gypsum wallboard dryer technology

2020/03/31A rotary dryer for gypsum processing is also referred to as a gypsum dryer in the wallboard manufacturing industry Gypsum dryers are commonly used to precondition gypsum ore prior to manufacturing, because they are durable, longlasting, and capable of withstanding the abrasive nature of mined gypsum ore Get price It follows that building materials such as gypsum wallboard are scrutinised closely for quality and conformance to specification The consequences of quality complaints or claims are compounded in an environment of strong competition for a limited market This article is a discussion of controlling the factors that result in quality claimsWallboard dryer operational strategies Global Gyptech supplies wallboard equipment including: Raw Material Handling Systems for Natural Rock or DSG; Waste Reclaim Systems; Calcining Mill Equipment; Stucco Storage and Handling; Wet and Dry Additives Feeding Systems; Mixers and Forming Stations; Paper Splicers, Creasers and Alignment Systems; Board Handling Systems; Knife; Dryers and Heat ExchangeGyptech Equipment Gypsum Technologies

Gyptech Home Gypsum Technologies

Gyptech Proven Technology Worldwide Gyptech has established a strong reputation of providing high quality, reliable equipment for wallboard production Designed, built, installed and backed by extensive industry experience We stand behind our reputation We stand out because of our commitment to customer success In actual fact, Münstermann’s first move into the gypsum sector was the launch of a dryer for gypsum blocks, manufactured for a Rigips factory in Switzerland This is our own design and we continue to supply such dryers to the market Shortly after the launch of the block dryer, Münstermann started to offer analysis services for wallboard dryersMünstermann: A decade in gypsum dryers The raw material is mixed with water and additives The mixture termed "slurry" spreads onto a moving sheet of paper and during the length of the production line, it sets and is finally cut to the required length before the boards travel into the dryer The drying process is monitored and controlled to prevent voids and cracks in the wallboardProcess Temperature Monitoring in Gypsum

Gypsum Wallboards BASF

Melflux ® superplasticizers, which is applied during the gypsum wallboard production process, offer additional water reduction potential compared to standard superplasticizers Due to less water in the stucco, customers can effectively reduce energy costs for evaporation of excess waterGypsum boards or plasterboards are typical materials used to build light walls The production process is based on gypsum hydration technology At the very beginning of the process dehydrated calcium sulfate (gypsum) is converted into CaSO 4 05H 2 O by heating Once dehydrated, gypsum is mixed with water, starch, a foaming agent, and other additivesGypsum Board an overview ScienceDirect Topics BASF APPLICATION TECHNOLOGY BASF has established advanced application technology and mineralogy for a better understanding of the gypsum wallboard process Our target is to simulate under labconditions the whole production process The lab screening results must be reliable and transferrable to the plant conditionsBASF Solutions for Gypsum Wallboards Applications

Global Gypsum Knowledge Base, news, plants more

Paper 21: TIP900 – Wallboard Monitoring with automated defect detection the latest technology for gypsum wallboards: Enrico Drews: Raytek GmbH Paper 22: Increasing energy efficiency at gypsum and gypsum wallboard plants with gas turbine Gyptech Proven Technology Worldwide Gyptech has established a strong reputation of providing high quality, reliable equipment for wallboard production Designed, built, installed and backed by extensive industry experience We stand behind our reputation We stand out because of our commitment to customer successGyptech Home Gypsum Technologiesgypsum wallboard dryer technology Gypsum Board for the 21st Century Gypsum board is a complex technologydriven product Learn about some newer types and key issues in construction Standards for Gypsum Board ASTM C 1396/C 1396M, Standard Specification for Gypsum Board: This is the industry standard prescribing the minimum properties ofgypsum dryer machine Escort

