size of cement mill mrtdegroeinl

re Cement Mill Diaphragm Slots size In a conventional closed circuit ball mill,to prevent the clinker nibs entering to second chamber of the ball mill, first chamber slot size has been kept 68 mm by different manufactureSecond chamber diapharagm slot size has been kept 810mmPolysius mill designer also follows the same industrial design normssize of cement mill fcknabbebe On the Reconstruction of Size 32×13m of Cement Mill HU Gang (Nanning Heavy Mach mill,this paper introduced the measures and methods to raise output of cement , and to r; Cement clinker mill could be the main equipment in cement mill or cement clinker proces Two, should strictly control of the grain sizesize and function of cement mill beaumontbaladesfrBall Mill Calculation For Cement Plant Calculate top ball size of grinding media equation method early in the twentieth century, ball mill manufacturers and other research laboratories developed proprietary batchgrinding tests to measure the resistance of metallic mineral ores, industrial mineral ores, cement raw materials, cement clinkers, and related materials being ground to fine sizes in how to calculate size of ball mill in cement plant

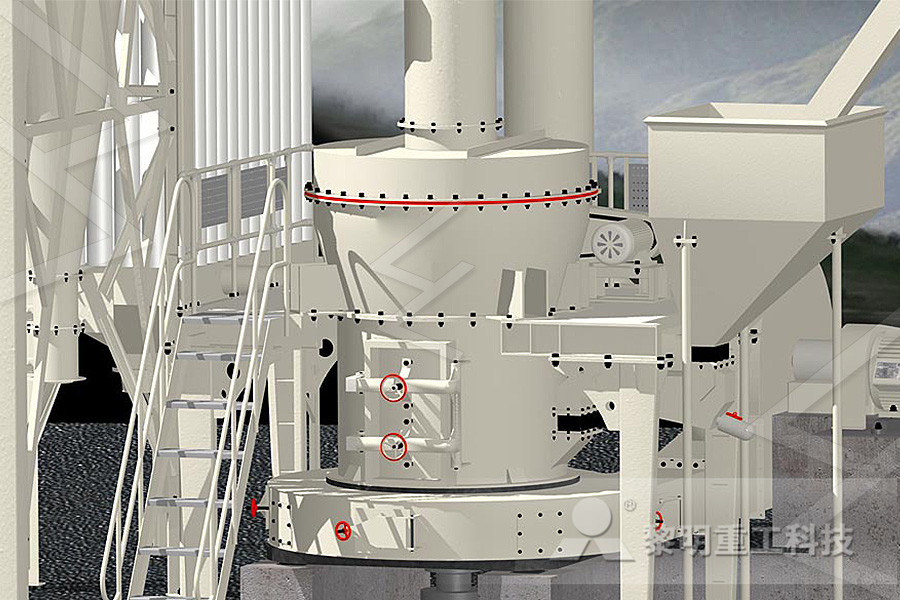

Cement Mill Dal Technic Machinery A Company of

Cement Mill UNIVERSAL DRIVE BALL MILLS UDCM type mills are designed to achieve maximum grinding efficiency, low energy consumption, compact plant layout and compact mill drive design large grinding media for coarse grinding and special lines ensures optimum lifting of the mill charge The size distribution of the grinding media in the The cement ball mill in cement plant is usually divided into 24 silos, the most representative of which are the “new type of high fineness cement ball mill” and “open flow high fineness cement ball mill” There are three cement processing circuits 1 Open circuit grinding The ball mill in the cement plant for open circuit grinding consists of grinding bin, dust collector and ball millCement Ball Mill JXSC Machine The finish mill system in cement manufacturing is the second to last major stage in the process, where the feed material is reduced in size from as large as several centimeters in Cement Finish Milling (Part 1: Introduction amp;

Cement grinding Vertical roller mills versus ball mills

serious challenge to obtain a good performance of a vertical roller mill in cement grinding Today, however, the OK mill has become an excellent example of a mill design that has overcome the difficult grinding conditions associated with finish grinding of cement clinker and related products The OK mill was developed by Onoda Cement Co, Onoda Engineering and Consulting Co and Kobe Steel in A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Monitoring fineness of raw meal and cement by grain size distribution Reliable analysis of grain size distribution within seconds with laser diffraction and dry dispersion Continuous and prompt control during grinding and screening guarantees stable product quality, avoids Cement Particle Size Analysis Sympatec

VRM vs Ball Mill for Cement Grinding Page 1 of 1

Reliability Product quality good partcicle size distribution in ball mill as we can play wtth Grinding media filling VRM has less flexibility in controlling particle size distribution Overall ball miil is good option for Cement mill but only has limitations for higher capacity, as two ball mill to be installed for One VRM, but in case of breakdown one ball mill can be in operationsize and function of cement mill size and function of cement mill studiobeikircherit Mill Function In Cement Industry Mill Function In Cement Industry Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal size and function of cement mill beaumontbaladesfrVRM vs Ball Mill for Cement Grinding Page 1 of 1 Feb 10, 2016 Mill(300350 TPH) and before implementing the project, we would like to gather as much information regarding the actual operation of this mill during cement grinding and the quality of the product in terms of the fineness/particle size distribution and how does it compare with the product of a ball mill relative to these parameters Cement Mill Particle Size Distribution

