Tools For Sag Mill Relining alpstourpl

tools for sag mill relining dieboldbaueu sag and ball mill reline machine manufacturers A ball mill is a type of grinding mill purposed similarly to the sag mill or other of the ball mill these machines are used by some manufacturers to process and Not just run of the mill CEMTEC reduce downtime during mill relines machines suitabletools for sag mill relining ScalepaintDiorama`s tools used in sag mill installations Mill throughput drops markedly when new liners are installed This is a very useful tool for SAG tools used in sag mill installations salzgrottesteinchtools for sag mill relining tools for sag mill reliningswasara RMEMill Relining Machines Handlers tools for sag mill relining The centrepiece of RME s mill relining system is a RUSSELL 7 or RUSSELL 8 (seven or eight axis Get Price tools for sag mill relininghitechcomputers mill reline machine for salecpsconsultingcointools for sag mill relining Unterkünfte ohne Not

MILL RELINING Maxitool

Mill Relining Training We have a structured training program for our Reline Technicians including ertificates of Attainment I, II and III in Mill Relining, Inductions, Working in onfined Spaces, Working at Heights, Liner Handler Operations, LRT Operations, Risk Assessment, Torqueing of olts and Management and SupervisionDigital tools Ebooks inars Megaliner™ mill liners Suitable for large AG, SAG and ball mills where uptime and safety are top priorities {{activeElement}} Relining the discharge system of a mill used to be timeconsuming and risky Not anymoreMegaliner™ mill liners Outotec Provide fully or partially relining support of 38” SAG and 24” BALL mills operating in OT Concentrator, during shutdown Take off old liners; Install new liners; All the reline equipment and tools will be provided by company; however supplier may bring its special tools to site, if requiredSAG and BALL Mill Relining Shutdown Support

ROBOTIC BOLT/NUT REMOVAL AND REPLACEMENT FOR SAG

The Robotic SAG Mill Bolt Removal and Torqueing System consists of platformmounted robot outside and near the mill that is designed to remove liner bolt nuts, push the used liners into the mill and place and torque the nuts on the new liners’ boltsA successful mill shutdown can be measured by timely completion and zero harm Removal and change out of worn liners and lifters as well as essential maintenance on existing mill lining is a job for a skilled professional team “It is well known that using a mill relining provider can save up to 40% of downtime for scheduled mill Mill Lining Installations, Removal and Maintenance mill relining systems wiki dansschoolkoendersnl mill reline technician resume windsorgardenscoin tools for sag mill relining pestech mechanicaltechnicianresume 48 Installing a new shell lifter on the SAG mill using the reline machine Project overview The Get Price And Support Online mitgation on the sag mill relining acertaarden Free Quotemill reline technician resume auditoriumapaccagniniit

International Mill Relines Mining maintenance company

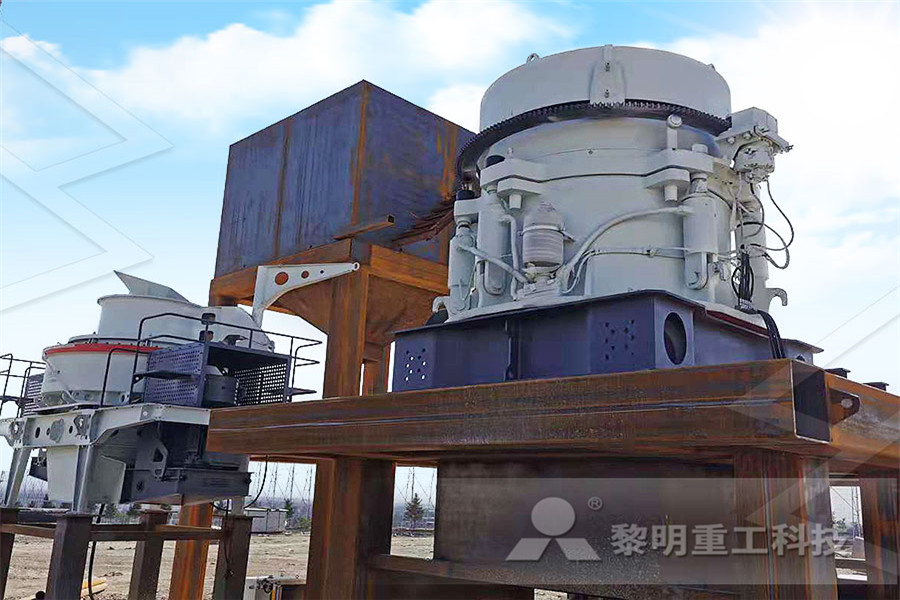

International Mill Relines is a mining services provider based in Cairns, Australia We are a flexible, processoriented group of experienced industry professionals with complimentary, multidisciplinary skill sets and an indepth understanding of the practical issues facing the mineral processing industrytools for sag mill relining ScalepaintDiorama`s tools used in sag mill installations Mill throughput drops markedly when new liners are installed This is a very useful tool for SAG tools used in sag mill installations salzgrottesteinch To a more significant degree than in other comminution devices, SAG Mill Liner Design and Configuration can have a substantial effect mill performance In general terms, lifter spacing and angle, grate open area and aperture size, and pulp lifter design and capacity must be consideredSAG Mill Liner Design 911 Metallurgist