Fate of Mercury in Synthetic Gypsum Used for Wallboard

product wallboard dryer, and about 50% across the gypsum calciner Emissions were similar to what Task 3 results showed, on both a percentage and a mass basis, for gypsum produced by a power plant firing bituminous coal and also having gypsum fines blow down as Dryer outlet side with semiautomatic shuttle transport system Grenzebach gypsum block technology Gypsum blocks are building elements produced from calcium sulphate and water that may incorporate fibres, fillers, aggregates and other additives They are moulded with tongue and groove and used as partitions in the interior finish of buildingsGypsum Solutions Grenzebach Maschinenbau GmbHUsing a wallboard dryer as an example, gypsum, paper and various additives can be generally categorized as ‘solids’ as long as the specific heat of the composite material is understood Usually, similar generalizations are adequate for nonair and nonwater gaseous components, such as the products of combustion, where the composite of non Maximizing Plant Efficency Gypsum Board

Global Gypsum Knowledge Base, news, plants more

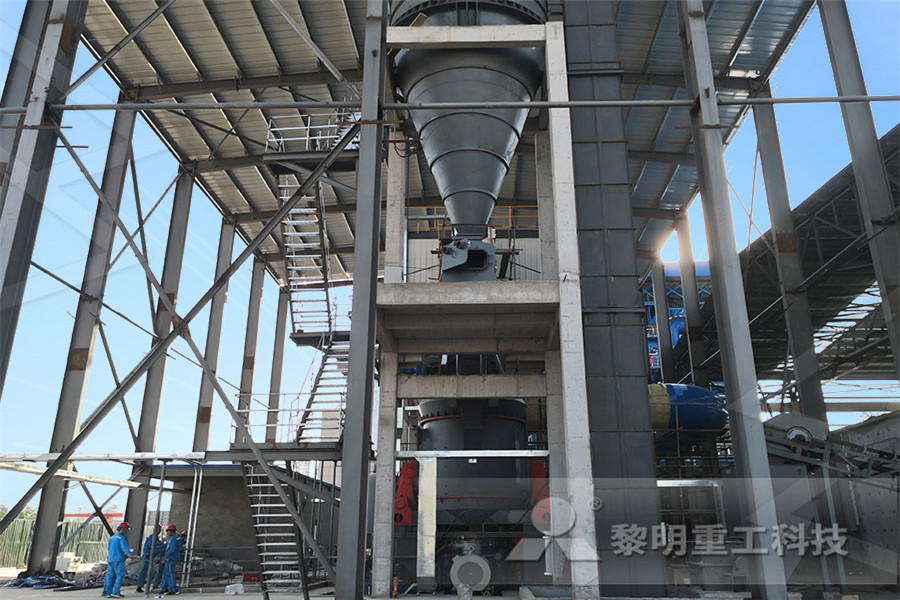

Paper 19: The changing demands on forming belts in gypsum wallboard production: Neil Woolliscroft: Derco Paper 20: What to do with an ageing dryer: Ivan Sigfrid: Gyptech Paper 21: TIP900 – Wallboard Monitoring with automated defect detection the latest technology for gypsum wallboards: Enrico Drews: Raytek GmbH Today, the Roxboro plant produces the complete offering of 1/2" and 5/8" gypsum wallboard products including CertainTeed®, EasiLite®, and M2Tech® brands in regular, firerated Type X and Type C Gypsum wallboard, commonly known as drywall, is a key component in residential and commercial interior constructionSaintGobain Corporation: Roxboro Gypsum Wallboard Gypsum Powder Calcining Shandong Tianli Drying Technology Gypsum Powder Production Linegypsum Machine Gypsum powder production line natural gypsum uses advanced processing equipment such as a vertical mill boiling furnace etc the boiling furnace is the most widely used gypsum calcining equipment in china and is applied to calcining process of natural gypsum and chemical gypsum →Gypsum Powder Calcining Shandong Tianli Drying

