Crusher an overview ScienceDirect Topics

Crushed ore feeds this bin continuously and the bin overflows to a small conveyor feeding a dead stockpile In the event of a primary crusher failure, the crusher loader is used to reclaim the stockpile via the surge bin, which doubles as an emergency hopper • For coarse ore, the next alternative is a coarse ore Clay Ore Crusher Clay crusher in the course of large mill ore from the destruction of part of the formation of 7525 mm sizefraction, with the ore in the same grain size and gravel with a stone the size of the critical products Since the grinding process of actually making most of this product are not subject to the next brokenClay Ore CrusherClay Ore Crusher,Clay Ore Crushing The gyratory crusher shown in Figure 26 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circle The crushing action takes place round the whole of the cone and, since the maximum movement is at the bottom, the characteristics of the machine are Gyratory Crusher an overview ScienceDirect Topics

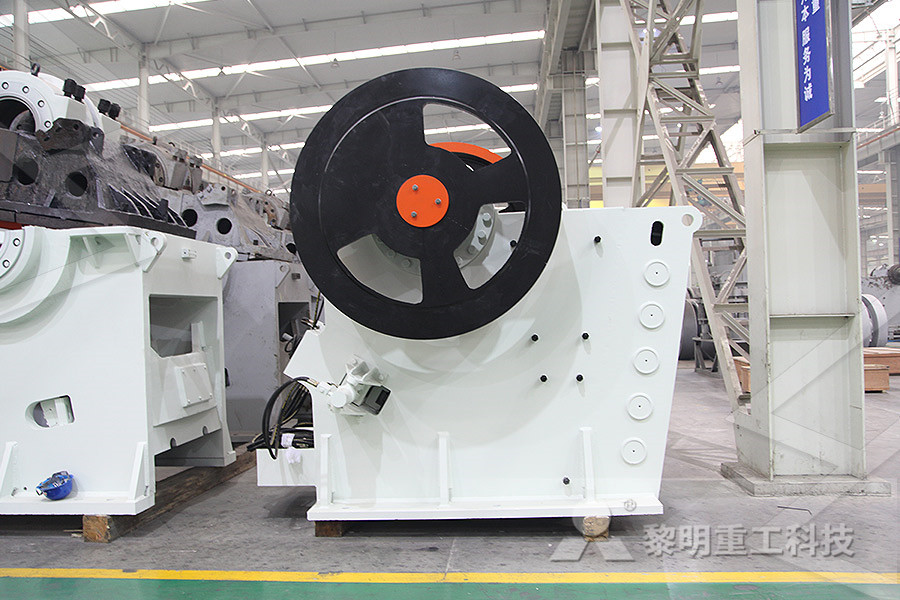

Assessing the energy efficiency of a jaw crusher

Given a set of parameters of a Jaw crusher the Maximum flow (Q M) is calculated as : (A15) Q M = 60 L t Ω Cr w (2 L min + L t) (R R + 1) ρ f (P k) f (β) S c (t/h) where 05 ≤ S c [–] ≤ 1 denotes a parameter related to the surface characteristics of the jaw crusher and ρ [t/m 3] is the density of the ore The maximum wear occurred at the head of mantle where particles hit initially when entering the crusher and normal force has high values The EDEM simulations showed a great potential to model the crushing of iron ore The DEM model will be used to optimize the performance of the cone crusherApplication of DEM to simulate a cone crusher To limit the maximum feed size to the crusher improving blasting pattern in the mine to get P80 around 250 mm To install a protective grate 600 mm slot (parallel bar separated 600 mm) recommends 850 mm as maximum feed size for medium hardness ore, but in this case the feed size must be limited because the ore hardness in order to improve Jaw Crusher Choke Feeding Crushing,

Crushing in Mineral Processing 911 Metallurgist

In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, Ore is typically passed from sublevels to haulage levels where it is trammed by rail to either the shaft, or to a large crusher from which it may be belted to the shaft This latter arrangement would be more likely in a mine having more than one underground crusher, or a laterally extensive ore Mining Methods VS Underground Crusher Location To participate in the 911Metallurgist Forums, be sure to JOIN LOGIN; Use Add New Topic to ask a New Question/Discussion about Crushing; OR Select a Topic that Interests you; Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent) Using Add Reply allows you to Attach Images or PDF files and provide a more complete input; Use Add Comment = to comment on Crushing Screening Questions and Answers for

Cone Crusher Parts 911 Metallurgist

Cone Crusher STEP BEARING The step bearing consists of a bronze mainshaft step, a bronze piston wearing plate, and an alloy steel washer between the two The washer is drilled for oil cooling and lubrication Both the mainshaft step and the piston wearing plate are made of high lead Since the selected crusher capacity must be in excess of 143 tons per hour, the next higher figure (159) is chosen The 159 indicates a 548 crusher size with 1″ eccentric throw With 1in eccentric throw, the motor hp allowed on the crusher is a maximum of 125Equipment Sizing: Crusher or Grinding Mill Lead Mines Due to their geological setting and ore body shape, the Missouri lead mines are both high and medium headroom operations Simple room and pillar, heading and bench, and shrinkage methods are used simultaneously in reaching the ore boundaries Main haulage is by LHD, truck, or by rail, with the recent trend being toward trackless Mining Methods VS Underground Crusher Location

