Gyratory Crusher,Gyratory Crushers,vertical compound

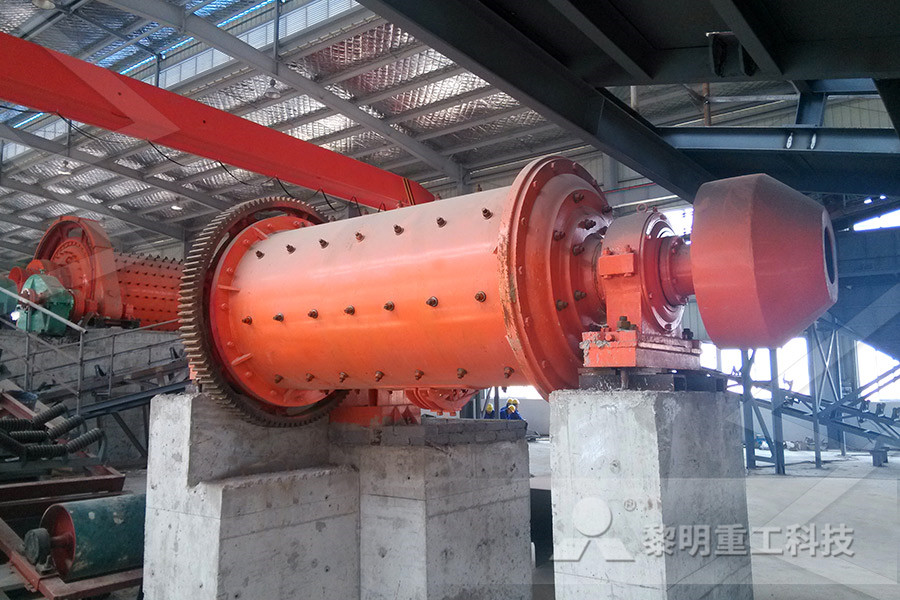

Gyratory Crusher(vertical compound crusher) is a mining and other industrial sectors crushing all kinds of hard materials typical of crushing equipment also known as compound crusher is stone production line and sand production line commonly used crusher deviceGyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher The smaller form is described as a cone crusher The larger crushers are normally known as primary crushers as they are designed to receive runonmine (ROM) rocks directly from the minesGyratory Crusher an overview ScienceDirect Topics The primary gyratory crusher breaks the material by feeding mouth into the two rollers between the extrusion crushing, finished materials naturally fall In case of too hard or can not be broken, the roller crusher Gyratory Crusher l Introduce, Working Principle JXSC

China 60110 Gyratory Crusher / Crusher Parts for

Applications: Widely used in mining industry, Quarrying Aggregate, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone, quartz and so onChina Mining Machine Gyratory Stone Impact Crusher for Crushing Plant, Find details about China Impact Crusher, Stone Crusher from Mining Machine Gyratory Stone Impact Crusher for Crushing Plant Jiangxi Hengchang Mining Machinery Manufacturing Co, LtdChina Mining Machine Gyratory Stone Impact Crusher Primary gyratory crushers are designated by two numbers These are the size of the feed opening (in inches) and the diameter of the mantle at its base (in inches) A 60″~x~89″ crusher would have an opening dimension of 60 inches (152 cm) and a diameter across the base of the mantle Gyratory Crushers 911 Metallurgist

The Advantages and Disadvantages of Gyratory

When the mine stone degree is larger than 400 mm, it needs to install expensive heavy plate type feeder; 4 Gyratory crusher is easy to start, which is unlike the jaw crusher with auxiliary tool before starting rotation heavy flywheel (startup jaw crusher exception); 5 Sheet products generated by gyratory crusher are much less than jaw crusher2 天前 The rotating speed of the movable cone of the gyratory crusher is low, the stroke is small And the ore is mainly crushed and broken and bent The cone crusher has 25 times higher rotating speed and 4 times larger swinging angle than the gyratory crusher, Cone Crusher VS Gyratory Crusher JXSC Mine Gyratory Crusher (vertical compound crusher) is a mining and other industrial sectors crushing all kinds of hard materials typical of crushing equipment also known as compound crusher is stone production line and sand production line commonly used crusher deviceGyratory Crusher,Gyratory Crushers,vertical compound

