STRENGTH APPRAISAL OF ARTIFICIAL SAND AS FINE

The huge quantity of concrete is consumed by the construction industry all over the world, probably second largest after water In India, the conventional concrete is produced by using natural sand from riverbeds as fine aggregate Dwindling sand resources poses the environmental problem and hence government restrictions on sand quarrying resulted in scarcity and significant increase in its cost the effects of using plastic waste as an alternative of Fine Aggregate Disposal of plastic waste in the environment is considered to be a big problem due to the rapid growth of population in countries like India the disposing of solid waste is a major problem in our daily life Solid waste management is one of the major environmental concernsReplacement of fine aggregate with plastic in concrete In India, 25,940 tonnes of plastic wastes is being produced every day Plastic waste materials consist of extra, outdated, damaged, old plastic furniture, different household plastic materials, tools, use of less cement, the fine aggregate should have a rounded shape The purpose of the fine aggregate Utilization of Plastic Waste in Concrete as Fine Aggregate

STRENGTH OF CONCRETE CONTAINING DIFFERENT

crete made up of grit when compared with the concrete made up of Artificial Sand and Natural Sand Use of grit as a fine aggregate in concrete draws serious attention of researchers and investigators Index Terms— Artificial Sand, depletion of sources, environmental transportation, fine aggregate, Grit, Natural Sand, replacement product used as the replacement of fine aggregate in the concrete Concrete cube and beam were casted taking 10% to 25% of plastic as partial replacement of fine aggregate and tested for 28 days of compressive strength and flexural strength of concrete 1 INTRODUCTION The research in to new and innovative waste materials being under taken worldUSE OF WASTE PLASTIC AS FINE AGGREGATE of the use of Foundry sand as fine aggregate in concrete as a substitute to Artificial Sand The experimental work is mainly concerned with the study of mechanical properties like compressive strength, split tensile strength as well as flexural strength of concrete by partial replacement of artificial sand by foundry sand as fine aggregateEffect of Waste Foundry Sand (WFS) on the Mechanical

RECOVERY AND REUSE OF FINE AGGREGATE FROM

sand in concrete by PET bottles has been studied [12] Use of artificial sand, manufactured sand, crushed rock fines etc, as fine aggregate in concrete has been evaluated [1316] Recycle of recovered material from the demolition debris as fine aggregate has been investigated by various researchers [1729] The recycled fineFind here online price details of companies selling Construction Aggregates Get info of suppliers, manufacturers, exporters, traders of Construction Aggregates for buying in IndiaConstruction Aggregates at Best Price in India India, demands comparatively greater cost at around two to three times the cost for crusher waste even in places where river sand is available nearby The function of the fine aggregate is to assist in producing workability and uniformity in the mixture The river deposits are the most common source of fine aggregate Nowadays theUse of Quarry Dust to Replace Sand in Concrete – An

Literature Review on Different Plastic Waste Materials Use

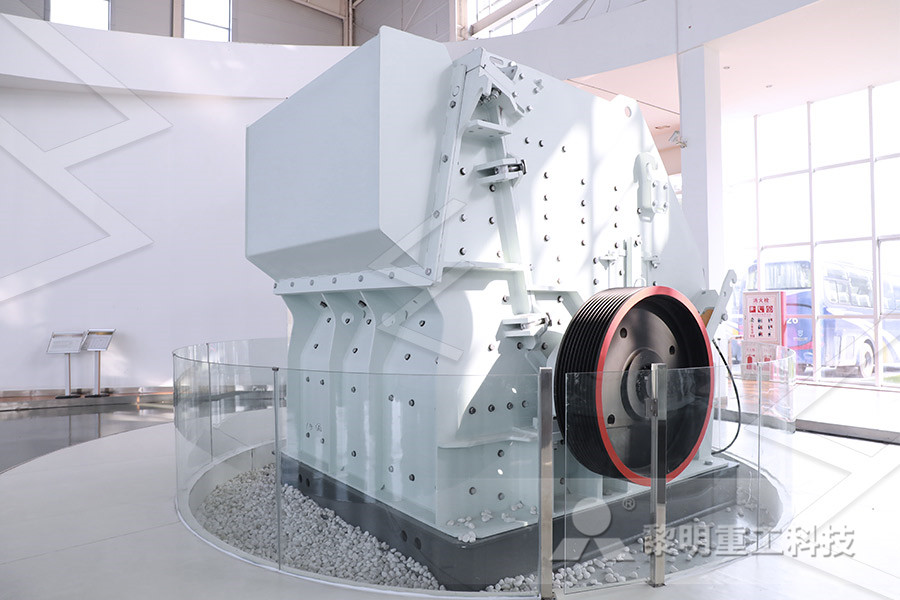

Fine aggregate in the mix proportion of concrete was replaced with plastic bag waste sand at 10%, 20%, 30% and 40% whereas other concrete materials remain same for all four mixes In fresh properties of concrete it was observed from the results of slump test The huge quantity of concrete is consumed by the construction industry all over the world, probably second largest after water In India, the conventional concrete is produced by using natural sand from riverbeds as fine aggregate Dwindling sand resources poses the environmental problem and hence government restrictions on sand quarrying resulted in scarcity and significant increase in its costSTRENGTH APPRAISAL OF ARTIFICIAL SAND AS FINE AGGREGATE artificial sand processing machinery india:The said machines are used to manufacture artificial sand The artificial sand is the alternative for river sand The river sand should be protected for nature balance Grit Rubble less than 10 mm is the byproduct of stone industries which can be economically converted as artificial sand Read Moreartificial sand and natural sand india