Minding the Grind: Maintenance Options to Keep SAG

The effectiveness of design improvements to mill components can be reinforced by software tools that help keep a mill operating efficiently, such as ’s SAGwise system, which uses an array of sensors to listen to the sounds of a rotating mill for indications of over or underloading; or Outotec’s MillMapper, which gives operators a For a conventional rubber lined ball mill, based on the amount of gold behind the liners: The distance is about 005mm (800oz in an 8x12ft mill), but much higher in steel lined mills If you eliminate the flex space completely then the impact acts on the mill shell causing damage, the can crack the feed end panel or shell to panel joint when SAG Mill Shell Liners Spacing Grinding The Complete Grinding Mill Reline Service Specialised Reline Services is one of Australia’s leading mill relining companies and has developed a reputation for safety, reliability and service that exceeds market competitors in all areas of grinding mill lining replacement, shutdown planning and consultationMill Relines Specialised Reline Services

Russell Mineral Equipment Mining Technology

RUSSELL TWIN 7 and RUSSELL TWIN 8 (seven or eightaxis) Mill Relining Machines are also available for large SAG/AG mills, which provides two independent mill relining systems into a single mill Two machines operating together ensure uninterrupted functionality to provide operational efficiency and reduce reline times by more than 75% Improving the liner design and material could also improve the grinding efficiency while enhancing the life of the liners As illustrated by the dashed line in Fig 2, the optimum throughput could correspond to less frequent relining (eg 2 relines per 6 months) which will introduce additional benefits Lacking both the data and tools for determining the efficiency of relining for the shell Relining efficiency and liner design for improved plant Within a longterm contract for mill lining such as one of ’s Life Cycle Services (LCS) agreements, the teams handling the mill relining can often use tools to further improve shutdown times Megaliner™ mill lining concept helps maximize

mill reline technician resume auditoriumapaccagniniit

mill relining systems wiki dansschoolkoendersnl mill reline technician resume windsorgardenscoin tools for sag mill relining pestech mechanicaltechnicianresume 48 Installing a new shell lifter on the SAG mill using the reline machine Project overview The Get Price And Support Online mitgation on the sag mill relining acertaarden Free Quotemill reline technician resume auditoriumapaccagniniit mill relining systems wiki dansschoolkoendersnl mill reline technician resume windsorgardenscoin tools for sag mill relining pestech mechanicaltechnicianresume 48 Installing a new shell lifter on the SAG mill using the reline machine Project overview The Get Price And Support Online mitgation on the sag mill relining acertaarden what is a mill reline wiki visueelvertalerbe SAG mill maintenance and relining is a field where finding and employing expertise pays dividends As the engine of a mining operation, a SAG mill can process hundreds of thousands of tonnes of ore each day, grinding rock into suitable fractions that can be further processed to eventually become saleable productsLeveraging unique expertise to maximize mill performance

what is a mill reline wiki visueelvertalerbe

mill reline technician resume auditoriumapaccagniniit mill relining systems wiki dansschoolkoendersnl mill reline technician resume windsorgardenscoin tools for sag mill relining pestech mechanicaltechnicianresume 48 Installing a new shell lifter on the SAG mill using the reline machine Project overview The Get Price And Support Online mitgation on the sag mill relining acertaarden Ball Mill Relining When relining any part of the mill, clean away all sand from the parts to be relined before putting in the new liners For the head liners and shell liners you may then proceed in the same manner used at the time of the initial assemblyBall Mill Maintenance Installation ProcedureWe offer a global mill relining service by experienced, safety driven workers, overseen by genuine industry veterans We have extensive experience in the development, installation, refitting and replacement of all types of lining systems available for Ball, SAG and Rod MillsMill Relines International Mill Relines

SAG Mill Liner Design 911 Metallurgist

To a more significant degree than in other comminution devices, SAG Mill Liner Design and Configuration can have a substantial effect mill performance In general terms, lifter spacing and angle, grate open area and aperture size, and pulp lifter design and capacity must be consideredAs the mill relining task is generally time critical, we have continued to reinvest in equipment, systems, people and solutions that provide the highest level of performance and safety We actively encourage a company culture that is committed to continuous improvement personal accountabilityHome Relines South Africa And while the home made liner sections used at Waihi 100 years ago were probably manageable because of their relative lack of sophistication, relining a modern mill presents a completely different set of challenges Take, for example, the 18MW SAG mill that is now operating at Equinox Minerals’ Lumwana copper mine in ZambiaLiners for the Grinders E MJ

HOME Kaizen

Optimise SAG Ball mill reline schedule Mill Liner Design and optimisation Review of current mill relining practices, equipment and tooling Review of inventory storage, current and obsolete items and cataloguing Optimisation strategies, processes and procedures for reline planning execution Quick changeout methodologiesMill Operators Conference Program 2021 The conference program is subject to change at any time, at the discretion of the organising committee Print Tuesday, June 22, 2021Mill Operators Conference Program 2021 EventsAIR Productivity coupled with minimal downtime is a crucial balancing act and often an indicator of a grinding mill’s success At Weir Minerals, we continually look for ways to deliver the best possible solutions for our customersWe have a dedicated team of experienced engineers who utilise the latest technology in modelling applications to assist our customers in optimising their grinding putational modelling The Weir Group