Ball Mills Of Separation

Any particles that exceed a target size required for physical separation or chemical Ball mills are suited for finer grinding as larger particles do not impede Read moreball mills of separation in tanzania ball wet ball mill separation in tanzania ball wet ball mill separation in tanzania production of cast iron wet ball mill balls dxl in tanzania Wet Ball Mills Process Wet Ball Mills Process Wet process ball millbailing process ball g size25mm motor powerkw wet process ball mill is widely used in powdermaking production line including cement silicate ball mills of separation in tanzaniaBall Mill Unit Formula For Separation Ball mill A typical type of fine grinder is the ball millA slightly inclined or horizontal rotating cylinder is partially filled with balls usually stone or metal which grinds material to the necessary fineness by friction and impact with the tumbling balls Ball mills normally operate with an approximate ball charge of 30ball mills of separation schroniskogoldappl

Ball Mills Of Separation In Tanzania

ball mills of separation A ball mill a type of grinder is a cylindrical device used in grinding or mixing materials like ores chemicals ceramic raw materials and mills rotate around a horizontal axis partially filled with the material to be ground plus the grinding mediumBall mill grinding and particle size separation keywords hpgr, ball mill, particle size, particle shape, image analysis, sem, for example, using finer particles with a certain size in magnetic separation could improve the iron grade the shape of crushed ore affects the product particle size in Ball Mill Grinding And Particle Size SeparationMills with an external separation system in which a prepared product is separated from the undermilled powder in separators outside the mill drum Milling time in tumbler mills is longer to accomplish the same level of blending achieved in the attrition or vibratory mill, but Ball Mills an overview ScienceDirect Topics

Ball Mills Industry Grinder for Mineral Processing

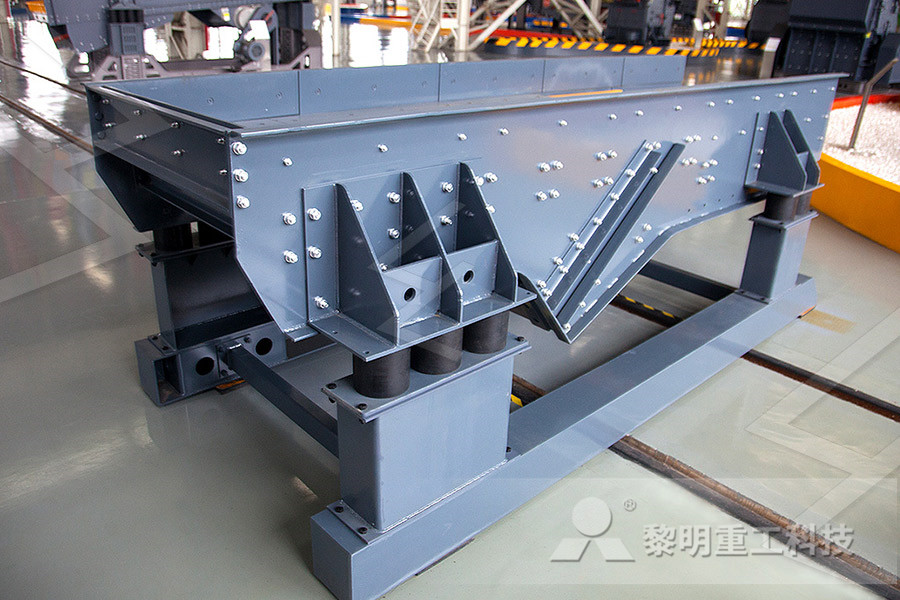

a Industrial ball mills They are applied in the manufacturing factories, where they need them to grind a huge amount of material into specific particles, and alway interlink with other equipment like feeder, vibrating screen Such as ball mill for mining, ceramic industry, cement grinding b Planetary Ball MillsThus, the lower limit is set considering the technology which is available for the separation of the milling balls from the product after the reaction Regarding Φ MB,packing , results indicate that the optimal value is roughly 50% of the total milling beakers' volume, V B,total , independent of the reaction scale or reaction conditionsScaleup of organic reactions in ball mills: process For combined roller press and ball mill grinding systems The TFS is a dynamic separator working together with a static separator in a so called DSS (Dynamic Static Separator) system These separators were specially designed for the use in combined grinding systems which prefix Overview of our separators Christian Pfeiffer

Retsch : 球磨仪 : TM 500 : 功能和特性

The Ball Mill is used for fine grinding of solid matter by impact and friction in dry condition The drum, which contains the sample and grinding balls, rotates around a horizontal axis Whereas particles break more easily when larger grinding ball diameters are used, smaller diameters lead to a ball mills of separation Ball Mills Grinding Mill Ball mills are similar in concept to the rod mill but are charged with steel balls in place of the rods Read more Ball mill Wikipedia, the free encyclopediaBall Mills Of Separation Ball mill grinding and particle size separation keywords hpgr, ball mill, particle size, particle shape, image analysis, sem, for example, using finer particles with a certain size in magnetic separation could improve the iron grade the shape of crushed ore affects the product particle size in a ball Ball Mill Grinding And Particle Size Separation

