equipment grizzly separation Prominer (Shanghai)

GRIZZLY SEPARATORS – GRIZZLY SEPARATION PLANTS DOVE is a major manufacturer of heavy duty Static Grizzly Feeders, designed for primary feeding of Slurry Ore to the Mineral Processing Plants – Gravity Separation Plants Wash Plants These heavy duty Grizzly Feeders are designed to regulate the feed rate for Trommel, or the Vibrating ScreenSeparation by size is a fundamental dry material processing step and equipment selection has to be properly coordinated with the rest of the process in mind, particularly size reduction equipment The idea of separating material by size is simple, but the broad range of equipment styles shows the complexity that can be involved in making the right separation technology choiceIndustrial Separation Equipment Vibrating Screen Rock Tough sells the largest selection of Grizzly rock screen equipment Perfect for mining, crushing, recycling, site development, agriculture, landscapes, and Rock Tough: Grizzly Rock Screen Equipment Rock

Static Grizzly Screen as a Rock Separator 911

The name of the equipment that performs this function is called a GRIZZLY The equipment is limited to a maximum size of rock that it can accept The grizzly is a pattern of heavy steel bars that are laid down in a grid pattern This grid will allow the small rocks to go through The larger rock being bigger than the grid Industrial Separation Equipment The phrase “separating the wheat from the chaff” is very old proving size separation has a long history Separation by size is a fundamental dry material processing step and equipment selection has to be properly coordinated with the rest of the process in mind, particularly size reduction equipmentIndustrial Separation Equipment Vibrating Screen Alibaba offers 1,855 size separation equipment products A wide variety of size separation equipment options are available to you, such as local service location, key size separation equipment, size separation equipment

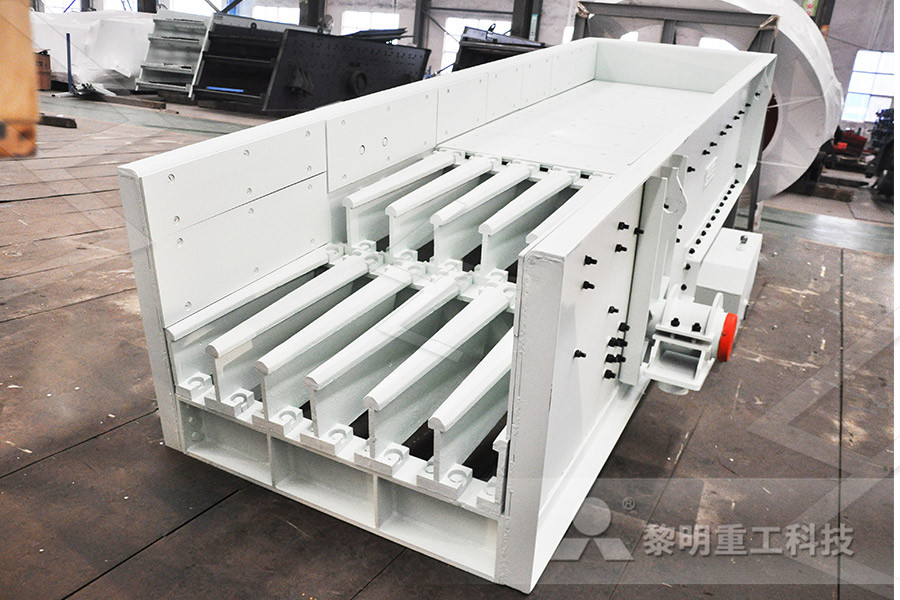

Vibrating Grizzly Feeders Classification Separation

grizzly feeders vibrating – grizzly separators DOVE Vibrating Grizzly Feeders are designed for continuous and efficient classification, separation of the ore and aggregate for sizing, removing the unwanted and oversize materials and bypassing the smaller particles for the Crusher, or Trommel, and the processing plant, which results in maximizing the plant capacity A description of the process is as follows: soil is loaded onto either a 2in or 4in grizzly The oversize material is removed by hand; the undersize passes through the grizzly into a feed hopper The material in the feed hopper is fed, by a drag flite conveyor, to a trommelParticle size separation via soil washing to obtain Separation Experts personnel have been in the business of material separations for 35 years You can trust our experience and know how Talk to us about your application Let us evaluate the best method for you, at the least cost Our equipment from Rollier is manufactured using the best first class materials, to exacting standardsSEPARATION EXPERTS – We know how to separate by

Shop Tools and Machinery at Grizzly

Grizzly Industrial, Inc is a national retail and internet company providing a wide variety of highquality woodworking and metalworking machinery, power tools, hand tools and accessories By selling directly to end users we provide the best quality products at the best price to professionals and hobbyistsequipment grizzly separation Static Grizzly Screen as a Rock Separator Separation by size is a fundamental dry material processing step and equipment selection has to be properly coordinated with the rest of the process in mind, particularly size reduction equipment The idea of separating material by size is simple, but the broad range equipment grizzly separation Prominer (Shanghai) DOVE Vibrating Grizzly Feeders are designed for continuous and efficient classification, separation of the ore and aggregate for sizing, removing the unwanted and oversize materials and bypassing the smaller particles for the Crusher, or Trommel, and the processing plant, which results in maximizing the plant capacityVibrating Grizzly Feeders Classification Separation

