Beneficiation Rod Mill Weight wegielkapalapl

beneficiation rod mill weight beneficiation SGS New ZealandBeneficiation is the process where ore is reduced in size and The Bond Rod Mill Grindability Test is Get Price Hematite Beneficiation Process Plant With Cone CrushersRod Mill Model Barrel size(mm) Effective volume (m3) Bar weight(T) Rotating speed(r/min) Power(KW) Discharge size(mm) Capacity(t/h) Weight(T) MB0924 31: 29: 22: 2502: 2910: 66: MB1224 65: 27: 37: 2502: 513: 135: MB1530: 5: 8: 23: 75: 2502: 5512: 1671: MB1830: 65: 17: 228: 130: 2502: 9520: 298: MB2136: 11: 28: 209: 210: 2502: 14835: 494: MB2436: 146: 37: 19: 280: 2502: Rod Mill Introduction,Rod Mill Working Principle MBS Type Rod Mill Production Capacity:062180t/h Feed size:≤50mm Processing Materials: Quartz stone, iron ore, copper ore, gold ore, cement clinker, pyrrhotite, hematite, limonite, construction waste and so on View More Get Quotes Beneficiation EquipmentBeneficiation EquipmentFote Machinery sinoftm

MBS Type Rod MillFote Machinery sinoftm

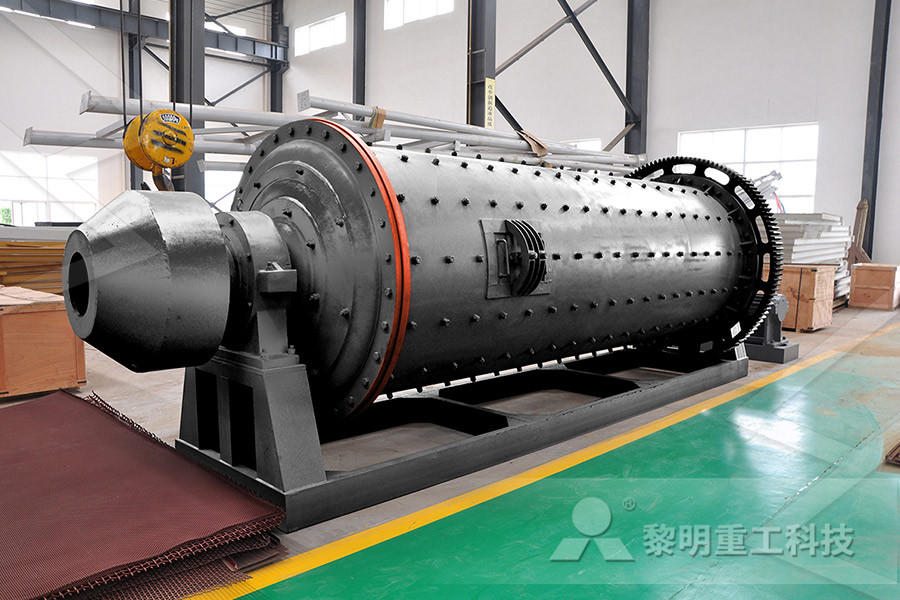

MBS Type Rod Mill Beneficiation Equipment For coarse grinding, the processing amount of rod mill is greater than ball mill with the same specification, and vice versa Applicable materials: Quartz stone, iron ore, copper ore, gold ore, cement clinker, pyrrhotite, hematite, limonite, construction waste 062180t/h Production Capacity ≤50mm Feed size With low medium filling rate of about 35%—40%, the rotary rate of the wet type rod mill is low and the common rate is between 60%—70% The steel barrel will be distorted when rotating if the feed size is too large At the same time, there will be larger space between the barrels and this will cause the decline of productionMBS Rod Mill cement mill,ball mill,rotary kiln,cement 11 行 Rod mill is widely used grinding machine to grind all kinds of ore and rocks in Rod MillMBS Rod millRod Grinding MillCrushing Mill