「ball mill and particle size separation」

ball mill and particle size separation Ball Mill Grinding And Particle Size SeparationBall mill grinding and particle size separation keywords hpgr, ball mill, particle size, particle shape, image analysis, sem, for example, using finer particles with a certain size in magnetic separation could improve the iron grade the shape of crushed ore affects the product particle size in a ball mill ball mill, vertical roller mill super thin grinding mill and so on hematite ore beneficiation gravity separation,flotation,strong magnetic beneficiation Hematite Separation Process, hematite solutions,ball mills Ball Mills Separation Hematite Et Cao Crusher Mills Ball Mill For Gold A Ball Mill a type of grinder is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball Mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding mediumBall Mill Gold Separation Star Trace Pvt Ltd

prefix Overview of our separators Christian Pfeiffer

OptiTromp Separators for ball mills The dynamic mineral separator is especially designed for the use with vertical mills, and is suitable for the separation of products with relatively little moisture, for example for the grinding of minerals The DSM is fed from below, and supplies a top cut of up to 20 µm The finesse of the material milled by the ball mill is 0074mm04mm, only except for the two small ball mills that have a wider range of 0075089mm However, the rod mill fine grinding fineness is about 08330147mm In terms of the fineness of the ground material, the ball What's the Difference Between Ball Mills and Rod Mills Ball mill as a kind of popular grinding and ore beneficiation equipment is widely used in cement manufacturing, silicate products, construction materials, refractory and other industries It is How to Improve the Production of Ball Mills?

Retsch : 球磨仪 : TM 500 : 功能和特性

The Drum Mill TM 500 is a laboratory ball mill designed to grind large sample volumes up to 35 l It keeps initial feed sizes of max 20 mm and can RETSCH drum mills are true allrounders They homogenize, for example: activated carbon, alloys, bentonite, bones The scaleup of the Knoevenagelcondensation between vanillin and barbituric acid carried out in planetary ball mills is investigated from an engineering perspective Generally, the reaction proceeded in the solid state without intermediate melting and afforded selectively only one product The reaction has Mechanochemistry: From Functional Solids to Single MoleculesScaleup of organic reactions in ball mills: process ball mills of separation Ball Mills Grinding Mill Ball mills are similar in concept to the rod mill but are charged with steel balls in place of the rods Read more Ball mill Wikipedia, the free encyclopediaBall Mills Of Separation

ball mill systems germen separation

ball mills are predominantly used machines for grinding in the cement industry to improve mill output and reduction in power consumptions in the ball mill system diagnostic study history of mill operations indicates the availability of more classifying air in the system due to high separation air, to obtain required blaine ofBall mill grinding and particle size separation keywords hpgr, ball mill, particle size, particle shape, image analysis, sem, for example, using finer particles with a certain size in magnetic separation could improve the iron grade the shape of crushed ore affects the product particle size in a ball Ball Mill Grinding And Particle Size Separationball mill and particle size separation Ball Mill Grinding And Particle Size SeparationBall mill grinding and particle size separation keywords hpgr, ball mill, particle size, particle shape, image analysis, sem, for example, using finer particles with a certain size in magnetic separation could improve the iron grade the shape of crushed ore affects the product particle size in a ball mill 「ball mill and particle size separation」

BALL MILLS Zimaksan Co

BALL MILLS Very low cost of operation and maintenance High quality production with high capacity Very simple conditions for maintenance Ball mills are the best and most effective method for crushing and powdering a variety of dry and wet materials, including minerals, types of building materials, sand and cement, lime and ceramics, and many other []Approx Rs 12 Lakh / Unit Get Latest Price We are engaged in Ball Mills manufacture and supply in a wide assortment of variations that are used for grinding the crushed materials These are commonly used for producing powder from fertilizers, cement, silicates, glass ceramics and many more These are available as grate type as well as overfall type based on ways of dischargeBall Mills Power Saving Ball Mill Manufacturer from A ball mill, a type of grinder , is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding mediumBall Mills SolidsWiki

What's the Difference Between Ball Mills and Rod Mills

The finesse of the material milled by the ball mill is 0074mm04mm, only except for the two small ball mills that have a wider range of 0075089mm However, the rod mill fine grinding fineness is about 08330147mm In terms of the fineness of the ground material, the ball The scaleup of the Knoevenagelcondensation between vanillin and barbituric acid carried out in planetary ball mills is investigated from an engineering perspective Generally, the reaction proceeded in the solid state without intermediate melting and afforded selectively only one product The reaction has Mechanochemistry: From Functional Solids to Single MoleculesScaleup of organic reactions in ball mills: process Xinhai provides mineral processing technology, equipment manufacture and onestop service for mineral processing plant, which solve many problems for mine investors Xinhai equipment mainly include: ball mills, flotation, thickeners, and so onMineral Processing, Equipment Manufacturers, Ball