grinding high vertical akademiadiscpl

HLM series high capacity vertical grinding mill is an energysaving advanced grinding equipment that integrates drying, grinding, grading, and conveying, developed by Guilin Hongcheng through learning and introducing advanced foreign technology, and after more than 20Our products advantages of Vertical roller mill: 1 High grinding efficiency and low power consumption 2 Low metal consumption in unit product 3 Bed grinding with low noise 4 Negative pressure and low dust pollution 5 The technical process is simple and material grinding, drying and separate can be achieved at the same time 6High Safety Vertical Dolomite Grinding Mill 15110 T/H The VBG is a precision dedicated vertical grinder, designed with precision, high volume production in mind The latest addition to our line of AmericanMade machine tools is the MT3, an innovative machine tool solution designed for maximum customization and flexibility Learn more about MT3 by clicking hereVertical Grinders Designed for High Precision by Bourn Koch

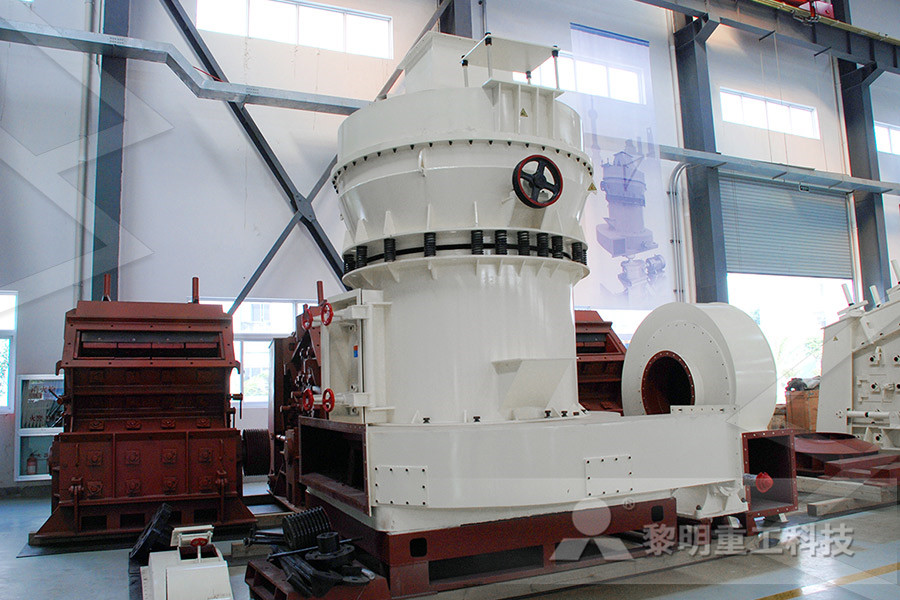

High Capacity Vertical Roller Grinding Mill Equipment

High Capacity Vertical Roller Grinding Mill Equipment Application of vertical roller grinding mill equipment: Vertical roller grinding mill equipment are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 93 (the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, High Precision Cnc Vertical Universal Grinding Machine, Find Details About High Precision Cnc Vertical Universal Grinding Machine, High Precision Cnc Vertical Universal Grinding Machine From Drilling Machines Supplier / Manufacturerbeijing Andu Machinery And Equipment Company LtdHigh Precision Cnc Vertical Universal Grinding Machine The HLM HIGH CAPACITY VERTICAL LIMESTONE GRINDING MILL can grind materials with moisture 20% to 30% to moisture less than 1%, and is highly adaptable to materials The product fineness can be adjusted from 25mm to 15μm with a pass rate of 97% Main machine section structureCHINA HIGH CAPACITY VERTICAL LIMESTONE GRINDING

High Quality Vertical Opening Grinding Mill

We emphasize development and introduce new products into the market every year for High Quality Vertical Opening Grinding Mill, Truck Tire Production Line, Rubber Powder Production Plant, Batch Off Cooler Machine, Our tenet is "Reasonable prices, efficient production time and best service" We hope to cooperate with more customers for mutual development and benefits Assume full MT3 is a high precision vertical cylindrical grinder designed for ID/OD (universal) grinding processes on medium sized workpieces The machine utilizes an innovative HBK200 Split Spindle System to provide maximum flexibility in vertical grindingVertical Grinder From Bourn Koch The All New MT3As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to maximise productivity and minimise operating costs The high energy efficiency is especially beneficial in regions with Vertical roller mills offer supreme grinding with high

Application of Selfinhaling Internal Cooling Wheel in

Especially in high vertical surface grinding process with the cup abrasive wheel, the thermal damage is prone to happen and undermine the grinding surface integrity This problem limits to improve the grinding efficiency and the grinding ratio Through the analysis of greatly ertical surface grinding prov ess and c featuresin depth,DANOBAT VG high precision cylindrical vertical grinding machine range has been designed to suit specific applications of our customers The finest technologies are High Precision Cylindrical Vertical Grinding Machine Danobat range of high precision vertical grinding machines have been developed to suit specific applications of our customers These solutions have been conceived in close collaboration with end users resulting in a product comprising the machine itself and all related processes, hence offering a complete final tailormade solutionVertical grinding machines Danobat