China Stone Crushers Including Jaw Crusher, Cone

Spring cone crusher and css cone crusher Spring cone crusher is widely used in metallurgy, building, chemical industry and silicate industry It's suitable for kinds of ore and rocks which the compressive resistance is below 300Mpa, such as iron ore, copper ore, limestone, quartz, granite, sandstone etcThe gyratory crusher shown in Figure 26 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circle The crushing action takes place round the whole of the cone and, since the maximum movement is at the bottom, the characteristics of the machine are Gyratory Crusher an overview ScienceDirect Topics The main roll crusher of JXSC Mining is a doubleroll It is a fine crushing which similar to a hammer crusher Crushing the iron ore, quartz stone, rock gold, rock tantalum niobium ore, rock tin ore, rock tungsten ore, manganese ore, ilmenite ore, Kalbite, limestone, river pebbles, copper oreRoller Crusher Mineral Crushing Aggregate

Clay Ore CrusherClay Ore Crusher,Clay Ore Crushing

Clay Ore Crusher Clay crusher in the course of large mill ore from the destruction of part of the formation of 7525 mm sizefraction, with the ore in the same grain size and gravel with a stone the size of the critical products Since the grinding process of actually making most of this product are not subject to the next broken The inverse of this number is considered the efficiency of the crusher, which typically ranges from 70 to 80% (NapierMunn et al, 1996) 3 Experimental31 Materials Samples of over 25 materials have been collected for testing, which include several samples of bauxites, copper ores, limestones, acid rocks, coals and an iron ore ore breakage parameter estimation from a Following blasting, the fragmented ore is loaded on a mining truck and hauled to the crusher for primary crushing Many mines employ two to three stages of crushing Some mines have the primary crusher located in the mine, using conveyors to transport the crushed ore to the secondary and tertiary crushers or directly to the millsEnergy and Environmental Profile of the US Mining

cone crushers of Great Wall Heavy Industry

As a result of maximum feeding size range is 100 mm for PF 1007 impact crusher and the maximum feeding size of raw limestone is around 320 mm So that Great Wall Company choose the PE 400 x 600 jaw crusher as primary crushing equipment In gravel production line and quarry plant, many enterprises usually adopt the way of a complete stone crushing production lineWhen it is compared with single stone crusher What are troubleshooting for problems in Stone crushing Clay Ore Crusher Clay crusher in the course of large mill ore from the destruction of part of the formation of 7525 mm sizefraction, with the ore in the same grain size and gravel with a stone the size of the critical products Since the grinding process of actually making most of this product are not subject to the next brokenClay Ore CrusherClay Ore Crusher,Clay Ore Crushing

Roller Crusher Mineral Crushing Aggregate

The main roll crusher of JXSC Mining is a doubleroll It is a fine crushing which similar to a hammer crusher Crushing the iron ore, quartz stone, rock gold, rock tantalum niobium ore, rock tin ore, rock tungsten ore, manganese ore, ilmenite ore, Kalbite, limestone, river pebbles, copper oreCrusher, Crusher Machine, Stone Crusher manufacturer / supplier in China, offering Mining Ore Machine/Crusher/High Capacity Hydraulic Cylinder Gp Cone Crusher, Mining Grinding Machine Rod Mill Ball Mill Shanghai Manufacturer (GMBZ1530), Limestone/Iron OreChina Mining Ore Machine/Crusher/High Capacity Maximum input size is limited by the machine's design Cement Crusher Manufacturer As a trusted cement crusher manufacturer, every Stedman crusher is engineered for a maximum feed size, target output size, and total capacity, but selecting a crusher on these criteria alone is merely half the task Leadzinc ore crushing processing largest manufacturer of crusher machine

Energy and Environmental Profile of the US Mining

Following blasting, the fragmented ore is loaded on a mining truck and hauled to the crusher for primary crushing Many mines employ two to three stages of crushing Some mines have the primary crusher located in the mine, using conveyors to transport the crushed ore to the secondary and tertiary crushers or directly to the mills Crushing experiments were conducted in a laboratoryscale shorthead cone crusher (Denver No 12) equipped with a power meter ()The crusher has a stroke of 5 mm, a cone angle of 44° (in relation to horizontal) and a mantle length of 150 mmThe feed opening gap is 25 mm, which is particularly convenient, since it allows feeding 50 mm diameter (2¨) split cores ore breakage parameter estimation from a The new HPT cone crusher not only improves the production capacity and crushing efficiency, but also expanded the range of applications, from limestone to basalt production to a variety of ore from the stone crushing, efficient completion of all the pieces, fine, supercrushing operationHPT Multicylinder Hydraulic Cone Crusher

belt conveyor transporter of the lead ore

Ore Dressing Inclination Of Conveyor Belt Belt Conveyor Transporter Of The Lead Ore Sobyin Tanania barite conveyor use Limestone belt conveyor design maximum inclination angle YouTube Read More Rubber Conveyor Belt For Iron Ore Separating Plant Mineral rubber belt conveyor used in ore by As a result of maximum feeding size range is 100 mm for PF 1007 impact crusher and the maximum feeding size of raw limestone is around 320 mm So that Great Wall Company choose the PE 400 x 600 jaw crusher as primary crushing equipmentcone crushers of Great Wall Heavy Industry In gravel production line and quarry plant, many enterprises usually adopt the way of a complete stone crushing production lineWhen it is compared with single stone crusher What are troubleshooting for problems in Stone crushing