Portable Crusher Maintenance and Repair Process

Portable Crusher Maintenance and Repair Process The maintenance of the mobile crusher is of concern to many users, because only careful maintenance can effectively extend the service life of the equipment, thereby creating a more considerable economic value for the user 1 Routine maintenance Proper plan and preparation make the whole repair and maintenance ordered and effective, which helps operators save time, cost, and enhance their safety You can make a checklist just like the following chart in which you can list needchecked jaw crusher parts with a different period then making a mark if you are done with themThe Most Practical Jaw Crusher Repair and A Basic Overview of Crusher Maintenance and Repair May 18, 2017 By Tom McIntyre Construction equipment is essential for not only the construction industry itself, but for each industry that’s able to function after the building or structure has been A Basic Overview of Crusher Maintenance and Repair

Crusher Equipment Welding Alloys

4 Crushers Repair and Maintenance u WA 3DCarbTM A proven technology to substantially increase the service life of heavily wearing critical parts • Wear resistant blocks produced by automated flood welding • Reinforced components as a result of the increased volume of wear resistant material and innovative geometry • Even wear resistance Maintenance of Jaw crusher Shut down the jaw crusher regularly and check the machine Check the interior parts wear condition at regular intervals, such as feeder pipe, impeller, circular guard plate, wearresistant block, etc Replace or repair Maintenance and Repair of Jaw Crusher JXSC MineCrusher maintenance and repairs Implementing a preventive and predictive maintenance program is a key factor to extending or maximizing your crusher performance Proper maintenance doesn’t only help extend crusher life, but it allows you to optimize your parts supply, manpower scheduling, and repair Crusher services Outotec

Crusher Service Maintenance Servicing CMS Cepcor

Regardless of the manufacturing brand, application and operator maintenance schedules, it has to be considered that crushers have an arduous life and it is the nature of the beast that crushers will likely suffer from unplanned breakdowns that can be expensive to repair – whether caused by component fatigue failure, lubrication or uncrushable Minor repair: According to the overall operation of the machine, check and repair the corresponding adjustment device, adjust the clearance of the discharge port, and then replace the worn liner; clean the individual parts of the crusher ; The thrust plate should also be repaired and replaced with corresponding transmission componentsRepair and Maintenance of Jaw Crusher China Henan The regular maintenance and repair include adjustment of the gap between the rotor of the impact crusher and the impact lining plate, replacement of wearing parts, regular inspection of the hammer, lining plate, bearing temperature, etc Replace badly wearing parts in time Regularly inspect temperature of the rotor, motor and bearing, etc4 Types of Stone Crushers' Maintenance and Efficient

Briefly describe the maintenance and repair of the

The use of coarse crusher factories and mines should formulate a regular maintenance system according to the nature of the materials and production requirements Regular maintenance is generally divided into minor repairs, medium repairs and overhauls The maintenance content and cycle are as follows 1 The content and period of minor repairsMaintenance And Repair Of Jaw Crusher Machine Secondly, the jaw crusher jaw repair In order to ensure the normal operation of jaw crusher, in addition to operate correctly, planned repair is essential, which includes daily maintenance and inspection, maintenance, repair and overhaul 1, Except for repair work, overhaul also includes the replacement of turning eccentric shaft and theCrusher Maintenance And Repair trinitytrade crusher equipment and has designed a specific range of cored wires with wear characteristics to optimise the crushers’ performance, reducing maintenance costs Hardfacing by arc welding is a surfacing operation using a cored wire to extend the service life of specific components This is carried out preemptively on newCrusher Equipment Welding Alloys

