design of classifier in vertical roller mills

Design Of Classifier In Vertical Roller Mills Design of classifier in vertical roller mills vertical classifier aerofall mills limited fig is a vertical sectional elevation of the classifier the vertical classifier shown in the drawings is intended to be used as a primary classifier in a mill system wherein coarse product is separated from an air stream in which it isdesign of classifier in vertical roller mills Design Advantages of Vertical Roller Mill Oil lubricating With the development of grinding mill, more and more machines have reasonable design, humanization manufacturing The vertical roller mill adopts the oil lubricating and it is very convenient to have the lubrication system , Wind speed and classifier can be adjusted and it candesign of classifier in vertical roller mill Atlas Vertical Roller Mill NETZSCH Mahlen The newly developed TC classifier and the Atlas roller mill bined for the production of fine and medium fine powders The innovative rotor design reduces energy consumption without losing its ability to produce sharp cut points The TC is an air stream classifier, which provides an excellent precision of cut at a very low pressure drop and is Vertical Roller Mill Classifier comprensivopievetorinait

static classifier of vertical roller al mill

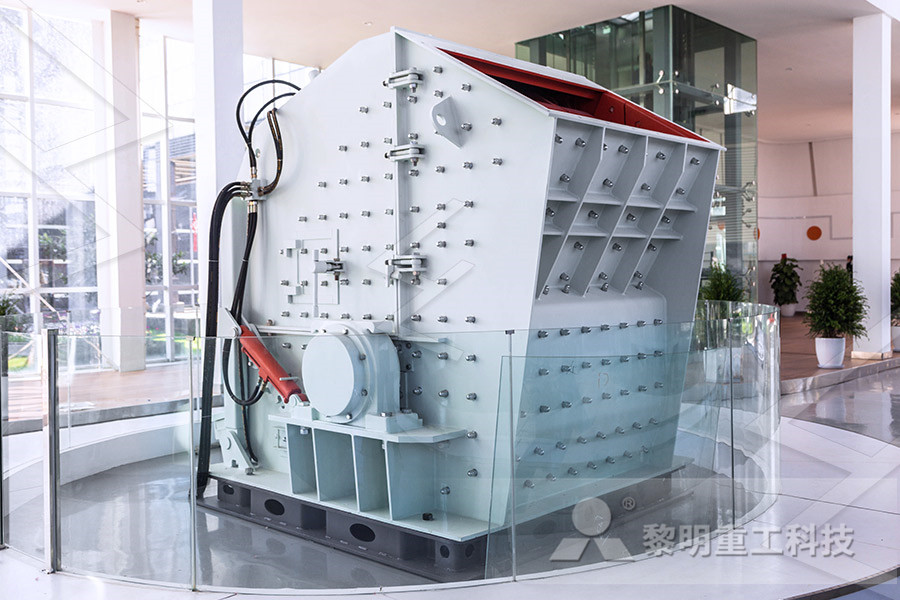

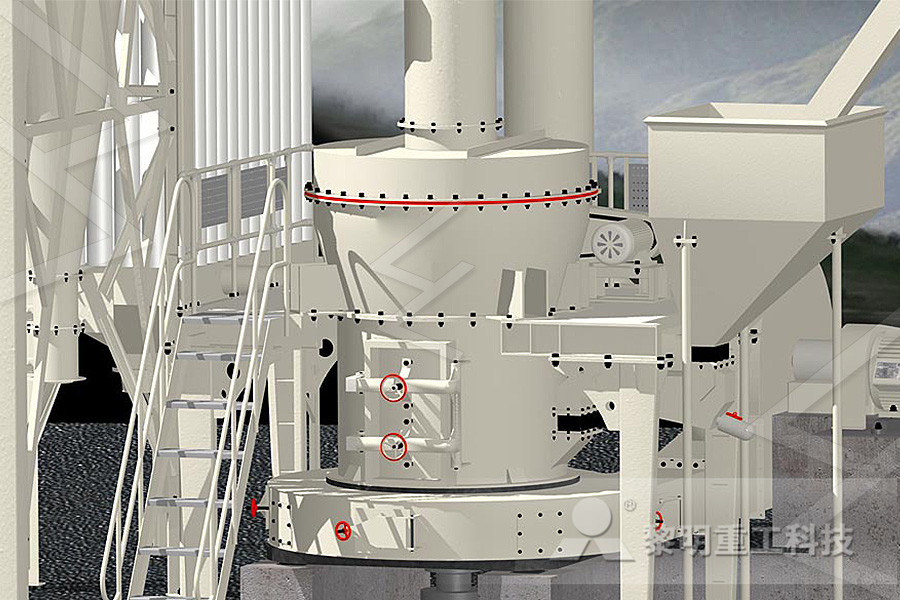

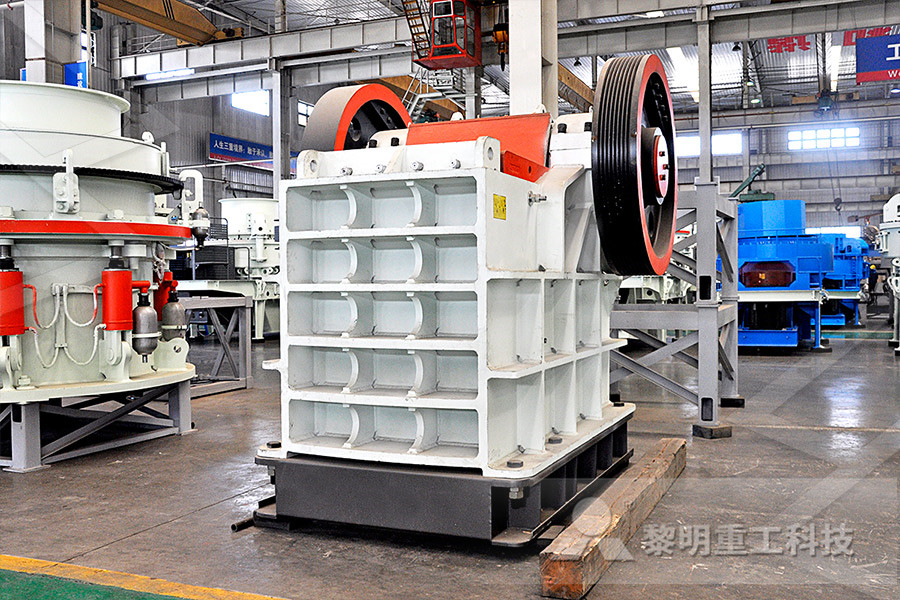

Vertical Roller Mill The vertical roller mill (VRM) shown in Figure 4 is an air swept, mediumspeed, vertical pulverizer with integral classifier It pulverizes coal by applying hydraulicallyloaded grinding pressure through three grin ding rollers onto a rotating bed of coal Grinding pressure can be adjusted to account for variations in coal More Classifier Vertical roller mill classifier is a part which is easy to be worn Classifier vane is used to avoid disqualified materials entering into the powder collector Under the function of wind, materials will move the powder collector through the classifierVertical Roller Mill Wear Parts Mill Roller Classifier Vertical Mill Separator Vertical Mill Rotor Mill Roller Overview We manufacture a wide range of mill roller that is widely preferred in the Indian textile industryMill Roller and Classifier partscasting

Vertical Roller Mill Great Wall

Structure of vertical roller mill 1) The combined classifier improves the powder selection efficiency 2) It is not necessary to distribute material on the grinding plate before startup The roller can be lifted up and down automatically and start without load 3) It is well sealed by welded arc plate and structure is simple and reliablecement vertical roller mill classifier Cement mills and raw mills for high throughput rates high drying