Improved dust capture methods for crushing plant

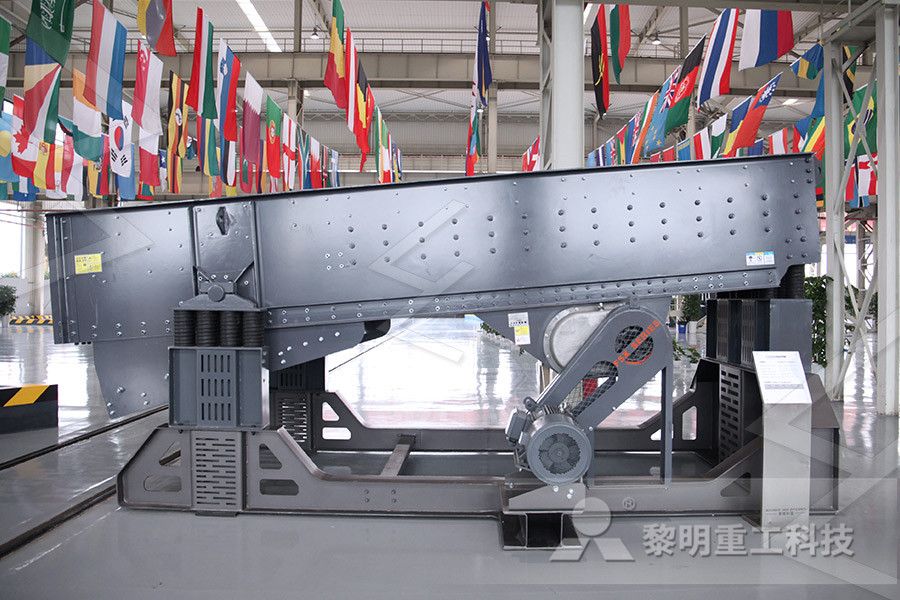

During gyratory crushing operations dust is released during the tipping process when material is dropped from the raised bed of trucks into the crusher feed bin The large volume of material dropped during any one tipping event, which may range between 50 and 100 tonnes, can result in a large and sudden displacement of airThe use of compressive crushing equipment such as gyratory crushers within minerals processing plants can potentially generate large quantities of dust Remedies to this problem include the retrofitting of shrouds, enclosures, local exhaust ventilation (LEV) systems and water suppression systemsImproved dust capture methods for crushing plant methodology dust contole of crusher plant dust controlsystem oncrusherand screens areadust controlsystems in stonecrusher plantsdust controlforcrusher plantDustis generated during the workingprocesswhile thedust controlunits are neededcrushing plantis mainly composed with vibrating feeder, jawcrusher, conecrusher/ impactcrusher, vibrating screen, belt conveyor and electrical methodology dust contole of crusher plant ataFinch

Dust Free Crushing Plant androidhubode

How to reduce dust in your crusher plant Improved dust capture methods for crushing plant improved dust capture methods for crushing plant whilst material wetting and suppression sprays have been proven to reduce airborne dust levels these measures often create adverse working conditions in terms of water settlement and collection on the haul roads in the vicinity of the crusher and an increase in airborne Crushing Misting cannons throw mist above the crusher to help bring down rising dust and create a barrier Transporting Misting cannons help reduce dust in the loading and unloading process Smaller misting bars, like the DBM Mini, help prevent fugitive dust when transporting with conveyor belts by supplying mist at their discharge pointsDust Control Misting Cannons and Applications targeting crusher dust The primary target for improving dust suppression at TCL was the mobile crushing unit The company uses one of the largest tractor rippers Dust control at limestone quarry BossTek

Foam for Dust Control 911 Metallurgist

Crusher Dust sampling on the crusher was performed at two locations, the operator’s position and a location of suspected high dust concentration on a walkway midpoint between the operator and the crusher At each location the RAMI monitored Observe crusher in use and note where any dust is escaping Check the extraction points have sufficient draw Could the dust capture be improved? Check the sample collection box below the crusher is closely fitted to the outlet to minimise dust escape 33 Dust is controlled duringSurface dust management audit guide Dust emissions arising from construction activities can cause nuisance both within the site and outside the site boundary (Table 11) Within the site, dust can cause mechanical or electrical faults to equipment, such as computers, and will increase abrasion of moving parts in plant and clogging of filters In the surrounding environment, it Control of dust from construction and demolition activities

dust extraction for cone crusher

Dust extraction unit, yes China Dust Crusher Wholesale Alibaba offers 11,809 dust crusher products About 4% of these are crusher, 1% are plastic crushing machines A wide variety of dust crusher options are available to you, such as jaw crusher, roller crusher, and impact crusher Weight And Dimension Cage 160x6 60mm Crusher Dust ExtractionManaging Fugitive Dust State of Michigan the study area is in and around Balasore town where several stone crusher units are problems to monitor the dust pollution level 5 monitoring stations were Hazard Prevention and Control in the Work Environment: Airborne Dust eruption, and by mechanical or manmade processes such as crushing, grinding crusher stone fugitive dust crusher manufacturer, model no, serial no, date of manufacture (required for determining applicability of federal NSPS Subpart OOO 40 CFR §60670) While the regulation presumes that a dust capture system venting to an emission control device will be used, wet suppression systems that either prevent the dust from being generated or that Gravel Pits, Quarries, and Aggregate Crushing and

