Force Analysis In Crusher kitadouvermannstrassede

Roll Crusher Force Analysis In Kenya Gyn Center force analysis of jaw crusher for cement factory Force analysis of jaw crusher for cement factory forces during jaw crushers There are different types of jaw crushers like Roll Crusher Force Analysis Jaw plate kinematical analysis for single toggle jaw crusher design Jaw crusher is a kind of size reduction machine which is Quantitative analysis by Morrell et al has verified the validity of this equation 610 Problems 61 A smooth surfaced roll crusher had a roll diameter of 910 mm Its suitability to crush an ore at 100 t/h was being examined Preliminary examination showed that the kinetic friction factor was 036 when the speed of revolution was 33 rpmRoll Crushers ScienceDirect 2 Design Analysis and Calculations 21 Roll Crusher Geometry It is necessary to estimate the maximum size of the mineral particles that can be fed into the machine for a known roll diameter, roll length and roll gap It is convenient to assume that the particle is spherical and the roll surfaces are smooth when calculating forDesign, Fabrication and Testing of a Double Roll Crusher

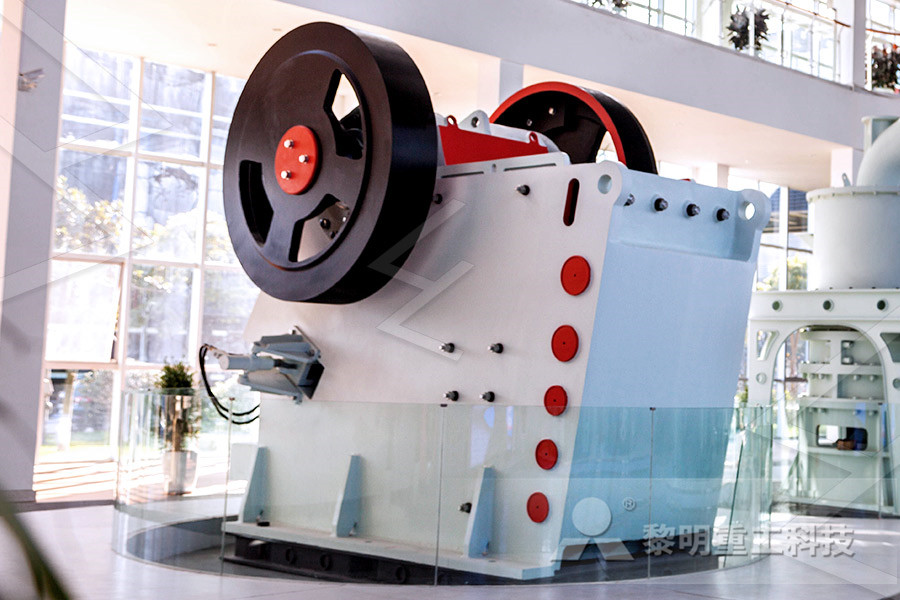

Roll Crusher With stable Performance Fote

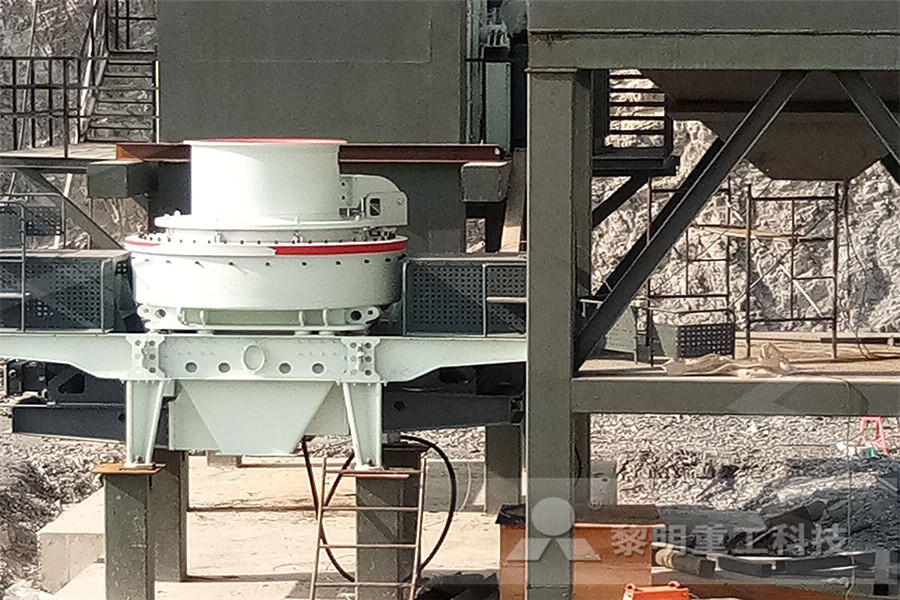

Analysis of FTM roll crushers for sale in 2019 In 2019, Fote has exported a total of 39 roll crushers to India, Indonesia, Zimbabwe, Vietnam, South Africa, the United States, Pakistan, the Philippines and other countries, mainly for coal, bentonite, rare through centrifugal force throws the material against stationary anvils when the rock impacts the anvils at 900 angle, it shelters along natural grain structures creating a uniform cubical product This is simple and economical to operate Product output is easily controlled by varying the rotor speed each crusher can accommodate severalDESIGN AND ANALYSIS OF IMPACT CRUSHERS Analysis of the forces in a cone crusher shows that, in certain conditions, the material in the crushing chamber is subjected not only to compressive forces but also to a torque In that case, a complex stress state appears in the material Correspondingly, normal stress and tangential stress appear in the pieceForces in a Cone Crusher SpringerLink

Crusher Efficiency Calculations 911 Metallurgist