China 60110 Gyratory Crusher / Crusher Parts for

60110 Gyratory Crusher / Crusher Parts For Stone Crushing Mining Product Name: Gyratory Crusher Applications: Widely used in mining industry, Quarrying Aggregate, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone, quartz and so on When the mine stone degree is larger than 400 mm, it needs to install expensive heavy plate type feeder; 4 Gyratory crusher is easy to start, which is unlike the jaw crusher with auxiliary tool before starting rotation heavy flywheel (startup jaw crusher exception); 5 Sheet products generated by gyratory crusher are much less than jaw crusherThe Advantages and Disadvantages of Gyratory The bevel gear and pinion of the crusher are both of a cyclopalloid spiral type, which allows greater forces to be absorbed and greater drive power to be installed A B C C D F E I J H K G Gyratory crusher Weights 1) Type Feed opening Mantle diameter (oversized) Speed of eccentric bushing Max motor power Total weight of gyratory crusher Industrial Solutions Gyratory crushers

SUPERIOR® gyratory crushers

The perfect blend of experience and innovation The SUPERIOR gyratory crushers combine ’s trusted technology with the latest advancements in metallurgy to achieve peak efficiency and high output by offering: Easy maintenance and service Designed for low service requirements and ease of operation, the SUPERIOR primary gyratory will readily fit into any existing or proposed crushing plant HGT Hydraulic Gyratory Crusher HGT Hydraulic Gyratory Crusher is a primary crusher integrated mechanical, hydraulic, electrical, automated and intelligent control together Producing a modern Stone Crusher Plant,Concrete Batching Plant, Crushing, Screening and Washing Plant facilities over the years in China and abroadCrushers, Grinding Mill, Mobile Crusher Machine For The gyratory crusher has capacities starting from 1200 to above 5000 t/h To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier Therefore, primary gyratories require quite a massive foundation The cone crusher is a modified gyratory crusherCrushers an overview ScienceDirect Topics