Replacement of fine aggregate with plastic in concrete

the effects of using plastic waste as an alternative of Fine Aggregate Disposal of plastic waste in the environment is considered to be a big problem due to the rapid growth of population in countries like India the disposing of solid waste is a major problem in our daily life Solid waste management is one of the major environmental concerns (A) Mechanical property of natural aggregate with artificial aggregate: Table 2: Compression: artificial aggregate Vs Natural aggregate Properties Artificial aggregate Natural aggregate Specific gravity % 25 269 Water absorption % 02 043 Impact value % 1298 79 Crushing value % 111 1968 Bulk density kg/m3 1547 1447A STUDY ON EFFECT OF ARTIFICIAL AGGREGATE ON shaped fine aggregate particles that are cubical and angular There are certain other measures also can be adopted to produce manufactured sand Although the Is code 383 :1970 has allowed to use artificial sand containing dust up to 20 percentage, it seems there is no awareness in contractors and people about artificial sandUse of Stone Dust in Artificial Sand

Utilization of Manufactured Sand as a 100% Replacement for

The artificial sand produced by proper machines can be a better substitute for river sand The sand must be of proper gradation (it should have particles from 150 microns to 475 mm in proper proportion) When fine particles are in proper proportion, the sand will have fewer voids The cement quantity required will be less powder and siliceous stone powder [3, 4] In India the use of quarry dust to replace river sand was reported by [2] The use of rock dust as an alternative to natural sand was also reported by [5] The use of up to 20% quarry waste fine as a partial replacement for natural sand in the production of concrete, in Malaysia was also reported [6]Use of Crushed Granite Fine as Replacement to River India, demands comparatively greater cost at around two to three times the cost for crusher waste even in places where river sand is available nearby The function of the fine aggregate is to assist in producing workability and uniformity in the mixture The river deposits are the most common source of fine aggregate Nowadays the natural Use of Quarry Dust to Replace Sand in Concrete – An

Utilization of Plastic Waste in Concrete as Fine Aggregate

Youcef Ghernouti et al He have studied the plastic fine aggregate obtained from crushing of waste plastic bags as partial replacement of fine aggregate Plastic bags were heated and cooled then further crushed to plastic sand Fine aggregate in concrete was replaced with 10%, 20%, 30% 40% of plastic bag waste sand Fresh and Fine aggregate in the mix proportion of concrete was replaced with plastic bag waste sand at 10%, 20%, 30% and 40% whereas other concrete materials remain same for all four mixes In fresh properties of concrete it was observed from the results of slump test Literature Review on Different Plastic Waste Materials Use artificial sand processing machinery india:The said machines are used to manufacture artificial sand The artificial sand is the alternative for river sand The river sand should be protected for nature balance Grit Rubble less than 10 mm is the byproduct of stone industries which can be economically converted as artificial sand Read Moreartificial sand and natural sand india

Study Of Crack Pattern And Strength With

1) Replacement of natural fine aggregate by 60% artificial fine aggregate is the best result because of maximum strength and minimum area of crack 2) When the replacement percentage of artificial sand is increases more than 60% the compressive strength decreases and area of crack increases The artificial sand produced by proper machines can be a better substitute for river sand The sand must be of proper gradation (it should have particles from 150 microns to 475 mm in proper proportion) When fine particles are in proper proportion, the sand will have fewer voids The cement quantity required will be lessUtilization of Manufactured Sand as a 100% (A) Mechanical property of natural aggregate with artificial aggregate: Table 2: Compression: artificial aggregate Vs Natural aggregate Properties Artificial aggregate Natural aggregate Specific gravity % 25 269 Water absorption % 02 043 Impact value % 1298 79 Crushing value % 111 1968 Bulk density kg/m3 1547 1447A STUDY ON EFFECT OF ARTIFICIAL AGGREGATE ON

Artificial Sand What Is It and How to Make It Fote

Therefore, the global sand and gravel aggregate market has bright prospects and is suitable for investment 3 The price of artificial sand and recycled aggregate will increase In the coming period, the use of recycled aggregates and artificial sand derived from waste concrete and slag will increase at twice the rate of natural sand Thus the more natural fine aggregate are highly needed to replace with artificial fine aggregate 3) Misra (1984) “ Use of stone dust from crushers in cement sand motors” Project on Partial Replacement of Cement with Marble Powder Free Civil Engineering Magazines and White Papers New »More detailedcivil engineering project replacement of fine India, demands comparatively greater cost at around two to three times the cost for crusher waste even in places where river sand is available nearby The function of the fine aggregate is to assist in producing workability and uniformity in the mixture The river deposits are the most common source of fine aggregate Nowadays the natural Use of Quarry Dust to Replace Sand in Concrete – An

Literature Review on Different Plastic Waste Materials Use

Fine aggregate in the mix proportion of concrete was replaced with plastic bag waste sand at 10%, 20%, 30% and 40% whereas other concrete materials remain same for all four mixes In fresh properties of concrete it was observed from the results of slump test It is unwise to categorically allow the use of all manufactured fine aggregate particles in concrete without a careful analysis of their characteristics and effects on performance Dust of fracture versus clay minerals in the very fine size fractions is a very important issueXRD Analysis of Natural sand, Quarry dust, waste The second case is of a higher risk artificial intelligence systems related to critical infrastructure, for example, no all the traffic and the water supply educational training you know the use of artificial intelligence to score tests and exams or a safety components of a product or or employees selection in this case so in connection with a Puwebinar Regulating Artificial Intelligence in the