A new modelbased approach for power plant Tube

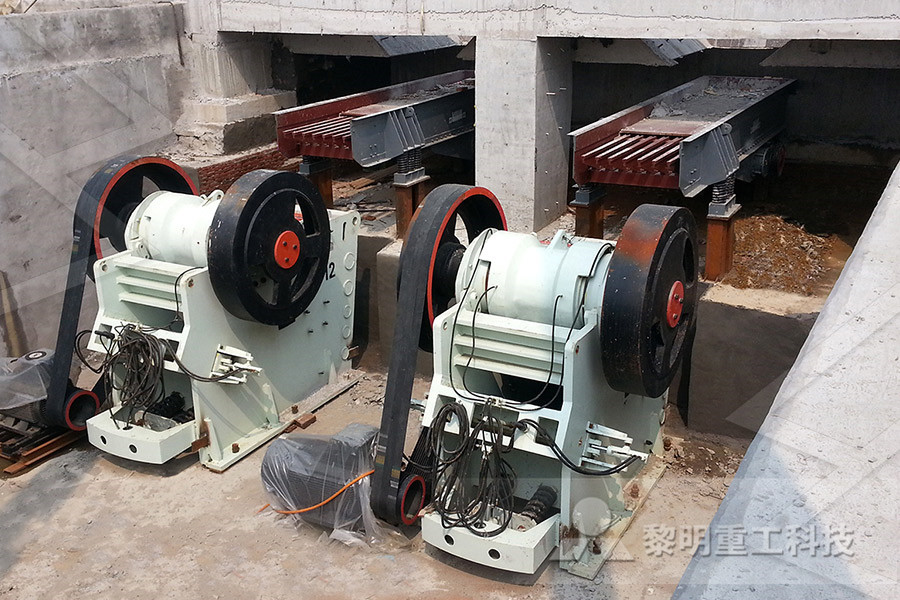

Compared with the Vertical Spindle mills, Tubeball mills have a much higher grinding capacity However, there are fewer literatures found in studying Tubeball mill operation compared with the Vertical Spindle mill Ma et al introduced a black box Neural Network model for Tubeball mills in 2005 Although the Neural Network can have a good ball tube mill 1 content • an over view of balltube mill • instrumentation involved in balltube mill 2 an over view of balltube mill • mill operation principlemill operation principle • primary airprimary air • motor pumpsmotor pumps • girth gear systemgirth gear system • advantages advantages disadvantages of balltubedisadvantages of balltube Ball tube mill SlideShareBall mills with a drum length to diameter ratio greater than 15 are referred to as tube mills Ball mills may be primary or secondary grinders Primary grinders are fed from crushers such as a jaw crusher Secondary grinders are fed from other grinders eg a rod mill Ball mills are usually either of the grate (diaphragm) or overflow typeBall Mill Explained saVRee

ring and ball mill power station restauracja

Low 10 to 20 RPM Ball tube mills (16 rpm in Vindhyachal) Medium High 40 to 70 RPM 900 to 1000 RPM Bowl Mill, MPS Impact or Mill, Ball and Hammer Race mill Mill Beater Mill or Fan Mill TYPES OF MILL Tube or ball mills These are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder Ball tube mills are either pressurized or suction type In the pressurized type, the hot primary air is used for drying the coal and to transport the milled coal to the furnace In this type, leakage in the mill area is highIn the suction type, the exhauster is used for lifting the milled coal from the pulverizer to the furnace through a cycloneCOAL BASED THERMAL POWER PLANTS: COAL MILLS Coal is ground in lowspeed ball tube mill It is filled to 2035% of its volume With steel balls having a diameter varies from 3060 mm The steel balls crush and ground the lumps of coal The average speed of rotation of tube or drum is about 18 to 20 RPMBall and Race Mill ~ ME Mechanical

Ball Mill Design/Power Calculation 911 Metallurgist

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or Coal mills grind the coal into fine powder, and the primary air entering the mill dries and drives the coal into the power plant furnace for combustion A similar loop is valid for a ballandtube mill, which is discussed separately in the next section As VSMs have come to represent the bulk of the power station mill fleet, the Coal Mill an overview ScienceDirect Topics Tube mills, similar to those used in the gold mining industry, produce finerground coal, as was well proven at Lethabo, where the calorific value of the coal is equivalent to that of a Provita Corrective measures needed for the boiler and mill

