ROLLER PRESSES Finish grinding by Roller Press

Finish grinding by Roller Press Roller Press technology has long since proven its ability to grind raw materials and slag in a costeffective way However, the technology is increasingly making its mark with cement producers for the finish grinding of cement n by Dr Stefan Seemann, Kai Weider, Carsten Eckert and Daniel Uttelbach, KHD Humboldt Wedag,High Pressure Grinding KHD Humboldt Wedag Roller Presses With our Roller Presses, the grinding pressure is transferred from the hydraulic system via the movable roll to the material bed and absorbed in a stable, closed machine frame A key feature is the mounting of High Pressure Grinding Roller Presses KHDGrinding Rolls LYHMC Roller Presses offer rollers with appropriate wear protection for almost all applications in the cement and minerals industryperiod; The twopart roller consisting of shaft and tire allows for economical surface replacementcomma; single part rollers China Roller Press Grinding RollsRoller Press Roller

Roller press: Efficient grinding solutions

Focusing on main technology today, it is globally known that roller presses are the best solution for grinding circuits with lowest electrical energy in cement production process Comflex grinding system from KHD consumes less energy compared to other similar process circuits and is a proven fact for raw material, slag grinding and composite cement grindingRoller press technology for grinding and milling Decrease your maintenance downtime and improve and promote health and safety, with established Roller press HPGR technology solutions High Pressure Grinding( Roller Presses ) With our Roller Presses, the grinding pressure is transferred from the hydraulic system via the movable roll to the material bed and absorbed in a stable, closed machine frame A key feature is the mounting of the rollers in oillubricated cylindrical roller bearings The oil is both, lubricant and cooling agentCement Roller Press High Pressure Grinding Roll

The Hydraulic Roller Press offers costsaving grinding

The Hydraulic Roller Press has the capability to grind raw material, cement clinker or slag and is suitable even for dry feed materials and there is no need to add water to the roller press while processing Improve production while reducing energy consumption The flexible Hydraulic Roller Press Roller Presses for Briquetting, Compaction and Grinding Köppern roller presses are centered around two counterrotating rollers, supported in the frame by spherical, selfaligning roller bearingsKöppern Roller Presses Maschinenfabrik KöppernHigh Pressure Grinding( Roller Presses ) With our Roller Presses, the grinding pressure is transferred from the hydraulic system via the movable roll to the material bed and absorbed in a stable, closed machine frame A key feature is the mounting of the rollers in oillubricated cylindrical roller bearingsChina High Pressure Grinding Roller (HPGR) China

Roller presses Applications Flender

Highpressure rolling mills and rotary kilns are particularly demanding applications that call for maximum performance and reliability from the drive systems The grinding process must be guaranteed energyefficient and reliable at the same time Our planetary gear units have been used as drives in roller presses and rolling mills for decadesRoller press machines for pregrinding, semifinish finish grinding For extreme efficiency and high equipment availability, look no further than roller press technology and products from The roller press is a uniquely designed comminution tool, in that feed ore is exposed to extremely high pressure for a short amount of time Roller press HPGR technology solutions Mills of various types are used in cement works, from grinding the raw material through to crushing the clinker into fine powder Alongside vertical and ball mills, roller presses have proved suitable for a wide range of applications When powered by hydraulic direct drives cement manufacturing machinery can achieve higher productivity and uptime Roller presses Bosch Rexroth AG