Gold Separationvibrating Feeder

Grizzly size separation equipment size separation equipment grizzly size separation equipment grizzlygold grizzly vibrating feeders youtube 8 jan 2014 gold grizzly vibrating feeder for gold separation Mechanical screeningWikipedia Mechanical screening often just called screening is the practice of taking granulated ore material and Vibrating Grizzly Ore Feeder, Vibrating Grizzly Stone Feeder, Vibrating Grizzly Rock Feeder manufacturer / supplier in China, offering Mining Equipment Rock Grizzly Vibrating Feeder, Ore Processing Plant Mini Gold Stone Crusher, Small Size Jaw China Mining Equipment Rock Grizzly Vibrating Separation Experts personnel have been in the business of material separations for 35 years You can trust our experience and know how Talk to us about your application Let us evaluate the best method for you, at the least cost Our equipment from Rollier is manufactured using the best first class materials, to exacting standardsSEPARATION EXPERTS – We know how to separate by

Grizzly Screens For Sale Soil, Sand, Rock Grizzly

Grizzly screens for sale: 29 listings Static or vibratory screens, fixed or adjustable deck bar openings to sort and separate your material, whether it be rock, soil, or sand A sluice box with attached grizzly, and some sort of spraybar with a fitting for a water hose, is often called a high banker or highbanker For machinedigging operations, there are primarily two kinds of equipment used to remove cobbles and gravel above some size The most common is a trommel The blue one to the right is fairly small; a BC Placer Placer Mining EquipmentEvery material processing system has to have a starting point Accurate, consistent feed rates are critical to ensure repeatable results in size reduction and separation systems Overfeeding overloads conveyors and processing equipment, resulting in costly maintenance and downtime Underfeeding robs production and increases costsFeeder System for Conveyors Material Processing

Gold Extraction Recovery Processes 911 Metallurgist

A sluice is defined as a channel through which controlled amounts of diluted slurry Sluice box and riffles are one of the oldest forms of gravity separation equipment The size of this equipment is variable and range from small and portable metallic models to large units Small models are employed for prospecting purposesMD Vibratory Screens The McLanahan MD Vibratory Screen is a compact, highcapacity dry screening unit used in a variety of industries It is capable of screening more tons per hour per square feet of screen surface area and handling larger capacities than conventional screens, while occupying the same — or less — floor spaceMD Vibratory Screens McLanahanPicture of grizzle screening in size separation Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Picture of grizzle screening in size separation, quarry, aggregate, and different kinds of mineralsPicture of grizzle screening in size separation

Vibrating Grizzly Feeders Classification Separation DOVE

DOVE Vibrating Grizzly Feeders are designed for continuous and efficient classification, separation of the ore and aggregate for sizing, removing the unwanted and oversize materials and bypassing the smaller particles for the Crusher, or Trommel, and the processing plant, which results in maximizing the plant capacityG0863 Grizzly Growler Cyclone Separator Turn your stock singlestage dust collector into a heavyduty cyclone in minutes! The G0863 Grizzly Growler Cyclone Separator provides industry leading dust and wood chip separation to handle all your demanding shop needs The 6" inlet port and two 4" ports allow you to connect multiple machinesGrizzly Growler Cyclone Separator at GrizzlyGrizzly size separation equipment size separation equipment grizzly size separation equipment grizzlygold grizzly vibrating feeders youtube 8 jan 2014 gold grizzly vibrating feeder for gold separation Mechanical screeningWikipedia Mechanical screening often just called screening is the practice of taking granulated ore material and Gold Separationvibrating Feeder

SANDVIK SG SGH GRIZZLY SCREENS

SANDVIK SG SGH GRIZZLY SCREENS 3 * These values correspond to material with bulk density 1,6 t/m3 and are recommended values only (ie other figures might occur in special applications/screen sizes) ** The weight includes the weight of the grizzlies (grizzly gap appr 100 mm)The Roller Grizzly is available for both primary and secondary duties, depending on the maximum feed size ROLLER SCREEN The Roller Screens are primarily designed for coal and lignite screening as well as similar soft, nonabrasive materials like limestone These screens are superior to the vibrating equipment when the materialSANDVIK SR ROLLER GRIZZLY, ROLLER SCREEN, ROLLER Gold Dust Separation Panning Machine From Sinolinking , Find Complete Details about Gold Dust Separation Panning Machine From Sinolinking,Gold Dust Separation Machine,Gold Panning Machine,Gold Panning Kit from Supplier or ManufacturerShandong Sinolinking Import And Gold Dust Separation Panning Machine From Sinolinking

used vibrating grizzly feeder MC World

Vibrating Grizzly Feeders, Osborn Pan Feeder, Apron Feeder VIBRATING GRIZZLY FEEDER Osborn has a wide selection of VGF’s from the light duty Osborn Obex machines with a vibrator motor drive, a middle duty Osborn Telsmith series with a twin shaft drive (very often used for aggregate production) the heavy duty Osborn Linear series with a twin shaft or quadruple shaft drive and the Osborn Introduction of vibrating grizzly feeder: Vibrating feeder can feed lump or granulated materials to the other devices evenly and continuously In sand and gravel production line, the continuous feeding of the vibrating feeding machine helps avoid the blockage at receiving hopperVibrating Grizzly Feeder Vibrating Feeders Much of this equipment, ie trommels, screw classifiers, attrition mills, hydrocyclones, etc originated in the mining industry Soil is comprised of various particle size fractions and most often, the contaminants are concentrated in one size fraction In many situations, this fraction is the finer silts and clays (50 μm or less)Particle size separation via soil washing to obtain volume