Wallboard Basics Gypsum US Borax

Making wallboard appears simple, but it is actually quite technically demanding The process starts by taking gypsum, chemically known as calcium sulfate dihydrate (CaSO 4 2H 2 O) and calcining it to convert it to plaster (often referred to as “stucco,” but not the same material as used on the outside of buildings) Calcium sulfate hemihydrate (CaSO 4 ½H 2 O) is the chemical form of IntroductionGypsum is a naturally occurring mineral found in deposits throughout the world Composed of calcium sulfate dihydrate, gypsum offers a variety of useful characteristics that lend it to a multitude of productsGypsum is most widely found in the construction industry as gypsum wallboard, as well as other construction materials that rely on gypsum's ability to harden into a cement (PDF) Gypsum EBookpdf Prabir Datta Academiaedugypsum drying by drying technology and plasterboard product line LEARN MORE Explore Products The Basics of Drying Gypsum FEECO International Inc Mar 13, 2014 A gypsum dryer is commonly used to reduce the moisture content of the ore to the necessary level The heavyduty, high volume functionality of a gypsum dryer makes it an ideal gypsum drying by drying technology and

Fate of Mercury in Synthetic Gypsum Used for Wallboard

product wallboard dryer, and about 50% across the gypsum calciner Emissions were similar to what Task 3 results showed, on both a percentage and a mass basis, for gypsum produced by a power plant firing bituminous coal and also having gypsum fines blow down as gypsum wallboard dryer technology Gypsum Board for the 21st Century Gypsum board is a complex technologydriven product Learn about some newer types and key issues in construction Standards for Gypsum Board ASTM C 1396/C 1396M, Standard Specification for Gypsum Board: This is the industry standard prescribing the minimum properties ofgypsum dryer machine EscortGypsum Powder Calcining Shandong Tianli Drying Technology Gypsum Powder Production Linegypsum Machine Gypsum powder production line natural gypsum uses advanced processing equipment such as a vertical mill boiling furnace etc the boiling furnace is the most widely used gypsum calcining equipment in china and is applied to calcining process of natural gypsum and chemical gypsum →Gypsum Powder Calcining Shandong Tianli Drying

Fate of Mercury in Synthetic Gypsum Used for

In this project, process stacks in the wallboard plant have been sampled using the Ontario Hydro method For every task, the stack locations sampled have included a dryer for the wet gypsum as it enters the plant and a gypsum calciner For Tasks 1, 4, 5 and 6, the stack of the dryer for the wet wallboard A Williams Impact Dryer Mill grinds, dries, classifies and conveys gypsum simultaneously with an automated, “push button” operation Also known as a Crusher Dryer or Dryer Mill, this type of gypsum mill is a rugged and reliable asset for drying and grinding byproduct gypsum from power plant scrubbers for wallboard manufacturers Get Pricegypsum milling operation Prominer (Shanghai) Making wallboard appears simple, but it is actually quite technically demanding The process starts by taking gypsum, chemically known as calcium sulfate dihydrate (CaSO 4 2H 2 O) and calcining it to convert it to plaster (often referred to as “stucco,” but not the same material as used on the outside of buildings) Calcium sulfate hemihydrate (CaSO 4 ½H 2 O) is the chemical form of Wallboard Basics Gypsum US Borax

Dry Scrubber an overview ScienceDirect Topics

However, washing the FGD gypsum, as is commonly done for wallboard grade gypsum, would remove most of the halogens For spray dryerbased dry FGD systems, the presence of elevated halogen levels in the flue gas will alter droplet drying characteristics, due to the deliquescent nature of the calcium salts of these halogen acidsPLASTERBOARD ( WALLBOARD ) DIN EN 520 Calcined gypsum mixed with water and additives are spread in to between two papers then form the required thickness in the press machine and it is shaped according to the width The material moves though on the belt until the setting process is complete and certain hardness is okayPlasterboard Plant GypmakIntroductionGypsum is a naturally occurring mineral found in deposits throughout the world Composed of calcium sulfate dihydrate, gypsum offers a variety of useful characteristics that lend it to a multitude of productsGypsum is most widely found in the construction industry as gypsum wallboard, as well as other construction materials that rely on gypsum's ability to harden into a cement (PDF) Gypsum EBookpdf Prabir Datta Academiaedu