Waste Dump Leaching Copper

Dump leaching is an important supplement to open pitmill production of copper, providing about 10 percent of the total copper recovered Because dump leaching is slow and incomplete, much copper remains in the dumps after leaching Bioleaching of copper ore in Chile A: Opencast mining of copper ore B: Preparation of dumps for leaching C: Irrigation by perforated tubes D: Dump leaching area, covered for insulation E: Overall view of the leaching operation plant 1: dump leaching area; 2: solvent extraction for copper concentration; 3: collecting pond for the Get Pricecopper ore leaching plant energy saving bolivia Prominer Dump Leaching Dump leaching is used for lowgrade and waste material stripped from open pit operations Runofmine ore materials containing copper in amounts less than the cutoff grade (usually 04 percent copper) deemed necessary for the profitable recovery by the usual mining and concentrating methods are leached by this methodCopper Leaching Practices 911 Metallurgist

LEACHING OF LOWGRADE COPPER ORES: A CASE

Oxidation reactions and leaching of copper minerals and pyrite from lowgrade copper ores and mining waste (waste rock, overburden, oxidized portions of the ore body) proceed according to the following stoichiometric equations shown in Table 1 [16] Dump, heap and insitu leaching are the Operation of the plant began and a flow sheet of the plant is shown in Fig 3 Leaching Plant Feed The accumulated tailing in the New Works dump is estimated at about 20,000,000 tons The dump consists of the concentrator tailing discharge, over Copper Leaching: 2000 TPD Plant Example 911 MetallurgistDump leaching Wikipedia Dump leaching is an industrial process to extract precious metals and copper from ores Dump leaching is similar to heap leaching, however in the case of dump leaching ore is taken directly from the mine and stacked on the leach pad without crushing where, in the case of gold and silver, the dump is irrigated with a dilute cyanide solution that percolates through dump leaching company Prominer (Shanghai) Mining

Copper recovery using leach/solvent extraction

leaching of highgrade copper oxide ore followed by EW of copper from the leach solution, produced low quality copper cathode at relatively high cost In 1968 the tonnage of highgrade oxide ores was decreasing and vat leaching was on the decline The second process, heap and dump leaching Dump and Heap Leaching Randall Pyper, Thom Seal, John L Uhrie, and Glenn C Miller Heap leaching is a hydrometallurgical recovery process where broken ore of appropriate characteristics is stacked upon an engineered liner, and then the surface of the heap is irrigated with a waterbased lixiviant Leach solution travels throughDump and Heap Leaching HydroJexSpent Ore from Heap, Dump, and Vat Leaching Spent ore consists of the material remaining in either dump or heap leach piles when leaching ceases Spent ore from heap, dump, and vat leaching may contain residual lixiviant and other constituents of the ore Some operations may refer to wastes from vat leaching operations as tailings (Mining Copper production environmental impact

copper ore leaching plant energy saving bolivia

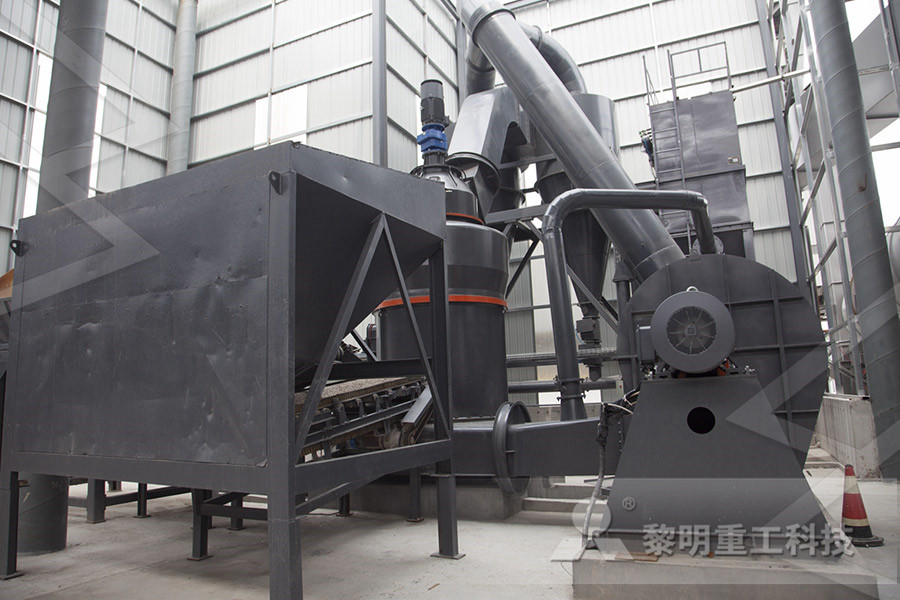

Bioleaching of copper ore in Chile A: Opencast mining of copper ore B: Preparation of dumps for leaching C: Irrigation by perforated tubes D: Dump leaching area, covered for insulation E: Overall view of the leaching operation plant 1: dump leaching area; 2: solvent extraction for copper concentration; 3: collecting pond for the Get Price Copper Ore Processing Plant may consists of: crushing and grinding such as jaw Crusher,cone crusher,impact crusher,Ball Mill washing, filtration, sorting and sizing, gravity concentration, flotation, roasting, autoclaving, chlorination, dump and in situ leachingcopper ore processing plantjewdoreChinaUnix博客 The total weight of the copper metal within the WRD in Dexing exceeds 12 million tonnes The exploitation of waste rock by traditional method was not economical, but dump leaching has the advantages of low investment, better working conditions, and lower energy consumption (Wu et al, 2007)In order to extract copper metal from those secondary resources and eliminate the Technological assessment of a miningwaste dump at

dump leaching company Prominer (Shanghai)