capacity, short dwell time of the material to be ground, and remote control of grinding pressure and classifier rotor speed ensure a fully automatic operation of the mvr mill even with varying raw material characteristicsDifferent wear materials are used on our vertical roller millswhat is of vertical roller mill classifier Basic research and analysis, the development and design for MLS3626 efficient modular vertical roller Mill classifier Control key consideration regional component separator and particle motion, limiting the mill appear as irregular exercise, from the surface vertical roller Mill design principles and wearing parts repair

Dynamic Classifier Loesche

The high efficiency classifier can be used on LOESCHE vertical roller mills and also for all air swept grinding mills The classifier is designed for central or without central material feed and can be used for all materials to be groundVertical air classifier mill/ roller mill/grinding mill is designed by our RD department on the basis of multiple innovation and testing It has been proved by thousands of customers that our machine has outstanding features, stable quality, easy operation and maintenanceIt is the ideal equipment for Vertical Air Classifier Mill/ Roller Mill/grinding Mill Vertical roller mill for raw Application p rocess materials compared with tube mills These days, the vertical roller mills have been widely adopted A)Structure (1) The rollers are hydraulically pressed against a disc table and the feed is ground between the rollers and the disc table (2) The classifier is housed above thewhat is of vertical roller mill classifier

static classifier of vertical roller al mill

Vertical Roller Mill The vertical roller mill (VRM) shown in Figure 4 is an air swept, mediumspeed, vertical pulverizer with integral classifier It pulverizes coal by applying hydraulicallyloaded grinding pressure through three grin ding rollers onto a rotating bed of coal Ultra fine powder vertical roller mill is the cement industry, coal industry, power sector and other widely used grinding machine, with the breaking, crushing, grinding, powder and drying in one and so on Ultra fine powder vertical roller mill for raw material and preparation of coal over half a century of history On the vertical roller mill and working principle of the structural features of maUltra Fine Powder Vertical Roller Mill Classifier System Mill Roller Classifier Vertical Mill Separator Vertical Mill Rotor Mill Roller Overview We manufacture a wide range of mill roller that is widely preferred in the Indian textile industry Our range of mill roller is manufactured under strict ISO 9001:2000 quality guidelines to ensure unmatched quality and performance We conduct a thorough Mill Roller and Classifier partscasting