BALL TUBE MILL GEARBOX REBUILDS Babcock Power

200 ball tube mills and has the technology and expertise to help you keep your ball tube mills running at optimal efficiency, insuring that you meet your customer’s demand for clean, efficient energy Riley ball tube mill gearbox rebuilds are a practical alternative to new gearbox replacementLow 10 to 20 RPM Ball tube mills (16 rpm in Vindhyachal) Medium High 40 to 70 RPM 900 to 1000 RPM Bowl Mill, MPS Impact or Mill, Ball and Hammer Race mill Mill Beater Mill or Fan Mill TYPES OF MILL Tube or ball mills These are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinderring and ball mill power station restauracja Exxon™ and Mobil™ fuels and programs For businesses For businessesRod and Ball Tube Mills, TBR TBB TBC BSB BSR

Walloon Coals: Their Properties and Power Station

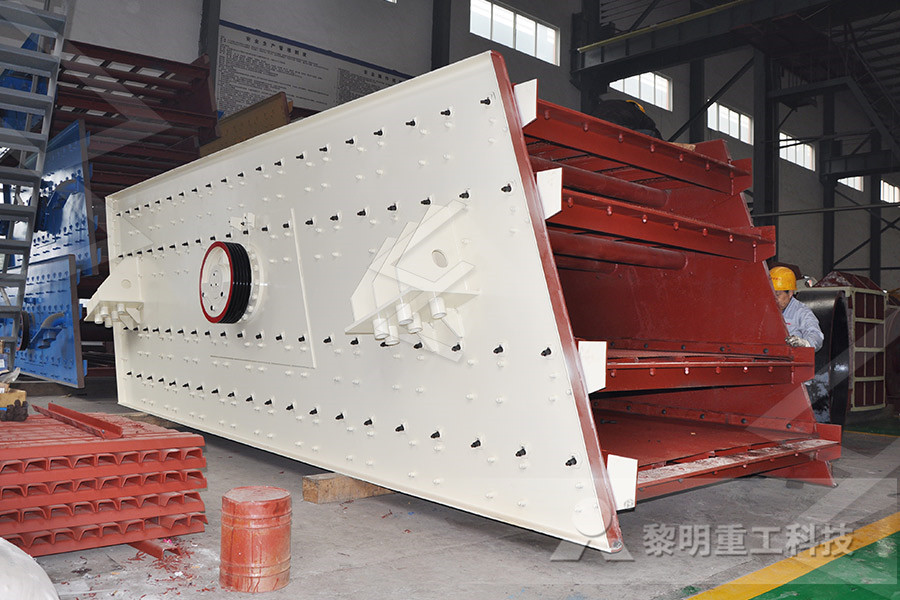

passing 75ym), for the following respective power station mills Tarong (Unit 4) ringball mills (40 t/h nominal capacity) ringroll mills (38 t/h nominal Swanbank A (Units 3 6) — capacity) • Swanbank B (Unit 3) — tubeball mills (30 t/h nominal capacity) QUEENSLAND COAL MARCH 1998 31 Figure 9C — Mitchell tubeball mill 400 300 200 100 Figure — ringball mills (with 5 MPa loading) (a) coal 52, 115 12%) mills at Tarong Power Station, the trials conducted to date have been too short in duration for any assessment of wear propensity to be made Experience with the roll mills at Swanbank A Power StationWalloon Coals: Their Properties and Power Station Tube mills use steel balls as grinding media Due to wear in the abrasive environment it is necessary to charge new balls periodically to maintain a steady balanced ball charge in the mill The amount and ball size distribution in this charge, as well as the frequency with which new balls are added to the mill, have significant effects on the Exploring ball size distribution in coal grinding mills