Cement Mill Particle Size Distribution laneyogade

cement mill particle size distribution elkesfewode in the cement industry the shape of such particle size distributions is commonly modelled using the rosin rammler distribution function where r x is the retained at size x, x c is a characteristic size, and s is the quotslopequotcement mill particle size distributioncement millBall mill has been used in many industries for a long time, the technology is quite LM Vertical Roller Mill Vertical Roller Mill is our newlylaunched product which is applied as a solutionmobile stone mining mill, small size cement mill The size combination options in the table above shows how 4 and 6 roller mills exploit the advantages of common features across different mill sizes for cement and raw applicationsOK™ mill The most reliable and efficient mill for raw and

Cement Mill Diaphragm Slots Size

Cement Mill Diaphragm Slots Size Cement Mill Oleh M Choirun Nasirin Riski Arif Maulana Grinding system Tube mill adalah alat yang digunakan untuk menghaluskan semen dengan menggunakan bola besi ball sebagai media penggilingan 2 Holcim Academy Mill Operator Excellence Separatorsppt System Operation in Tube Mill Open Circuit System Merupakan tipe sirkuit lama yg Some cement groups use a formula, such as Bond’s, to calculate the maximum ball size required in a ball mill, based on the average size of the clinker feed However, one drawback with this approach is that in some cases the formula will result in the prediction that 100mm balls be used to deal with large clinker particlesClinker size and cement grinding GCP Applied Mill size 46 x 165 m L/D ratio Mill drive 358 5000 kW Diaphragm Double blind plate Mill speed 152 rpm GM in I chamber 107 t Critical speed 76 % GM in II chamber 217 t • The cement mill and the sepax separator were thoroughly inspected to observe internal condition of the mill and separator During the inspection, mill and separator PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

1 cement mill ppt Mill (Grinding) Cement

Water Injection into The Mill 51 General • Water injection • Control cement temperature within the mill • Prevent gypsum dehydration At any place within or after the mill To restrict false set and lump formation in silos To reduce loss of strength properties To reduce workability problems of the cement 52 Water Injection The particle size of Class G oilwell cement is responsible for its limiteduse in specific remedial cementing operations Because the largest particles ina typical Class G cement are in the 100 to 150 range, cement slurries willnot penetrate fractures narrower than about 04 mm or sandpacks finer thanabout 10/20 meshSmallParticleSize Cement SPE Production VRM vs Ball Mill for Cement Grinding Page 1 of 1 Feb 10, 2016 Mill(300350 TPH) and before implementing the project, we would like to gather as much information regarding the actual operation of this mill during cement grinding and the quality of the product in terms of the fineness/particle size distribution and how does it compare with the product of a ball mill relative to these parameters Cement Mill Particle Size Distribution

Cement Mill for Sale Buy Cement Ball Mill Vertical

Cement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders Cement ball mill and vertical roller mill are two most widely used cement mills in today’s cement grinding plants and are also the main types of cement mill we produce As a professional cement equipment manufacturer, AGICO has rich experience in the designing and manufacturing of cement mill particle size distribution elkesfewode in the cement industry the shape of such particle size distributions is commonly modelled using the rosin rammler distribution function where r x is the retained at size x, x c is a characteristic size, and s is the quotslopequotcement mill particle size distributioncement millCement Mill Particle Size Distribution laneyogadeCement grinding ball mill particle size reduction cement mill wikipedia cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementost cement is currently More Ball Mill Balls on sales Quality Ball Mill Balls suppliercement grinding ball mill ball size MC WorldINC

OK™ mill The most reliable and efficient mill for raw and

The size combination options in the table above shows how 4 and 6 roller mills exploit the advantages of common features across different mill sizes for cement and raw applications Cement Mill Diaphragm Slots Size Cement Mill Oleh M Choirun Nasirin Riski Arif Maulana Grinding system Tube mill adalah alat yang digunakan untuk menghaluskan semen dengan menggunakan bola besi ball sebagai media penggilingan 2 Holcim Academy Mill Operator Excellence Separatorsppt System Operation in Tube Mill Open Circuit System Merupakan tipe sirkuit lama yg Cement Mill Diaphragm Slots Size finish grinding of Portland cement, slag and blended cements The mill consistently uses five to ten percent less power than other cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the OK cement mill is 3045 percent lower for cement grinding and 4050 percent lower for slagOK™ cement mill The most energy efficient mill for

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

Mill size 46 x 165 m L/D ratio Mill drive 358 5000 kW Diaphragm Double blind plate Mill speed 152 rpm GM in I chamber 107 t Critical speed 76 % GM in II chamber 217 t • The cement mill and the sepax separator were thoroughly inspected to observe internal condition of the mill and separator During the inspection, mill and separator Water Injection into The Mill 51 General • Water injection • Control cement temperature within the mill • Prevent gypsum dehydration At any place within or after the mill To restrict false set and lump formation in silos To reduce loss of strength properties To reduce workability problems of the cement 52 Water Injection 1 cement mill ppt Mill (Grinding) Cement The particle size of Class G oilwell cement is responsible for its limiteduse in specific remedial cementing operations Because the largest particles ina typical Class G cement are in the 100 to 150 range, cement slurries willnot penetrate fractures narrower than about 04 mm or sandpacks finer thanabout 10/20 meshSmallParticleSize Cement SPE Production