cone crusher machine,stone cone crusher,hydraulic

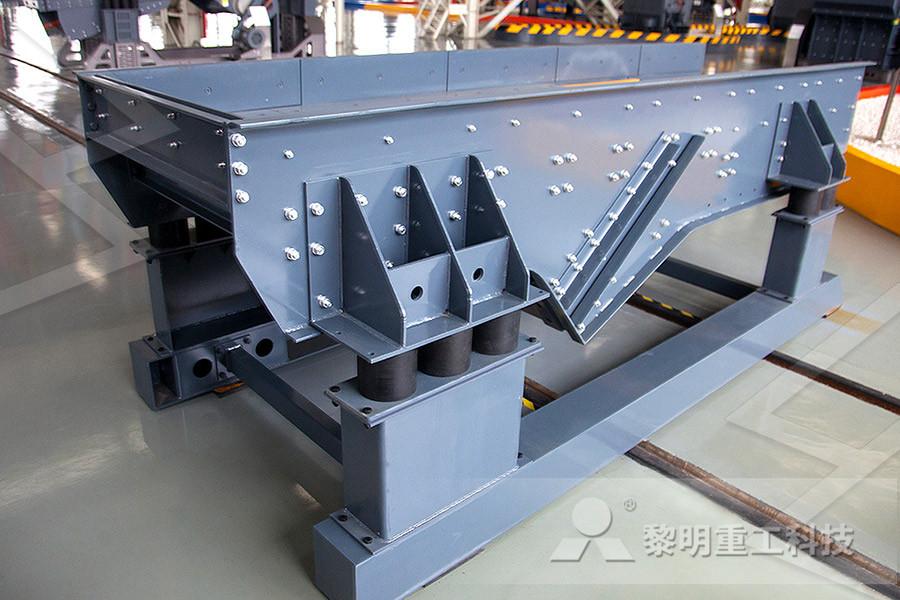

Compound Cone Crusher gyratory crusher; STONE CRUSHING MACHINE ZXC European Type Jaw Crusher Jaw Crusher Sand Making Machine Impact Crusher Vertical Shaft Impact Crusher; SCREENING SAND WASHING XL series spiral sand washing machine ZSW Series Vibrating Feeder GZT Series Vibrating Feeder Circular Vibrating Screen XS Series Sand Washer; MOBILE At present, our equipments have been exported to many countries and regions such as Southeast Asia, Mideast, Africa, Europe etc and highly appreciated by our customers "DongMeng" has become one of the most important manufacture and export bases of stone crusher and sand making equipment in Chinadifference between cone and gyratory crusher Sanme Provides highquality crushers, jaw crusher, cone crusher, mobile crusher and sand maker as the main product while feeder, belt conveyor and powder separator as the mating equipmentsCrusher,Cone Crusher,Mobile CrusherSHANGHAI

Gyratory Crusher,Gyratory Crushers,vertical compound

Gyratory Crusher (vertical compound crusher) is a mining and other industrial sectors crushing all kinds of hard materials typical of crushing equipment also known as compound crusher is stone production line and sand production line commonly used crusher deviceChina Mining Machine Gyratory Stone Impact Crusher for Crushing Plant, Find details about China Impact Crusher, Stone Crusher from Mining Machine Gyratory Stone Impact Crusher for Crushing Plant Jiangxi Hengchang Mining Machinery Manufacturing Co, LtdChina Mining Machine Gyratory Stone Impact Crusher When the mine stone degree is larger than 400 mm, it needs to install expensive heavy plate type feeder; 4 Gyratory crusher is easy to start, which is unlike the jaw crusher with auxiliary tool before starting rotation heavy flywheel (startup jaw crusher exception); 5 Sheet products generated by gyratory crusher are much less than jaw crusherThe Advantages and Disadvantages of Gyratory

60110 Gyratory Crusher / Crusher Parts for Stone

60110 Gyratory Crusher / Crusher Parts For Stone Crushing Mining Product Name: Gyratory Crusher Applications: Widely used in mining industry, Quarrying Aggregate, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone, quartz and so onStone Crusher Manufacturers for Sand, Quarry, Mining Gyratory Crusher Gyratory crusher is a new type of crusher that can replace fine jaw crusher and cone crusher It consists of a concave surface and a conical head, both of which are usually lined with manganese steel The inner cone has a slight circular movement but doesn't rotate Chat gyratory crusher for mining stone crusher machineHGT Hydraulic Gyratory Crusher consists of beam, upper frame, middle frame, lower frame, moving cone, eccentric sleeve, transmission part and hydraulic cylinder part Horizontal shaft driven by motor rotates constantly Then horizontal axis makes eccentric sleeve rotate by gear, after that eccentric sleeve will drive the moving cone to swing HGT Hydraulic Gyratory Crusher – Stone Crushers

gyratory crusher parts specification stone crusher

gyratory crusher parts specification stone crusher machine Crushing Machine PartsMn22 Jaw Plate Suit for JawCrusherC200 SparePartsProduct Description High manganese steel wear resistancepartswildely used in the JawCrusher, ConeCrusher,ImpactCrusher,Gyratory Crusherand etc HytonCasting produce High manganese casting liners mainly include Jaw Plate,Mantle, Bowl Liner, Features of the Gyratory Crusher High capacity per dollar of investment, Annular discharge opening minimizes slabbing; makes for more cubical product Shape of receiving openings favourable for slabby material This, plus point 2, gives the machine a distinct advantage over the jaw for handling thinly stratified stoneGyratory VS Jaw Crushers: Advantages Disadvantages The bevel gear and pinion of the crusher are both of a cyclopalloid spiral type, which allows greater forces to be absorbed and greater drive power to be installed A B C C D F E I J H K G Gyratory crusher Weights 1) Type Feed opening Mantle diameter (oversized) Speed of eccentric bushing Max motor power Total weight of gyratory crusher Industrial Solutions Gyratory crushers

Advantages and Disadvantages of Gyratory Crusher

Gyratory crusher is a coarse crushing machine and is mainly used for coarsely crushing rocks with different hardness in ore beneficiation industry and other industrial departments Other than gyratory crusher, jaw crusher is also a coarse crushing machine In order to correctly choose and reasonably use the coarse crushing equipment, it is necessary to know the advantages and