plant