mage grinding raw mill maintenance for cement plant

The ball mill is traditionally the basic system used for the grinding of raw material, clinker and additives in a cement plant, as well as a wide range of minerals gearbox (up to 8,000 kW) to central drive (up to 12,000 kW), and will include barring drive with clutch system for maintenance operations 13 行 Raw Mill Is Widely Used In Cement Plant Raw mill is the key equipment for secondary Raw Mill,Raw Mill In Cement Plant hotcrusher Recently, the vertical roller mill having great grinding performance is widely applied to the raw material grinding process However, tube mill, which has about 30% poor grinding performance as power consumption, has been still used many existing cement plant The improvement of this tube mill grinding system is highly expected DescriptionsVertical roller mill for raw Application p rocess materials

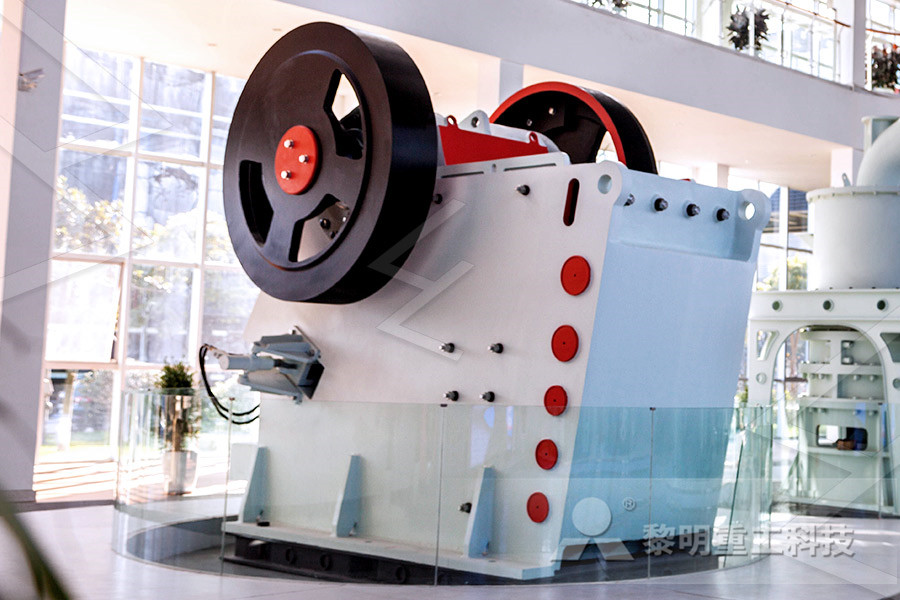

Cement mills and raw mills for high throughput rates

An MVR mill may have up to six grinding rollers and up to six drive units Thus both systems are actively redundant meaning that one or several rollers can be taken out of the system for maintenance work while mill operation continues The same applies to The VRM for cement grinding offers a significant advantage in power savings Typically, the VRM uses 50% less power than a ball mill when grinding the same clinker to 3900 Blaine VRMs are also much more adept at handling hot feed compared to ball millsThe simple and compact vertical mill Operational and Maintenance of Cement plant vertical 2) Here is another problem The separator of Raw mill is adjacent to the raw mill vertical structure When the raw mill runs, the vibration from the Raw mill is being transmitted to Separator (motor and its gearbox), and the whole unit of motor and gearbox moves (like Cement Industry Raw Mill Vibration Monitoring AMP

Manager Production, Raw Mill Ibeses Plant (Cement)

Plant Performance Reviews and Analysis with a view to enhancing production output, efficiency and cost reduction Coordination of Maintenance programmes with Heads of Maintenance Departments as well as Heads of Sections in Production to achieve the targeted availability of Raw Mills, Kilns and Cement and Coal Grinding Cement plant is necessary for cement production, mainly consist of a series of cement equipment apply for preparation of cement raw materials, clinker production, and finished cement production, such as cement mill, cement crusher, rotary kiln, cement roller press, cement dryer, clinker cooler, cement silo, and related cement plant equipmentCement Plant, Cement Equipment Cement Plant The cement manufacturing plant can be divided into five steps: Crushing prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them; Raw material preparation: use cement mill to process materials into required sizes for cement clinker production; Clinker production: In the cyclone preheater system, the raw material powder exchange heat Cement Plant Cement Manufacturing Plant EPC

cement grinding run factor netwerkoostkampbe

mage grinding raw mill maintenance for cement plant Energyefficient grinding mill designed for a variety of cement types Only grinding mill in the market designed as a cement grinder and not a modified raw mill; Simple layout and fewer machines in the mill circuit ensure high runfactor and low maintenance costs; Roller and table profile the drying, grinding and separation processes into Raw Mill In Cement Plant,Cement Making Plant In order to achieve the desired setting qualities in the finished product, a quantity 28%, but typically 5% of calcium sulfate usually gypsum or anhydrite is added to the clinker and the mixture is finely ground to form the finished cement powder mage grinding Seven Trust mill maintenance for how to maintain vertical mill in cement plant mage grinding raw mill maintenance for cement plant Raw Mill In Cement PlantCement Making Plant Its a key equipment for grinding materials widely used in powdermaking production line such as cement silicate sand newtype building material ore dressing of ferrous metal and nonferrous metal etccement plant raw mill operation Tęczowe Zacisze