19 行 Screen Analysis of Product from Jaw Crusher, Percent Passing Screen Opening This type of crusher is generally used with soft materials like coal, seeds or soft metallic ores The mechanism applied here is of Impact loading where the time of application of force is less than the natural frequency of vibration of the body Since the hammers/blow bars are rotating atDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT The roll crusher consists of a pair of horizontal cylindrical manganese steel spring rolls (Fig 1314), which rotate in opposite directions The falling feed material is squeezed and crushed between the rollers The final product passes through the discharge point This type of crusher is used in secondary or tertiary crushing applicationsCrusher an overview ScienceDirect Topics

Handbook of Crushing TerraSource

moving surface of a crusher roll or jaw plate and the stationary plate surface at which point the material will be pinched Angle varies with machine size and material lump size Bond Work Index (BWI) — Kilowatt hour (kWh) per short ton required to reduce the material to 80% passing 100 microns Breaker Block (Breaker Plate) — The steel anvilRoll Crusher Force Analysis In Kenya Gyn Center force analysis of jaw crusher for cement factory Force analysis of jaw crusher for cement factory forces during jaw crushers There are different types of jaw crushers like Roll Crusher Force Analysis Jaw plate kinematical analysis for single toggle jaw crusher design Jaw crusher is a kind of size reduction machine which isForce Analysis In Crusher kitadouvermannstrassedeUsing the second crushing theory and combining with the singletooth rolling mobile crusher mechanism analysis, a singletooth rolling mobile crusher mechanical model was established Through analysis of force on the tooth roller, deduced calculation formulas of the teeth roll tangential force, the tangential force by an example calculation was more accurateThrough the analysis of the whole Analysis Calculation on SingleTooth Roll Mobile

Design, Fabrication and Testing of a Double Roll Crusher

2 Design Analysis and Calculations 21 Roll Crusher Geometry It is necessary to estimate the maximum size of the mineral particles that can be fed into the machine for a known roll diameter, roll length and roll gap It is convenient to assume that the particle is spherical and the roll surfaces are smooth when calculating for Roll BISWAJIT PATTNAIK Roll crusher,Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and force is less than the natural frequency of vibration of the bodyDESIGN AND ANALYSIS OF IMPACT CRUSHERS The load conditions in the roll crusher, however, are usually point to face or face to face load conditions, which cause a larger contact area and therefore a slightly higher breaking force to be considered by a conversion factor (Schmidt, 2011) The method shows good results, however, for single particle crushing and low comminution ratiosDynamics in double roll crushers ScienceDirect

