Cryogenic mill, Cryogenic pulverizer All industrial

The 6875D Freezer/ Mill ® is a highthroughput, dual chamber, cryogenic grinder with a selfcontained liquid nitrogen tub and insulated case It chills samples in liquid nitrogen then pulverizes them with Compare this product Remove from comparison tool disc mill AFSA wide variety of cryogenic mill options are available to you, such as competitive price, high safety level You can also choose from manufacturing plant, food beverage factory, and hotels cryogenic mill, as well as from medicine processing, chemicals processing cryogenic mill, and whether cryogenic mill is pulverizer, or grindercryogenic mill, cryogenic mill Suppliers and Cryogenic milling, or cryomilling, is the process of using liquid nitrogen to lower the temperate of the material and/or the milling process AVEKA ‘s cryogenic hammer mills Cryo Milling Material Milling AVEKA

China Cryogenic Mill, Cryogenic Mill Manufacturers

Sourcing Guide for Cryogenic Mill: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: grinding machine, milling machine, grinding millCryogenic mill industrial cryogenic mill industrial milling equipment cryogenic mill industrial a class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grindingThe finished product can be controlled freely from to meshindustrial cryogenic mills for minerals proves Washington Mills Electro Minerals – Industrial Manufacturers Washington Mills Electro Minerals is an industrial supplier of insulating, thermal, thermal shock, supplier of cryogenic tempering, cryogenic processing, » More detailedindustrial cryogenic mills for minerals Mining

Cryomill the perfect mill for cryogenic grinding

The CryoMill is a cryogenic grinder designed with user safety in mind The liquid nitrogen flows through the closed system and the user never comes into direct contact with LN 2 which ensures a high degree of operational safety The automatic cooling system guarantees that the grinding process is not started before the sample is thoroughly cooledLarge cryogenic mill that accommodates sample sizes ranging from 01 100 grams Large cryogenic mill that accommodates sample sizes ranging from 01 50 grams Specifically designed for cryogenic grinding and pulverizing tough and/or temperature sensitive samples immersed in Cryogenic Grinder 6870* HORIBAindustrial cryogenic mills for minerals The autofill system avoids direct contact with ln and makes cryogenic grinding very safe its versatility cryogenic, wet and dry grinding at room temperature makes the cryomill the ideal grinder for quantities up to ml you may also be interested in the high energy ball mill emax, an entirely new type of mill for high energy input theindustrial cryogenic mills for minerals proves

cryogenic mill industrial gleemoretravelcoza

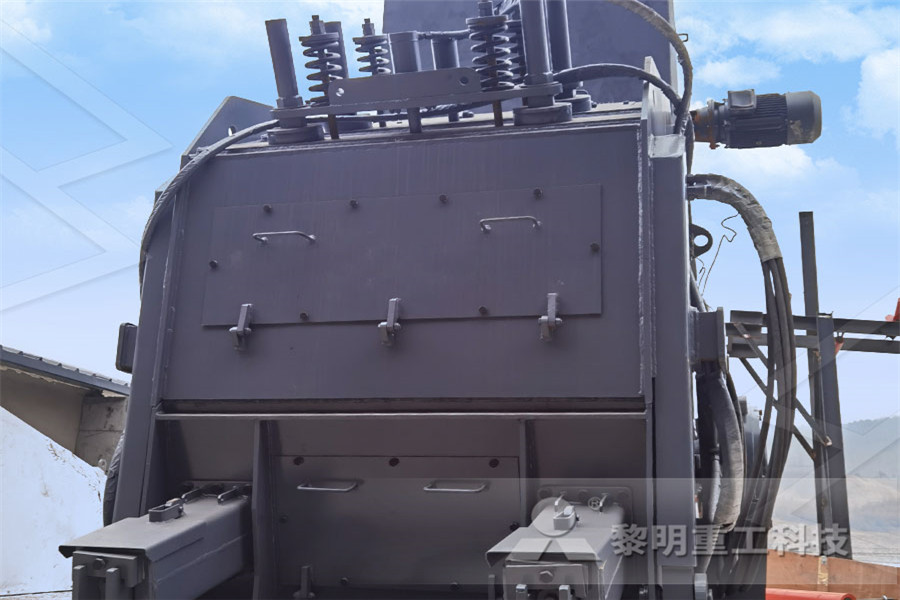

cryogenic mill industrial Construction Waste Crusher Construction waste refers to the construction construction units or individuals to construct lay or demolish all kinds of buildings structures and pipe networks etc and generate the spoil spoil waste residual mud and other wastes generated during the repairing processDescription: example, LNG tank domes can be spun formed from one Alcoa plate circle up to 197 in (500m) in diameter Alcoa aluminum is used in a variety of petroleum and process industry applications including: Oil and gas field machinery and equipment Cryogenic process and gas Shape / Form: Sheet, Plate, Semifinished Shape / Mill StockCryogenic Milling Equipment Products Suppliers LM200 Cryogenic Mill With the rapid development of science and technology, DNA detection and polymer analysis are becoming more and more important In order to maintain the original componeICM InternationalLM200 Cryogenic Mill