Wet rod mill Yantai Jinpeng Mining equipment, ore

Wet rod mill: Model: barrel: Motor: Boundary dimension(mm) Effective volume(m3) Max loading ball(t) Weight(kg) diameter(mm) length(mm) Model: Power(kw)speed(r/min(length: width: height: MBY 0918: 900: 1800: Y225M8: 22: 730: 4980: 2370: 2020: 062~32: 09: 5700: MBY 0924: 900: 2400: Y250M8: 30: 730: 5670: 3280: 2020: 081~43: 12: 5880: MBY 1224: 1200: 2400: Y280M8: 45: 730: 6450: When you install the rotary part of the rotary rod mill, you should pay attention to the following points First, before assembling the cylinder and the hollow shaft, you should check the barrel The ovality tolerance should not be greater than 5 mmRotary Rod Mill,Rod Grinder,Pin Crusher video Bond Rod Mill Grindability Test The test determines the Bond Rod Mill Work Index which is used with Bond’s Third Theory of Comminution to calculate net power requirements when sizing ball mills* Various correction factors may have to be applied The test is a closedcircuit dry grindability test performed in a standard rod millBond Tests SGS

(PDF) THE BENEFICIATION OF GRAPHITE BY

Percentage Purity (% P) = (Bradshaw, 2005) Percentage Ash Content (% AC) = (Crozier, 2004) Where: W1= initial weight and W2 = final weight RESULTS AND DISCUSSION Table 2: Beneficiation of Graphite Using Oleic Acid and Soybeans Oil as Collectors Sample Collector Weight of Weight of (g) Concentrate (g) Tailings (g) 300 Oleic acid 1314 1684 300 Soya beans oil 1290 1708 Source: Nuhu, S K Product Model: Various specificiations for choice Production capacity: 062180t/h Material: Coal, cement, ore, calcite, cement clinker, dolomite, clay, coal, barite, and gypsum,etc MBS Rod mills have two types dry type rod mill and wet type rod mill It uses the advanced technology of controlled feeding and discharging, equip with suitable grinding body according to the actual grinding materialMBS Rod Mill cement mill,ball mill,rotary kiln,cement Rod mill is one kind of grinding machine and named after the grinding mediasteel rod and generally wet type rod mill is preferable Rod mill can be used as primary opencircuit grinding machine and widely used as primary mill in electrical apartment in artificial sand making, ore beneficiation plant, and chemical plantRod MillMBS Rod millRod Grinding MillCrushing Mill

Rod Mill Haiwang Technology Group

2 The use of advanced control access to material rod mill technology, combined with the actual users’ abrasive material to cutters with the appropriate grinding , ball mill is changed the traditional surface contact to line contact, making machine more uniform, higher yields ,and be used in different hardness (Mohs hardness of 55 to 12) of ore Rod mill gets its name because its grinding body inside the barrel is steel bar Rod grinding mill, as firstclass ore grinding machine, is widely used in the first class grinding in industries such as artificial sand, ore beneficiation plant and power sector in chemical plantRod Mill,Grinding Rod Mill,Rod Grinding Mill Hxjq From the bin it was transferred by a constantweight feeder to a rod mill operated at 60 percent solids The rod mill operated in closed circuit with a vibrating screen to grind the ore to minus 65 mesh The screen undersize (minus 65mesh) passed to a hydroseparator for removal of colloidal slimes The hydroseparator overflow represented Fluorspar Beneficiation Process Plant

ball mill for beneficiation industry Prominer

mining ball mill Beneficiation Equipment There are five typical ball mills in : 1Mining Ball Mill 2Coal Mill 3Raw Mill 4Cement Mill 5Rod Mill These different types of ball mill are applied into cement industry, mining industry, building material, chemical industry etc As the mill turns, the rods cascade over each other in relatively parallel fashion One of the primary advantages of a rod mill is that it prevents overgrinding of softer particles because coarser particles act as bridges and preferentially take the compressive forces Rod mills can take particles as Introduction to Mineral Processing or BeneficiationBond Rod Mill Grindability Test The test determines the Bond Rod Mill Work Index which is used with Bond’s Third Theory of Comminution to calculate net power requirements when sizing ball mills* Various correction factors may have to be applied The test is a closedcircuit dry grindability test performed in a standard rod millBond Tests SGS