MILLS IN A THERMAL POWER STATION PART I

Choice of MILLS depend on the coal characteristic of the fuel Number of mills guide the height of furnace There are different type of mills , Bowl Mill, Tube mill , Ball and race mills etc are available in India There are pressurised Mill and suction type Mill I will limit my discussion on BHEL make pressurised Mills BHEL supplied other COAL MILL/PULVERIZER IN THERMAL POWER PLANTS SHIVAJI CHOUDHURY Medium High 10 to 20 40 to 70 900 to rpm rpm 1000 rpmType Ball tube Bowl Hammer mill Ball race mill millDominating Attrition Crushing Impactprinciple 101Designation of CE Bowl Mills 17 11Bowl Mill Grinding rolls 18Coal mill pulverizer in thermal power plantsComponents of Coal Fired Thermal Power Station: Coal Preparation; i) Fuel preparation system: In coalfired power stations, the raw feed coal from the coal storage area is first crushed into small pieces and then conveyed to the coal feed hoppers at the boilersThe coal is next pulverized into a very fine powder, so that coal will undergo complete combustion during combustion processThermal Power Plant Working Indian Power Sector

Hendrina Power Station Eskom

Hendrina power station is located a pproximately 40km south of Middelburg at the town of Hendrina in Mpumalanga At the time it was built it was the largest station to be designed by ESCOM (Electricity Supply Commission), with an ultimate generating capacity of 2 Low 10 to 20 RPM Ball tube mills (16 rpm in Vindhyachal) Medium High 40 to 70 RPM 900 to 1000 RPM Bowl Mill, MPS Impact or Mill, Ball and Hammer Race mill Mill Beater Mill or Fan Mill TYPES OF MILL Tube or ball mills These are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinderring and ball mill power station restauracja Figure 9C — Mitchell tubeball mill 400 300 200 100 Figure — ringball mills (with 5 MPa loading) (a) coal 52, 115 12%) mills at Tarong Power Station, the trials conducted to date have been too short in duration for any assessment of wear propensity to be made Experience with the roll mills at Swanbank A Power StationWalloon Coals: Their Properties and Power Station

Walloon Coals: Their Properties and Power Station

passing 75ym), for the following respective power station mills Tarong (Unit 4) ringball mills (40 t/h nominal capacity) ringroll mills (38 t/h nominal Swanbank A (Units 3 6) — capacity) • Swanbank B (Unit 3) — tubeball mills (30 t/h nominal capacity) QUEENSLAND COAL MARCH 1998 31 Exxon™ and Mobil™ fuels and programs For businesses For businessesRod and Ball Tube Mills, TBR TBB TBC BSB BSR Ball Mills Now are the most commonly used in the cement industry, Clinker Grinding station Steel Mill Thermal Power Plant GGBFS Production Line 300,000 t/a GGBFS Plant Slag ball mill is a kind of equipment used to grind the slag into powder particles The technical that uses the tube mill on the production of slag has been very mature Ball Mills CHAENG Great Wall Machinery

Cryomill the perfect mill for cryogenic grinding

The CryoMill is a cryogenic grinder designed with user safety in mind The liquid nitrogen flows through the closed system and the user never comes into direct contact with LN 2 which ensures a high degree of operational safety The automatic cooling system guarantees that the grinding process is not started before the sample is thoroughly cooled Choice of MILLS depend on the coal characteristic of the fuel Number of mills guide the height of furnace There are different type of mills , Bowl Mill, Tube mill , Ball and race mills etc are available in India There are pressurised Mill and suction type Mill I will limit my discussion on BHEL make pressurised Mills BHEL supplied other MILLS IN A THERMAL POWER STATION PART I A tube mill is a revolving cylinder of up to five diameters in length used for fine pulverization of ore, rock, and other such materials; the material, mixed with water, is fed into the chamber from one end, and passes out the other end as slime (slurry) Ring and ball mill This type of mill consists of two rings separated by a series of large ballsTypes of pulverizers Ball and tube mills A ball mill is a

Coalmill optimisation in coalfired power stations

Many of the existing pulverised coalfired (PCF) power stations are operated at a fixed steady load (ie baseload operation) There is however a growing requirement for load following or flexible operation, which requires flexibility in most of the components of the power station Flexibility and efficiency can be improved by close control of the coal [] Hendrina power station is located a pproximately 40km south of Middelburg at the town of Hendrina in Mpumalanga At the time it was built it was the largest station to be designed by ESCOM (Electricity Supply Commission), with an ultimate generating capacity of 2 Hendrina Power Station Eskom