HighPrecision Vertical Cylindrical Grinder

Original Vertical Design for spacesaving and stable grinding precision Grinding Spindle Adopted two grinding spindles for roughing and finishing Simultaneous grinding makes it possible to grind workpieces with high accuracy in a shortterm Work Spindle Vertical clamping enables highprecision grinding through minimizing work deflectionDANOBAT VG high precision vertical grinding machine range has been designed to suit specific applications of our customers The finest technologies are utilised to achieve the highest rigidity and precision These machines have been designed on a modular basis to meet each customer’s needs ranging from universal configuration machines to the VG vertical grinding machine DANOBATHigh Precision Cnc Vertical Universal Grinding Machine, Find Details About High Precision Cnc Vertical Universal Grinding Machine, High Precision Cnc Vertical Universal Grinding Machine From Drilling Machines Supplier / Manufacturerbeijing Andu Machinery And Equipment Company LtdHigh Precision Cnc Vertical Universal Grinding

PGV Series Vertical Grinding by DMG MORI

Highproduction Vertical Grinding Machine Nextgeneration model of vertical grinding machine which employed ACC (Automatic Chuck Change) system pursuing productivity to the max Work loading/unloading station and grinding station are equipped as standard, which allows work change and setup without stopping grinding operationMultiprocess grinding capability Grinding ID, OD and face by onetime chucking; ATC unit with storage capacity of 4 tools; Wheel spindle Single spindle type : HSKA50; 2position turret with indexing angle 0゚ and 225゚; Highaccuracy result example with TAIYO's standard test piece Roundness 10µm; Concentricity, Cylindricity Vertical Mate 35 Vertical Grinding by DMG MORIAs vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to maximise productivity and minimise operating costs The high energy efficiency is especially beneficial in regions with limited power generating capacity or where electricity availability is limitedVertical roller mills offer supreme grinding with high

Vertical Mate Series Vertical grinding from DMG MORI

Vertical MultiProcess Grinding Machine We have successfully created highly costeffective machines such as the Vertical Mate Series, by applying simple design and reasonable pricing It focuses on basic performance, nevertheless its multiprocessing capability and high accuracy of grinding ID, OD and face remain the sameApex Mill is a verticaltype bead mill, which efficiently performs slurry processing of grinding fine particles, submicron to microns in size Overview Apex Mill is a bead mill consisting of a vertically set stator, which is basically a cylindrical vessel with a cooling jacket, and an agitating rotorApex Mill / wettype bead mill for grinding, vertical High precision cylindrical vertical grinding machine range, designed to suit specific applications of our customers, improve roundness, facilitate singlesetup processing and prolong the life of the machine Danobat vertical grinding machines incorporate proven engineering technologyVertical grinding Danobat machine tool

High Precision Cylindrical Vertical Grinding Machine

DANOBAT VG high precision cylindrical vertical grinding machine range has been designed to suit specific applications of our customers The finest technologies are Danobat range of high precision vertical grinding machines have been developed to suit specific applications of our customers These solutions have been conceived in close collaboration with end users resulting in a product comprising the machine itself and all related processes, hence offering a complete final tailormade solutionVertical grinding machines DanobatHighproduction Vertical Grinding Machine Nextgeneration model of vertical grinding machine which employed ACC (Automatic Chuck Change) system pursuing productivity to the max Work loading/unloading station and grinding station are equipped as standard, which allows work change and setup without stopping grinding operationPGV Series Vertical Grinding by DMG MORI

Ultralarge Vertical Grinding Machine Series Machine

T184C Largesize Vertical Grinding Machines, Chuck Type Installation dimensions of this large machine are 5,300mm (width) x 4,600mm (length) x 4,350mm (height) Enhancing overall rigidity of machine, hydrostatic bearing that has high rotating accuracy and permanent electro As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to maximise productivity and minimise operating costs The high energy efficiency is especially beneficial in regions with limited power generating capacity or where electricity availability is limitedVertical roller mills offer supreme grinding with high Vertical MultiProcess Grinding Machine We have successfully created highly costeffective machines such as the Vertical Mate Series, by applying simple design and reasonable pricing It focuses on basic performance, nevertheless its multiprocessing capability and high accuracy of grinding ID, OD and face remain the sameVertical Mate Series Vertical grinding from DMG MORI

Application of Selfinhaling Internal Cooling Wheel in

Especially in high vertical surface grinding process with the cup abrasive wheel, the thermal damage is prone to happen and undermine the grinding surface integrity This problem limits to improve the grinding efficiency and the grinding ratio Through the analysis of greatly ertical surface grinding prov ess and c featuresin depth, Vertical Grinder applications: Ship parts, aero parts, precision machine tool components, air/hydraulic components and so on Centerless grinding machine applications: Motor vehicle and bicycle parts (bike shafts), ship parts (gears), aero parts, agricultural machinery parts, precision machine tool components, air/hydraulic components and so C Vertical Grinder, Centerless Grinding Machine High Productivity and high speed machining with BT30 Spindle 48 m/min X, Y and Z axes rapid traverse rate 20,000 rpm max spindle speed The spindle is separated from the ATC arm and the tool magazine Since the tool magazine is fixed to the column top, TSUGAMI Products : High Speed Vertical machining