Vertical Roller Mill Great Wall

Structure of vertical roller mill 1) The combined classifier improves the powder selection efficiency 2) It is not necessary to distribute material on the grinding plate before startup The roller can be lifted up and down automatically and start without load 3) It is well sealed by welded arc plate and structure is simple and reliable In the airswept mode, the verticalrollermill and a high efficiency dynamic classifier are suited above each other as a single unit Material is fed to the grinding chamber and transported by table rotation to the grinding gap between the fixed grinding rollers and the mill tableOperational parameters affecting the vertical roller The high efficiency classifier can be used on LOESCHE vertical roller mills and also for all air swept grinding mills The classifier is designed for central or without central material feed and can be used for all materials to be groundDynamic Classifier Loesche

Windsifter Air Classifiers Bradley Pulverizer Company

The Vertical Blade Classifier (VBC) technology incorporated into the Bradley Windsifter Air Classifier utilizes vertical oriented blades and the separator rotor to create a vortex, spinning the air and throwing the coarse particles out to the sides, where they fall for bagging LUM series vertical roller mill mainly powder selecting machine, roll grinder, grinding disc device, pressure device, reducer, motor, shell and other components The separator is a kind of high efficient, energysaving powder selecting devicevertical roller mill working principlecongcheng7001的博客 Vertical Roller Mill The vertical roller mill (VRM) shown in Figure 4 is an air swept, mediumspeed, vertical pulverizer with integral classifier It pulverizes coal by applying hydraulicallyloaded grinding pressure through three grin ding rollers onto a rotating bed of coalstatic classifier of vertical roller al mill

classifier used in vertical roller mill

JPHA Classifier for vertical roller mill Google PURPOSE:To keep the accuracy of classification high and to effectively produce products stable in particle size in a classifier for a vertical roller mill for pulverizing coal, limestone, etc CONSTITUTION:To the outer peripheral end part of upper support plates 9a of classifying blades 10, of a rotary classifier incorporated in an Basic research and analysis, the development and design for MLS3626 efficient modular vertical roller Mill classifier Control key consideration regional component separator and particle motion, limiting the mill appear as irregular exercise, from the surface vertical roller Mill design principles and wearing parts repair The Bradley Vertical Blade Classifier (VBC) is designed to separate extremely fine powders direct from any airswept mill Dynamic classifiers such as the VBC, provide wide flexibility of operation by allowing for instant adjustment of particle separation rangesVertical Blade Classifiers (VBC) Bradley Pulverizer

FL/ITC Vertical Air Classifier Air Classifier ALPA

In conjunction with ball mill, table roller mill and Raymond mill to form closed circulation The motor can be connected with a belt, which is stable and reliable, realizes high speed and increases the speed, and breaks through the problem that the wellknown motor brand does not have a highspeed motor FL/ITC Vertical Air Classifier I claim: 1 A dynamic roller mill air classifier with an integrated air classifier for a rising gasgrinding material flow located above a roller mill, with a classifier rotor having roughly vertical classifying ledges, said classifier from the flow standpoint is followed by at least one gas flow outlet and a fine material outlet, as well as at least one coarse material return, with a mill Dynamic roller mill air classifier Loesche GmbHBecause the BLVT classifier can be installed or retrofitted on any airswept mill, including pendulum roller mills, vertical roller mills and ball mills, it creates a quick payback period and high return on investmentBLVT Classifiers Bradley Pulverizer Company

Review on vertical roller mill in cement industry its

The raw mill is either a Ball mill with two chambers or Vertical roller mill with inbuilt classifier The hot gases from the pre heater enter the mill and are used for drying material in the mills The ball mill and VRM are explained in further sections of this thesis The hot gas and dry fine ground material are fed to the mill outlet to a NETZSCH Ecutec's Atlas Vertical Roller Mills has been developed for more efficient fine grinding of soft to mediumhard materials The Atlas is a roller airswept mill designed for continuous operation with minimum maintenance The fundamental difference between the Atlas and other tableroller mills is the bearing arrangement for the grinding table, which is incorporated into the base of the Atlas Vertical Roller Mill NETZSCH Grinding Toll air classification services and manufacturer of air classifiers, ball mills and stirred media mills for the production of fine, superfine and ultrafine powders for the mineral, mining, cement, lime, metal powder and chemical industriesBall Mills Air Classification United States