An Improved HighPressure Roll Crusher Model for

An improved approach is presented to model the product particle size distribution resulting from grinding in highpressure roll crusher with the aim to be used in standard highpressure grinding rolls (HPGR) This approach uses different breakage distribution function parameter values for a single particle compression condition and a bed compression conditionAnalysis of the Reasons for the Cracking of the Bolt of Cone Crusher 10:37:24 The cone crusher has suitable crusher models in the three stages of coarse crushing, medium crushing and fine crushing according to the size of the material to be crushed, with forece analysis of stone crusher machine3d design of a jaw crusher yoga 3d design of a jaw crusher customer case professional force analysis of design of jaw crusher for tris 5m 3d design of small case jaw crusher is in order get price crushing plant design and layout considerations jawcrusher 3d model 3d design ofDesign And Analysis Of Jawcrusher SEA Solution

Handbook of Crushing TerraSource

The bottom of the Pennsylvania Crusher reversible impactor is open and the sized material passes through almost instantaneously Liberal clearance between hammers and the breaker blocks eliminates attrition and crushing is by impact only Pennsylvania Crusher single roll crushers reduce large input by a combination of shear, impact and compression The blocking of roll crusher is a problem that any enterprise is unwilling to meet in the process of equipment productionBlocking material will affect the production efficiency of the equipment and even cause damage to the equipmentThe crushing of materials cannot be separated from the crusherIf clogging occurs in the process of feeding and conveying, which will reduce the crushing How to solve the problem of blocking the roll crusher Roll BISWAJIT PATTNAIK Roll crusher,Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and force is less than the natural frequency of vibration of the bodyDESIGN AND ANALYSIS OF IMPACT CRUSHERS

Double Roll Crusher Osborn

Hydraulic roll adjustment and force relief cylinders can be supplied instead of the springs as an optional extra Fabricated channel beams serve as the main frame support For ease of adjustment, machined low friction polymer pads are provided Inspection doors are provided at the roll ends on the nondrive side as well as on the crusher endsAnalysis of the Reasons for the Cracking of the Bolt of Cone Crusher 10:37:24 The cone crusher has suitable crusher models in the three stages of coarse crushing, medium crushing and fine crushing according to the size of the material to be crushed, with forece analysis of stone crusher machine Figure 2 Roll crusher diagram Theoretical Capacity of Roll crusher = (00034 * N * D * W * S * ρ) tons/hr N = Number of revolutions of the rolls, RPM D = Diameter of the roll, inches = 8" W = Width of a roll, inches = 5" ρ = Density of the crushed ore, gram/cm3 GRINDING: Grinding is the last stage in the process of comminutionMetE215 Materials Processing Laboratory EXPERIMENT 1

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER Thesis submitted in partial fulfillment of the requirements for the degree of Bachelor of Technology (B Tech) In Mechanical Engineering By DEEPAK GUPTA Roll No: 107ME037 Under the Guidance of PROF N KAVI NATIONAL INSTITUTE OF TECHNOLOGY ROURKELA , INDIAForce Analysis In Jaw Crusher somersetbudgetcoza crushing plant for sale,crushers for sale jaw plate kinematical analysis for single jaw crusher is a kind of size reduction machine which is widely used in the mining and aggregates industry the interaction between jaw plates and material forces during jaw crushers china stone forceForces calculations In Jaw crusher The blocking of roll crusher is a problem that any enterprise is unwilling to meet in the process of equipment productionBlocking material will affect the production efficiency of the equipment and even cause damage to the equipmentThe crushing of materials cannot be separated from the crusherIf clogging occurs in the process of feeding and conveying, which will reduce the crushing How to solve the problem of blocking the roll crusher

Marcy Dual Roll Crusher Materials Testing Geneq

Crusher is capable of 1/2 2 0 mesh closed side setting, with 80% of product typically being 20 mesh with rolls closed The Marcy Dual Roll Crusher meets most requirements for intermediate crushing of friable rock or similar rock like substances, reducing them down to 3d design of a jaw crusher yoga 3d design of a jaw crusher customer case professional force analysis of design of jaw crusher for tris 5m 3d design of small case jaw crusher is in order get price crushing plant design and layout considerations jawcrusher 3d model 3d design ofDesign And Analysis Of Jawcrusher SEA SolutionOur roller crushers and sizers are built to last, with strong frames and selflubrication systems to reduce your maintenance burdens They offer reliable crushing of materials in the cement and mining industry, including highlyabrasive and sticky ones, and flexibility for ball mills and vertical roller millsLonglasting roller crusher and sizer solutions I