Dust Mitigation in Geochemical Sample Preparation

crusher, and hatches on the side and front to allow access to the disk mill We use a HEPAfiltered vacuum to capture dust from the jaw and disk mill during cleaning between samples If you want, I can send you pics of our installation We do not require operators of the crushing facility to use dusk Dust areThe RotoClone® W is the most cost effective, highefficiency wet dust collector in its class Combining a dust collector with a centrifugal fan, saving space and enhancing its suitable for a wide variety of different applications The distinguishing feature of the RotoClone® W is the addition of a fine water film on the impeller blades to capture even the smallest of dust particlesWet Dust Collectors AAF InternationalDust needs to be effectively controlled at each crusher, mill and grinder, with dust control appliances fitted at the primary crusher feed hopper as well as secondary and tertiary crushers plus screens Conveyor belt transfer points and stockpile tunnels may also require dust control measuresGuidance about dusts and other airborne contaminants

A Practical Guide to Dust Suppression Sealpump

capture or control airborne dust may be required at conveyor transfer points The first consideration is whether the volume of dust generated can be reduced Although it is unlikely that dust can be completely eliminated, a change in system design or production technique will minimise the amount of dust produced capture velocity in the hood was set by adjusting the variable speed DC motor of the tubeaxial fan installed on the hood outlet duct The hood capture velocity was selected based on observations of the fugitive dust capture characteristics of the hood This testing approach is an adaptation of theref # 3 PM10 Emission Factors for a Stone Crushing Plant REMIN volcanic rock dust is a CARBON CAPTURE product developed in collaboration with Newcastle University ONE TONNE of REMIN applied to soil removes Remin (Scotland) Ltd leading provider of volcanic

Spiritfarer Items Guide: Every Important Item and How

The world of Spiritfarer is vast and full of nifty items to collect Some are only good for making extra Glims — Spiritfarer's currency — while others are vital resources you'll need to upgrade your ship and help ease your passengers into the beyondWe're rounding up every Spiritfarer item, where to find these items, and what they do to help make your own journey smootherImproved dust capture methods for crushing plant Dust Removal Measures At The Working Site Of The Crusher 14 38 31 Generally speaking the crusher will be set with similar active start and stop control effects and a central silo This level control is divided into three types front control rearCrusher dust removal measures melodysafariscozaImproved dust capture methods for crushing plant A local exhaust ventilation (LEV) extraction ducting is currently installed as an additional measure to remove airborne dust These systems are installed above or in the vicinity of the crusher feed bin Crusher Dust Systems HeNan Mining Heavy Industries Co, Ltd Dust suppression system for dust extraction systems for crusher hotelcelanoit

Dust Control Misting Cannons and Applications

Effective Dust Control Misting cannons are the best option for dust control due to the use of tiny water droplets that drop dust to the ground DustBoss equipment uses atomized mist in the 50 200 micron range to capture dust This range is the ideal size for dust control as the water droplets avoid the slipstream effect12 The process of claim 1, further comprising: crushing the solid material in a crusher device to form the dust material; collecting the dust material from the crusher device in a second particulate capture device; and pneumatically transferring the dust material from the second particulate capture PLENUM CRUSHER DUST INJECTION Solvay crusher manufacturer, model no, serial no, date of manufacture (required for determining applicability of federal NSPS Subpart OOO 40 CFR §60670) While the regulation presumes that a dust capture system venting to an emission control device will be used, wet suppression systems that either prevent the dust from being generated or that Gravel Pits, Quarries, and Aggregate Crushing and

Dust Mitigation in Geochemical Sample Preparation

crusher, and hatches on the side and front to allow access to the disk mill We use a HEPAfiltered vacuum to capture dust from the jaw and disk mill during cleaning between samples If you want, I can send you pics of our installation We do not require operators of the crushing facility to use dusk Dust are We just turned it on and let it oscillate whenever we were moving material to or from the crusher" Ken Sidwell VP Highpowered dust suppression has proven to be a key element in the onsite processing of waste concrete and block into usable aggregate during the demolition of a former signage shop previously owned by the Illinois DOTDemolition Dust Control: From Hoses to Dust Control animation crusher capture Brian the Robotwas the primary mascot of Confused, replacing Cara Confused in May 2013 and he was gone in 2016 He is a robot determined to help people save money on their insurance According to Confused, he is the fastest insurance comparison robot in the world 1 Appearance 2 Advertising 21 The Simpsons animation crusher capture ataFinch

A Practical Guide to Dust Suppression Sealpump

capture or control airborne dust may be required at conveyor transfer points The first consideration is whether the volume of dust generated can be reduced Although it is unlikely that dust can be completely eliminated, a change in system design or production technique will minimise the amount of dust produced Dust emissions arising from construction activities can cause nuisance both within the site and outside the site boundary (Table 11) Within the site, dust can cause mechanical or electrical faults to equipment, such as computers, and will increase abrasion of moving parts in plant and clogging of filters In the surrounding environment, it Control of dust from construction and demolition activities