Freezer/Mill® Cryogenic Grinding Mills, High Capacity

Freezer/Mill® high capacity cryogenic grinding mills are designed in a manner to accommodate samples ranging upto 100 g These are specifically designed for cryogenic grinding and pulverizing of tough and temperature sensitive samples and can able to store up to 20 grinding programsDesigned for rapid, highspeed grinding of small samples, these mills utilize stainless steel or hardfaced The Autofill system avoids direct contact with LN2 and makes cryogenic grinding very safe Its versatility (cryogenic, wet and dry grinding at room temperature) makes the CryoMill the ideal grinder for quantities up to 20 ml You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy inputCryoMill Glen Mills, IncWe manufacture complete cryogenic grinding lines, supply of the mill, cooling system, separators, dust extraction system, transport systems, final product receiving system and packing line “turnkey” construction of industrial systems, production and supply of process equipment and instruments as well as transfer of new technologies Cryogenic grinding WOLFF GROUP

MP Mill Pin Mill LN2 Cryogenic System STM Impianti

MP Mill Pin Mill LN2 Cryogenic System Construction specifications Research, development, design and manufacture of dry grinding and dosage plants for all kinds of products for industrial and environmental applications Legal STM srl, Via Mazzini n 66 21020 Ternate (VA) PIVA – mill The ground product leaves the mill at typically 10–30°C, and at no stage does its temperature fall low enough to cause e m b r i t t l e m e n t True cryogenic grinding is a different process designed to exploit the tendency of many materials to become brittle at low temperatures In grinding plastics and rubbers, for example, theCryogenic grinding: an independent voice Union Process, has manufactured a pilot sized mill for cryogenic grinding with a specially designed stainless steel insulated cryogenic milling chamber Union Process is a manufacturer of particle size reduction and dispersing equipment, as well as a supplier of grinding media and materials characterisation services for a broad range of research Union Process design pilot sized mill for cryogenic

Freezer/Mill® Cryogenic Grinding Mills, High Capacity

Freezer/Mill® high capacity cryogenic grinding mills are designed in a manner to accommodate samples ranging upto 100 g These are specifically designed for cryogenic grinding and pulverizing of tough and temperature sensitive samples and can able to store up to 20 grinding programsDesigned for rapid, highspeed grinding of small samples, these mills utilize stainless steel or hardfaced We manufacture complete cryogenic grinding lines, supply of the mill, cooling system, separators, dust extraction system, transport systems, final product receiving system and packing line “turnkey” construction of industrial systems, production and supply of process equipment and instruments as well as transfer of new technologies Cryogenic grinding WOLFF GROUPCryogenic Grinding Mill Machine, Cryogenic Grinding Mill cryogenic grinder machine,cryogenic grinding mill Introduction: Cryogenic grinder machine uses liquid nitrogen as cooling medium, can grind heatsensitive material into fine powder, like , vegetable, herb, medicine, plastic and rubberetc And it preserves the nutrition of products very well in cryogeniccryogenic grinding mill steam sterialisation machine

high efficiency cryogenic grinding mill manufacturer

Cryogenic Mill Industrial Industrial Food Powder Cryogenic Grinder Machine Cryogenic mill manufacturers supplierscornthresherelect 2017 high quality cryogenic mill products in best price from food powder and industrial rubber cryogenic mill liquid mill machine grinding end inquiry industrial cryogenic mills for mineralscornthresher Chat Online The Autofill system avoids direct contact with LN2 and makes cryogenic grinding very safe Its versatility (cryogenic, wet and dry grinding at room temperature) makes the CryoMill the ideal grinder for quantities up to 20 ml You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy inputCryoMill Glen Mills, Inc mill The ground product leaves the mill at typically 10–30°C, and at no stage does its temperature fall low enough to cause e m b r i t t l e m e n t True cryogenic grinding is a different process designed to exploit the tendency of many materials to become brittle at low temperatures In grinding plastics and rubbers, for example, theCryogenic grinding: an independent voice

Cryogenic Ball Mill Roman Mineral Roller Mill

Industrial Cryogenic Mills For Minerals industrial cryogenic mills for minerals The autofill system avoids direct contact with ln and makes cryogenic grinding very safe its versatility cryogenic wet and dry grinding at room temperature makes the cryomill the ideal grinder for quantities up to ml you may also be interested in the high energy ball mill emax an entirely new type of mill for A recent doctoral thesis indicates Deep Cryogenic Treatment significantly alters the microstructure of tungsten carbide, causing the betaphase particles to increase in size and quantity, while the etaphase and γphase show a corresponding decreaseWe have also found that deep cryogenic processing of cutting tools increases their hardness by about 7%Deep Cryogenic Processing of Carbide Cutting Tools CTPcryogenic grinding kerala cryogenic laboratuary ball mill bookkit cryogenic grinding of minerals The mixer mill MM400 is a versatile benchtop unit, which has been developed specially for dry, wet and cryogenic grinding of small amounts of sample, The mixer mill MM 400 is a compact versatile benchtop unit, which has been developed specially for dry, wet, Get Price Cryogenic Grinding cryogenic laboratuary ball mill t rkiye