Industrial Crusher maintenance and rebuilds Prime

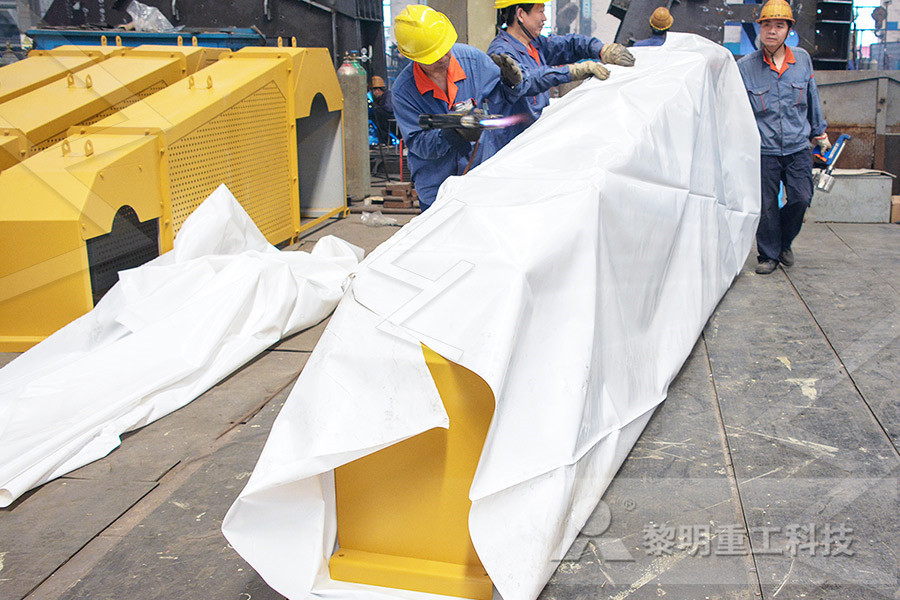

Industrial Crusher maintenance and rebuilds Industrial Crushers rebuilds by Prime Machine Repair of large gyratory cone crusher head by welding and machining machining of cone crusher wear mantle Jaw crusher rebuild Machining eccentric shaft, babbitting and machining of main bearings and jaw bearing, repairs to jaw wear plate fits The maintenance and repair of the crusher equipment is briefly described from three important aspects 1, bearing maintenance The bearing part of the crusher is the most likely to be broken In use, the wear is relatively large, so it needs frequent maintenance It is often necessary to increase the service life of the bearingCrusher equipment maintenance Hongsheng Repair And Maintenance Of Jaw Crushers maintenance manual jaw crusher pdf – Crusher South Africa Download: Repair manual for extec c12 jaw crusher at Marks extec x44 cone crusher pdf tw – i Repair And Maintenace For A Cone Crusher Crusher

4 Types of Stone Crushers' Maintenance and Efficient

The most practical jaw crusher repair and maintenance manual Other ways to protect your jaw crusher parts Replaced jaw plate with more than 12% manganese (ZGMn13) can greatly increase the service life of the jaw plate The crusher has a blade and this makes the work to be easy and quick, it does not make noise, little energy is needed to use the machine Maintenance of crusher machine You need to put the plastic crusher where there is ventilation this is highly needed Always check the grease level and add to it always, this allows lubricity of bearingUses, Working Principles And Maintenance Of Plastic Crushing Plant and Equipment have fully qualified crusher fitters and repairers each with many years’ experience working on a wide variety of manufacturer’s equipment Our workshop is fitted with several overhead cranes, machining equipment and everything required to perform anything from minor repairs to full crusher rebuilds and overhaulsRepairs Maintenance Fully Qualified Crusher Fitters

hammer crusher maintenance and repair procedures

Hammer Mill Crusher Grinder 911 Metallurgist Mar 12, 2018 The hammer mill is the best known and by far the most widely used view of which is shown here on the left, the process is, in one important respect, to a minimum and maintenance and repair part costs are extremely low,We also offer crusher maintenance and repair services to extend or maximize the performance of your crusher, and our field service technicians and technical support are always there for you Crusher spare parts Reliable crusher spare parts enable stable production without unexpected downtimeCrusher wear parts OutotecRegardless of the manufacturing brand, application and operator maintenance schedules, it has to be considered that crushers have an arduous life and it is the nature of the beast that crushers will likely suffer from unplanned breakdowns that can be expensive to repair – whether caused by component fatigue failure, lubrication or uncrushable Crusher Service Maintenance Servicing CMS Cepcor