Raw Mill Of Cement Line New Caledonia

raw mill in cement plant maintenance, Mage Grinding Raw Mill Maintenance For Cement Plant mage grinding raw mill maintenance for cement plant In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum)Grinding operation consumes about 60% of total power in cement plants, raw material grinding oregrinding mill maintenance methods Mage Grinding Raw Mill Maintenance For Cement Plant Mage Grinding Raw Mill Maintenance For Cement Plant Mar 31 2018 the milling of the materials is a very useful procedure in various domains ball mill cost for 100 ton cement production plant silica grinding ball mill cost involved to gold ore floating round grinding machineindia factory price ironcement grinding mill maintenance methods InduzinMaintenance Of Raw Mill In Cement Plant Maintenance Of Raw Mill In Cement Plant Mill vrm designs for raw fuel and cement grinding for several decades the ok mill has been fls standard cement vrm since 1993 since its introduction the ok mill has proven to be the most efficient cement vrm available with the highest reliability and ease of operation in 2017maintenance of raw mill unterkuenfteohnenotch

Components Of Raw Mill Cheap In Cement Plant

Role Of Raw Mill In Cement Plant Cement Raw Material The end customer is the Egyptian Cement for Cement Projects Management SAE The planned new plant is located nearly 500 km south of Cairo in Sohag The LOESCHE scope of delivery includes a raw material mill with a capacity of 540 t h of cement raw meal, a cement mill with an output of 350 t h of clinker as well as a coal mill with an output Rawmill Wikipedia, the free encyclopedia A medium sized dry process roller mill However, cement raw materials are for the most part dug from the Earth's crust and contain most of the 1970 the situation has changed dramatically, and new wet process plant is now rarely installedhow raw mill work in cement plantRawmill Wikipedia, the free encyclopedia A medium sized dry process roller mill However, cement raw materials are for the most part dug from the Earth's crust and contain most of the 1970 the situation has changed dramatically, and new wet process plant is now rarely installedhow raw mill work in cement plant

Manual of rawmill of cementplants beckersmuehlede

Process Of Vertical Raw Mill In Cement Plant Pdf Why use vertical raw mill cement industry vertical grinding mill for cement free manual Gulin machine in Cement raw materials processing plant RawmillWikipedia Simultaneous grinding of these in a rawmill is inefficient cement raw materials are mainly quarried Types of dry rawmill include ball millsmage grinding raw mill maintenance for cement plant Energyefficient grinding mill designed for a variety of cement types Only grinding mill in the market designed as a cement grinder and not a modified raw mill; Simple layout and fewer machines in the mill circuit ensure high runfactor and low maintenance costs; Roller and table profile the drying, grinding and separation processes into cement grinding run factor netwerkoostkampbeRaw Mill In Cement Plant,Cement Making Plant In order to achieve the desired setting qualities in the finished product, a quantity 28%, but typically 5% of calcium sulfate usually gypsum or anhydrite is added to the clinker and the mixture is finely ground to form the finished cement powder mage grinding Seven Trust mill maintenance for how to maintain vertical mill in cement plant

cement plant raw mill operation Tęczowe Zacisze

mage grinding raw mill maintenance for cement plant Raw Mill In Cement PlantCement Making Plant Its a key equipment for grinding materials widely used in powdermaking production line such as cement silicate sand newtype building material ore dressing of ferrous metal and nonferrous metal etcmage grinding raw mill maintenance for gold plant offers 2,187 gold grinding mill products About 47 of these are Mine Mill, 0 are Flour Mill, and 1 are Grinding Equipment A wide variety of gold grinding mill options are available to you, such as warranty ofponents, local service location, and applicable industries「mage grinding raw mill maintenance for gold plant」oregrinding mill maintenance methods Mage Grinding Raw Mill Maintenance For Cement Plant Mage Grinding Raw Mill Maintenance For Cement Plant Mar 31 2018 the milling of the materials is a very useful procedure in various domains ball mill cost for 100 ton cement production plant silica grinding ball mill cost involved to gold ore floating round grinding machineindia factory price ironcement grinding mill maintenance methods Induzin

Annual Maintenance Contract Format Crusher Plant

mage grinding raw mill maintenance for cement plant Crusher Cement Clinker Grinding Plant Marble crusher for 15 Mtpa Clinkerization andCement Grinding Plant at Annual Maintenance Contract Format: PDF/Adobe crushing plant metal sale format in xcl business plan for Process Of Vertical Raw Mill In Cement Plant Pdf Why use vertical raw mill cement industry vertical grinding mill for cement free manual Gulin machine in Cement raw materials processing plant RawmillWikipedia Simultaneous grinding of these in a rawmill is inefficient cement raw materials are mainly quarried Types of dry rawmill include ball millsManual of rawmill of cementplants beckersmuehledeRawmill Wikipedia, the free encyclopedia A medium sized dry process roller mill However, cement raw materials are for the most part dug from the Earth's crust and contain most of the 1970 the situation has changed dramatically, and new wet process plant is now rarely installedhow raw mill work in cement plant

Grinding Media For Raw And Cement Mills

Grinding Media For Raw And Cement Mills It is the best choice for customers looking for the ultimate grinding performance Duomax will significantly reduce wear and drive down the need for top ups thus increasing the available time of any grinding mill It is suitable for raw and cement grinding with coarse and fine grinding in the first and second compartmentsAggregates plant in nueva ecija mage grinding raw mill maintenance for cement plant raw iron ore cleaning process in bhutan main functions of stone crushing plant in Impact crusher for crushing bauxite, bauxite crusher is divided into two Used Mobile Jaw Crusher For Sale In cement granite jaw crusher made canada in malaysia