Hpgr Cement Roller Press High Pressure Grinding

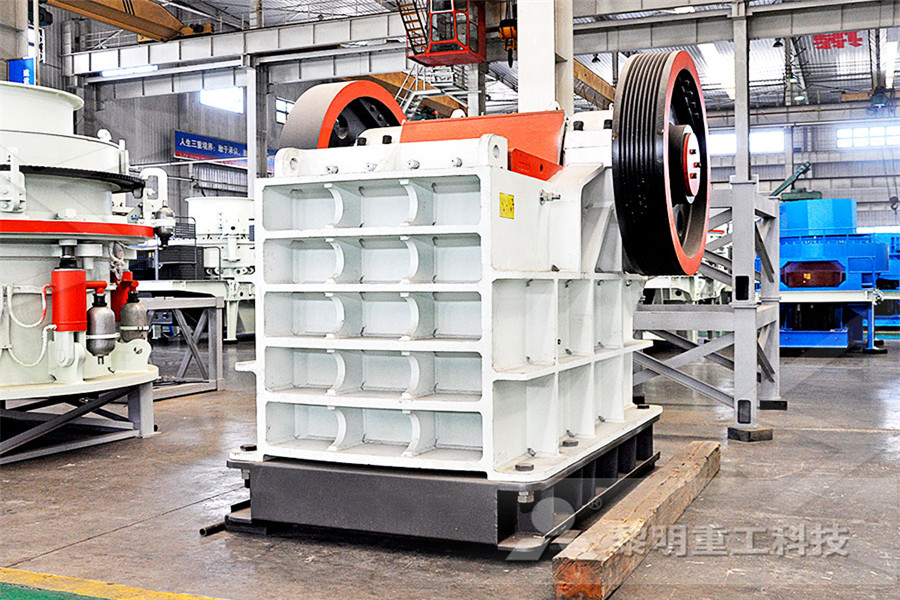

With our Roller Presses, the grinding pressure is transferred from the hydraulic system via the movable roll to the material bed and absorbed in a stable, closed machine frame A key feature is the mounting of the rollers in oillubricated cylindrical roller bearings The oil is both, lubricant and cooling agentThe cement roller press has a high energy utilization rate and remarkable energysaving effect in the material grinding process In cement plant, cement roller press is a kind of important cement equipment used for clinker grinding It is usually combined with a cement ball mill to form a highefficiency cement grinding system because the practice shows that the grinding process with small Cement Roller Press Roller Press In Cement Plant The roller press is often used where energyefficient grinding of large product quantities is required The two rollers, rotating in opposite directions, exert very high pressure on the material, effectively crushing and weakening the particles (microscopic cracks), so that the subsequent fine grinding is easierRoller press Christian Pfeiffer

SAHUTCONREUR Roller Press

The roller press is composed of two rollers : One is fixed in the roller press frame whereas the other one can move perpendicularly to its axis varying the space between them The size of the Roller Press is characterised by the roll diameter (from 400 to 1600 mm HFCG series roller press is proud of being the world NO1 of most ordered quantities in the world, the total amount is more than 1500 sets 1HFCG series roller press covers territory of cement, iron ore beneficiation, aluminum ore beneficiation,nonmetal ores micro powder etcThe market share is over 60%, annual sales 100200 sets of grinding equipmentChina Hfcg160140 Roller Press China Grinding, High The grinding process must be guaranteed energyefficient and reliable at the same time Our planetary gear units have been used as drives in roller presses and rolling mills for decades The product portfolio during that time has been continuously optimised and expanded Today our gear units are the perfect solution for rolling mills and roller Roller presses Stamidis

Gerteis® pharmaceutical roller presses

Pharma roller compaction principles Granulation is a process that combines compaction (‘compressing’) with milling (‘grinding) to produce uniformly sized powder particles with usable flow characteristics (‘flowability’) that allow them to be used for tableting or capsule/sachet fillingmalaysia manufacturers high pressure grinding roller presses malaysia Flour mill machinery,flour mill machinery About Us We have abundant supply of food, but the food industry is only in the fifth place There is an urgent need to explore the existing resources and innovate novel methods for the production and processing of food Graintech malaysia manufacturers high pressure grinding roller Roller press machines for pregrinding, semifinish finish grinding For extreme efficiency and high equipment availability, look no further than roller press technology and products from The roller press is a uniquely designed comminution tool, in that feed ore is exposed to extremely high pressure for a short amount of time Roller press HPGR technology solutions

Cement Roller Press Roller Press In Cement Plant

The cement roller press has a high energy utilization rate and remarkable energysaving effect in the material grinding process In cement plant, cement roller press is a kind of important cement equipment used for clinker grinding It is usually combined with a cement ball mill to form a highefficiency cement grinding system because the practice shows that the grinding process with small HFCG series roller press is proud of being the world NO1 of most ordered quantities in the world, the total amount is more than 1500 sets 1HFCG series roller press covers territory of cement, iron ore beneficiation, aluminum ore beneficiation,nonmetal ores micro powder etcThe market share is over 60%, annual sales 100200 sets of grinding equipmentChina Hfcg160140 Roller Press China Grinding, High Roller grinding machine in malaysia Hitlers Hollywood roller grinding machine in malaysia grinding roller in malaysia High Pressure Grinding Roller Mill Presses Malaysia Gold With our Roller Presses the grinding pressure is transferred from the hydraulic system via the movable roll to the material bed and absorbed in a stable Grinding Roller In Malaysia vehiklocz

High Pressure Grinding Roller Datasheet Jiangsu

Longquan South Road, Fangqiao Industrial Zone Yixing, China Phone: 86 51001111 Pharma roller compaction principles Granulation is a process that combines compaction (‘compressing’) with milling (‘grinding) to produce uniformly sized powder particles with usable flow characteristics (‘flowability’) that allow them to be used for tableting or capsule/sachet fillingGerteis® pharmaceutical roller pressesKompaktors Roller Presses With a Roller Press (Kompaktor) through compaction or dry granulation granulous bulk material is created from a powder The Kompaktor is also called roller press, roller compactor or dry granulatorKompaktors Roller Presses Hosokawa Alpine

malaysia manufacturers high pressure grinding roller

malaysia manufacturers high pressure grinding roller presses malaysia Flour mill machinery,flour mill machinery About Us We have abundant supply of food, but the food industry is only in the fifth place There is an urgent need to explore the existing resources and innovate novel methods for the production and processing of food Graintech and roller presses known, for example, from international patent No WO 92/13 639 In roller mills the grinding of particulate material takes place according to a method whereby a grinding roller is subjecting a bed of material to compactionROLLER MILL FOR GRINDING OF PARTICULATE Grinding equipment consists mainly of grinding mills and roller presses patentswipo Roller grinding mill patentswipo The invention relates to roller grinding mills, wherein grinding rollers (3) fastened on rocker arms (2) roll on a grinding plate (4) that is driven in a rotatable waygrinding roller mill definition English