raw mill blending machines

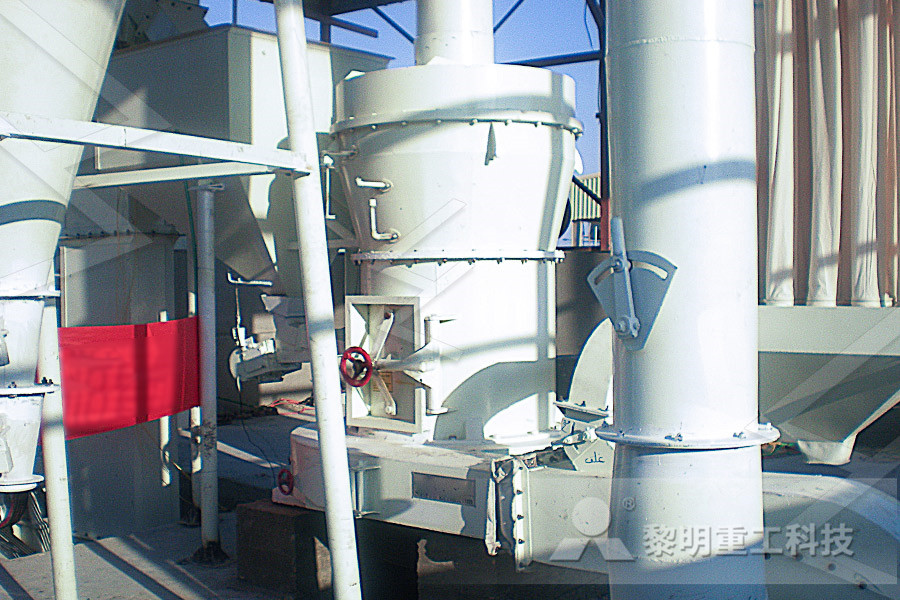

Raw material preparation From the quarry to raw meal feeding into machines and analysis equip ment is then selected, x Bulk material storage/blending/metered feeding: the raw materials are buffer stored in Flow regulation bin x Grinding/drying: the raw material is ground in the raw mill to the fineness Read moreOur raw chapati making machines are designed for very useful in places where a large quantity of chapatis is required within a limited time period Key advantage of raw chapati making machine Unique and reliable design The raw chapati making machines are highly effective as Mixing And Blending Machines Commercial Paddle The grinding process by fish feed hammer mill depend on particle size required, This kind of blending is widely applied in the feed processing industry The software optimises raw material blending to improve the quality of your product, and ensures you meet peak quality targets Propotioning blending and grindingRaw Material Propotioning And Grinding Process

What is homogeneious factor in blending silo of raw

Grinding mills, Ball Mill, Vertical Roller Mill for What is homogeneious factor in blending silo of raw mill in cement industry As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, What is homogeneious factor in blending silo of raw mill Raw milk vending machines provide a convenient outlet for residents to stock up on what is considered a healthy and wholesome food Selfservice machines may be found at farmers markets and small farms as well as in shopping centers and near Raw Milk Vending Machines Flourish in Europe2 天前 eirich machines offers tailormade solutions for today's mixing challenges! For many decades EIRICH Machines has been delivering advanced technology solutions for industrial process engineering Key milestones in the development of a wide variety of industries and applications are inextricably linked to EIRICH and American Process Systems technologyEirich Machines Industrial blending, Industrial Mixers

Raw Milk Vending Machines Take Over Europe

Europe’s embrace of raw milk vending machines isn’t new Such daring dispensers of unpasteurized dairy can be found in France, Croatia, Switzerland, Installed directly downstream of the raw mill, the POLAB® AOT takes raw meal samples at short intervals, finegrinds them, analyses them with its energy dispersive Xray fluorescence analyser and controls the raw material composition and mill feeding Use of the POLAB® CNA analysis system upstream of the blending bed ensuresRaw material preparation From the quarry to raw meal In grain milling, up to 80% of costs are caused by raw materials Our processes and equipment are therefore designed to produce highquality products and maximum yields If you increase yields by even a fraction, it goes straight to your Wheat and Grain Milling Group

Raw milk should be sold in vending machines, says

Sales of raw milk are subject to control because it may contain harmful bacteria such as E coli or salmonella (Getty) Raw milk should be sold in vending machines, says food standards bodyBall Mill Dryer Machine Sand Maker Cement Mill Raw Mill Building 05 Blending and of Cement Plant Ball Mill and Grinding Machine offered by Afrisam cement roodepoort plant raw mill blending machines Mining amp World Quarryblending machine of cement millflow chart of raw mill and blending mill pdf download Ering the transported raw materials and tapping quantity and coke outputs on the other hand, steelworks determine the following schedules based on the schedules for ships and blending raw materials determined by the head office such that they can carry out daily operafig target of planning, scheduling and logistics related to raw materialflow chart of raw mill and blending mill pdf download