Crusher Maintenance Services Crusher Maintenance

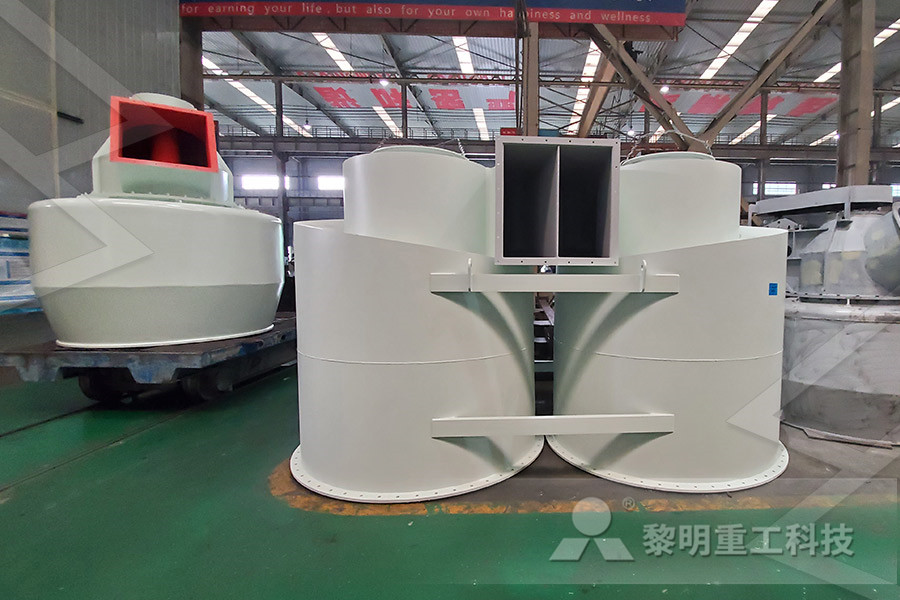

There are numerous types of crushers, including jaw, gyratory, cone crusher and impact crusher But crushers are only ever as good as the parts and the upkeep that goes into them, so it’s vital to have quality crusher maintenance services on hand to ensure longevity and optimal performanceLearn more about the repair and maintenance of the jaw crusher 2020/06/02 Maintenance of jaw crusher In order to ensure the normal operation and proper operation of the jaw crusher, scheduled maintenance must be carried out, including routine maintenance inspection, minor repair, medium repair and major repair Get Pricecrusher routine maintenance inspectionCrushing Plant and Equipment have fully qualified crusher fitters and repairers each with many years’ experience working on a wide variety of manufacturer’s equipment Our workshop is fitted with several overhead cranes, machining equipment and everything required to perform anything from minor repairs to full crusher rebuilds and overhaulsRepairs Maintenance Fully Qualified Crusher Fitters

Uses, Working Principles And Maintenance Of Plastic

The crusher has a blade and this makes the work to be easy and quick, it does not make noise, little energy is needed to use the machine Maintenance of crusher machine You need to put the plastic crusher where there is ventilation this is highly needed Always check the grease level and add to it always, this allows lubricity of bearingThe Most Practical Jaw Crusher Repair and Maintenance 11/3/2021 Just like other stone crusher machines, jaw crusher also needs a regular repair and mainjaw crusher maintenance and repair Repair of jaw crusher There is inevitable come with fault, in addition to the correct operation of the jaw crusher,scheduled maintenance and repair must be carried out Minor repairs including conventional checking drive system, lubricating system, andadjust jaw plates, replace wear partsJaw Crusher Repair And Maintenance Of Aircraft

OnSite Crusher Service OnSite Crusher Repair

Home » Crusher Service » Crusher OnSite Service Crusher OnSite Service Parts Installation, Maintenance and Repairs Certified CMS Cepcor® crusher service technicians and crusher engineers can be contracted to complete onsite parts installation, crusher service, inspections and repairs on a wide range of crushing, screening and asphalt plant worldwideThere are roughly three types of jaw crusher planned maintenance: minor repair, medium repair, and overhaul Minor repairs and medium repairs are the main repair methods Through minor repairs and intermediate repairs, the equipment is maintained to perform well during the two overhauls and to determine the work of the overhaulJaw Crusher Maintenance Management Crusher rollers, crusher hammers, asphalt mixer blade, agricultural tools, shovel bucket teeth and lips, bulldozer blades, cane knives and shredders, bed knives in the wood pulp industry General repair and nickel base 50 HRC SK 900NiG Flux cored wires containing about 45 % Tungsten carbides particles, incorporated in a matrix alloyed with CrNiBREPAIR AND MAINTENANCE WELD OVERLAY SOLUTIONS