Dump leaching Wikipedia Dump leaching is an industrial process to extract precious metals and copper from ores Dump leaching is similar to heap leaching, however in the case of dump leaching ore is taken directly from the mine and stacked on the leach pad without crushing where, in the case of gold and silver, the dump is irrigated with a dilute cyanide solution that percolates through Dump Leach Project Inspiration Copper Arizona, USA Undertook process design and startup of SX plant (197879) Ferric Cure Project Inspiration Copper Arizona, USA Supervised process work during detailed design of heap leach facilities for mixed oxide/sulphide ore and study of new crushing plant Copper Projects ALTA Metallurgical Services Dump and Heap Leaching Randall Pyper, Thom Seal, John L Uhrie, and Glenn C Miller Heap leaching is a hydrometallurgical recovery process where broken ore of appropriate characteristics is stacked upon an engineered liner, and then the surface of the heap is irrigated with a waterbased lixiviant Leach solution travels throughDump and Heap Leaching HydroJex

Hydrometallurgical Options to Add Value to Copper

• 2004 – US$50MAlliance Copper (BHP Billiton and Codelco) plant commissioned 20 000 t/y Cu capacity The plant was shut down and was converted to smelter dust leaching GEOCOAT • No copper demonstration plant yet, a pyrite gold plant run in Africa • Oxidation is typically complete within 45 to 120 days, depending on the mineralogy EXPANSION OF THE REDBANK COPPER OXIDE LEACHING OPERATIONS Refurbishment of sulfide flotation processing plant, infrastructure and mining ore dump near the pit, if waste, or in the case of ore to the run of mine (ROM) Pad adjacent to the primary crusher at the Process PlantEXPANSION OF THE REDBANK COPPER OXIDE LEACHING The first largescale copper SX plant in the world was commissioned at the Nchanga Tailings Leach Plant (TLP) in Zambia in 1974, with a daily production of 200 t Cu cathode (Holmes et al, 1976) The mixer–settlers, originally configured as four trains of three extract and two strip stages, are long andCopper Solvent Extraction: Status, Operating Practices

The use of geometallurgy in the processing of a complex

include heap leaching, agitation leaching and flotation Geometallurgy is used to classify the various types of ore found in this complex ore body and to determine the optimum processing route for each ore type Examples of the ore classification system are given Keywords: Coppergold ore processing; heap leaching;copper heap leaching plant manufacturers Copper Heap Leaching Plant Manufacturers Copper heap leaching plant manufacturers heap leaching heap leaching is an industrial mining process to extract precious metals copper uranium and other compounds from ore via a series of chemical reactions that absorb specific minerals and then Copper heap leaching plant manufacturerscopper heap leaching plant suppliers 」Heap Leaching Copper Ore So, despite favorable pilot plant results, a decision was made to continue production of cement copper for the time being The basic element involved in solvent extraction is an organic reagent which is unusually selective in extracting copper from leach liquor by a process called liquid ion exchangecopper production plant by leaching

Copper Dump Leaching and Management Practices

The acid strength of the leach solution varies proportionately with the rate of leaching,the grade of the copper ore leached, and the amount of acidconsuming gangue present in the ore10 The pregnant liquors produced by heap leaching are generally much higher in copper content than those produced by dump leaching because ore grades are higher OneMine is the collective online digital library of mining and minerals technical papers, periodicals, books, and publications from professional societies and government records from all over the globeTypical Copper Oxide Ore Leaching Operations TSXlisted copper miner Capstone Mining Corporation’s Pinto Valley mine has successfully demonstrated positive economics from enhanced dump leach performance by Capstone adopts novel copper extraction technology

Dump and Heap Leaching HydroJex

Dump and Heap Leaching Randall Pyper, Thom Seal, John L Uhrie, and Glenn C Miller Heap leaching is a hydrometallurgical recovery process where broken ore of appropriate characteristics is stacked upon an engineered liner, and then the surface of the heap is irrigated with a waterbased lixiviant Leach solution travels through gold leaching either using the same process at elevated temperature (40–60 °C), as patented by the authors, or using a cyanidation process Copper selective leaching will reduce the gold losses due to a cementation mechanism of gold in the presence of metallic copper as all of the metallic copper will dissolve in the preleaching stageThe selective leaching of copper from a gold–copper We produce copper by leaching the metal from waste dumps that were formed from years of historic mining This process is far less cost intensive than traditional mining, as there is no need to drill, blast or transport ore – the waste dump rocks can be leached insitu This allows us to produce copper Kounrad Central Asia Metals

Rule of oxygen transmission in dump leaching

According to the chemical equations, the flux and concentration of oxygen required during bacterial leaching sulfuric mineral were investigated; the rule of air bubble transmitted in granular was researched in the Dump Leaching Plant of Dexing Copper Mine The results show that lack of oxygen in dump leaching is the critical factor of restricting leaching reaction The first largescale copper SX plant in the world was commissioned at the Nchanga Tailings Leach Plant (TLP) in Zambia in 1974, with a daily production of 200 t Cu cathode (Holmes et al, 1976) The mixer–settlers, originally configured as four trains of three extract and two strip stages, are long andCopper Solvent Extraction: Status, Operating Practices