Chromite Beneficiation Process 911 Metallurgist

A rod mill with the peripheral discharge feature is preferred for this application because the ‘”rapidpass” design produces a minimum of the undesirable fines The discharge from the rod mill returns to the Dillon Vibrating Screen by means of a Belt Bucket Elevator, so that a closed circuit grinding arrangement is obtainedThe equipment consists of a rotating drum into which dry ore samples are placed, with an impact paddle mounted on a centre shaft rotating at a higher speed than the drum The paddle is made from standard alloy steel hardened to 500 Brinell The Abrasion Index is determined from the weight loss of the paddle under standard operating conditionsAbrasion Test SGS The rod mill for beneficiation is loaded with the grinding media of steel rods It consists of five parts including cylinder shell, feeding system, discharge system, main bearing and transmission system The beneficiation machinery is available for both of the dry grinding and wet grinding fashion as the customer’s needsRod Mill for Beneficiation

rod mill technical specification of 40tph

Tph Rod Mill 30 to 40 tph comprehensive portable crushing plant beneficiation rod mill weight grinding mill china the ball mill is a key equipment to grind the crushed rod mill intermittent ball mill efficient powder separator dust beneficiation equipment ball mill learn more rod mill technical specification of 40tph More Details Get pricemineral beneficiation plat rod mill China CGM mineral Rod Mill for Beneficiation Steel Mill, Mining,Mineral processing: Capacity: 24250 t/h: Motor Power: kW: Fineness: 01470833 mm: Overview The rod mill for beneficiation is loaded with the grinding media of steel rods「master cylinder mineral beneficiation production Rod mill is one kind of grinding machine and named after the grinding mediasteel rod and generally wet type rod mill is preferable Rod mill can be used as primary opencircuit grinding machine and widely used as primary mill in electrical apartment in artificial sand making, ore beneficiation plant, and chemical plantRod MillMBS Rod millRod Grinding MillCrushing Mill

SGS MINERALS SERVICES – T3 SGS 960 112009

BOND ROD MILL GRINDABILITY TEST The Bond Rod Mill Grindability Test is also performed according to the original Bond procedure It requires 15 kg of minus ½ mesh material that is preferably prepared at the testing facility The Bond Rod Work Index has been widely used for rod mill sizing JKTECH DROPWEIGH TEST ore under a range of impact breakage 2 The use of advanced control access to material rod mill technology, combined with the actual users’ abrasive material to cutters with the appropriate grinding , ball mill is changed the traditional surface contact to line contact, making machine more uniform, higher yields ,and be used in different hardness (Mohs hardness of 55 to 12) of oreRod Mill Haiwang Technology Group Rod mill Feeding size:625mm Output size:05mm Rod mill or grinding rod mill can be widely applied in some fields such as refractory, chemical industry, metallurgy, glass and some other industries that have the higher requirement on the uniformity of the finished productRod millBAILING® Machinery

beneficiation plant what is primary mill

Beneficiation Plant What Is Primary Mill Beneficiation Plant What Is Primary Mill Beneficiation plant illustration of primary mill iron or Beneficiation of primary tin ore copper ore beneficiation plantopper is one of the most famous and useful metals pper ore beneficiation plant is a processing to extract copper from ores copper ore is an ore which can produce copper metal by A rod mill with the peripheral discharge feature is preferred for this application because the ‘”rapidpass” design produces a minimum of the undesirable fines The discharge from the rod mill returns to the Dillon Vibrating Screen by means of a Belt Bucket Elevator, so that a closed circuit grinding arrangement is obtainedChromite Beneficiation Process 911 Metallurgist Ball mill Production capacity:1450t/h Power:451000kw Weight:12156T Ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etcBall millBAILING® Machinery