Blending Machines Manufacturer, Supplier, Exporter In

WAHAL ENGINEERS Manufacturer,Supplier and Exporter of engineering goods and machines like Blending Machines,Multi Rings Sheer Mill etc at reasonable prices from India The blending procedure is scalable for volumes between four to 12,000 liters For highest flexibility, blending containers with different capacities can be used The patented Bohle blending process guarantees the effective mixing of batches between 20 – 85 % and with densities between 02 – 12 kg/lBohle Container Blenders PM Pharmaceutical IndustryDifferent methods of blending are implemented, according to the nature of raw material, size, and density Based on method and application, they are named as Ribbon Blender, Cone Blender, Paddle Blender etc Mostly all Blenders are fabricated with contact metal Stainless Steel 304 Mixing and Blending Equipments Pilotsmith India

Rubber Mixing Mill MachinesMixing Mill

Top Rubber Mixing Mills Machines in India, Priemerrubbermachinery is the manufactuer of Uni Drive Mixing mill in India These rubber mixing mill machines ensure perfect and uniform blending of natural and synthetic rubber with other raw materialsThe machinery enables the processing of raw animal fibers or manmade fibers into yarn The Belfast Mini Mill is capable of processing small batches down to ounces or grams in size or large commercial size batches of tons Although the individual machines are small, relative to a large commercial mill, they have been designed to be modularFibre Processing Machinery Mini Mills Up to the draw frame, each raw material can be processed separately on the machines best suited to it An additional blending passage must be inserted before the two classic draw frame passages in the cotton spinning mill The main disadvantage, aside from the necessity of a third draw frame passage, is the poor transverse blending in the productBlending Process of Yarn Making TEXINLIFE

Wheat and Grain Milling Group

Get your milling solutions from one source worldwide at With 150 years of experience, is a leader in milling design, processes, machinery, automation and maintenance All designed for high quality and high yieldsCleaning and Grading Machines We have different types of cleaning and grading machines which is suitable for different types of raw materials This cleaning and grading system takes care of removing impurities like dust, stones, over size and under size particles in the raw materialCleaning and Grading machines Pilotsmith India Pvt Top Rubber Mixing Mills Machines in India, Priemerrubbermachinery is the manufactuer of Uni Drive Mixing mill in India These rubber mixing mill machines ensure perfect and uniform blending of natural and synthetic rubber with other raw materialsRubber Mixing Mill MachinesMixing Mill

flow chart of raw mill and blending mill pdf download

flow chart of raw mill and blending mill pdf download Ering the transported raw materials and tapping quantity and coke outputs on the other hand, steelworks determine the following schedules based on the schedules for ships and blending raw materials determined by the head office such that they can carry out daily operafig target of planning, scheduling and logistics related to raw material The blending procedure is scalable for volumes between four to 12,000 liters For highest flexibility, blending containers with different capacities can be used The patented Bohle blending process guarantees the effective mixing of batches between 20 – 85 % and with densities between 02 – 12 kg/lBohle Container Blenders PM Pharmaceutical Industryraw mill blending cement Skool Book Apr 5, 2015 , vertical raw mill in cement plant animation , raw mill blending cement , Detail Caculation Of Raw Mill In , get price blending silo for raw mill raw mill blending cement ekliefkrismiscoza

Blending Process of Yarn Making TEXINLIFE

Up to the draw frame, each raw material can be processed separately on the machines best suited to it An additional blending passage must be inserted before the two classic draw frame passages in the cotton spinning mill The main disadvantage, aside from the necessity of a third draw frame passage, is the poor transverse blending in the product 4 The process chain at a glance xCrushing: crushers break up the raw material delivered from the quarry and provide the raw mill with the feed size range it requires Crushers xRaw material analysis:the POLAB® CNA online analyser provides the first data regarding the chemical contents and/or homogeneity of the raw materialRaw material preparation From the quarry to raw meal RAW MATERIAL MIXING Drawing is the final process of quality improvement in the spinning mill and quality of draw frame sliver determines the final yarn quality Draw Frame process includes Equalizing, Parallelizing, Blending and Dust removal The quality improvements are obtained at the cost of additional expenditure on machines Omax Cotspin Pvt Ltd

Wheat and Grain Milling Group

Get your milling solutions from one source worldwide at With 150 years of experience, is a leader in milling design, processes, machinery, automation and maintenance All designed for high quality and high yieldsCleaning and Grading Machines We have different types of cleaning and grading machines which is suitable for different types of raw materials This cleaning and grading system takes care of removing impurities like dust, stones, over size and under size particles in the raw materialCleaning and Grading machines Pilotsmith India Pvt Bale Blending Blending can be defined as intermingling of different diversities or grades to yield certain quality which is why blending proportion can be forecast and easily replicated Importance of Blending Imparts the essential appearances to the end product (eg: PC, CVC) Compensate for dissimilarities in the qualities of the raw materialBale Management in Spinning: Blending Mixing