SAG Mill Liner Nanjing Manganese Manufacturing

Material for AG/SAG Mill Liners MGS Casting had success to use ASTM 2074/L2B alloy steel to manufacture AG/SAG mill liners Under this material, our mill liners span life can be obviously improved Our Australia customers had ordered more than 3000 tons per year of this material mill linersSemiautogenous grinding mill liner also called SAG mill liner, Autogenous grinding mill liner also called AG mill liner Since the 2014 year, HG Machineryhas had become one of the largest AG/SAG mill liner manufacturers from ChinaChina AG Mill Shell Liner factory and manufacturers A highlight of SAG milling has been the collaboration between grinding mill manufacturers and mining companies Experimental work on very large mills is difficult, expensive, and potentially catastrophic if it goes wrong, yet the work must be done if the mills SAG Mill Manufacturer 911 Metallurgist

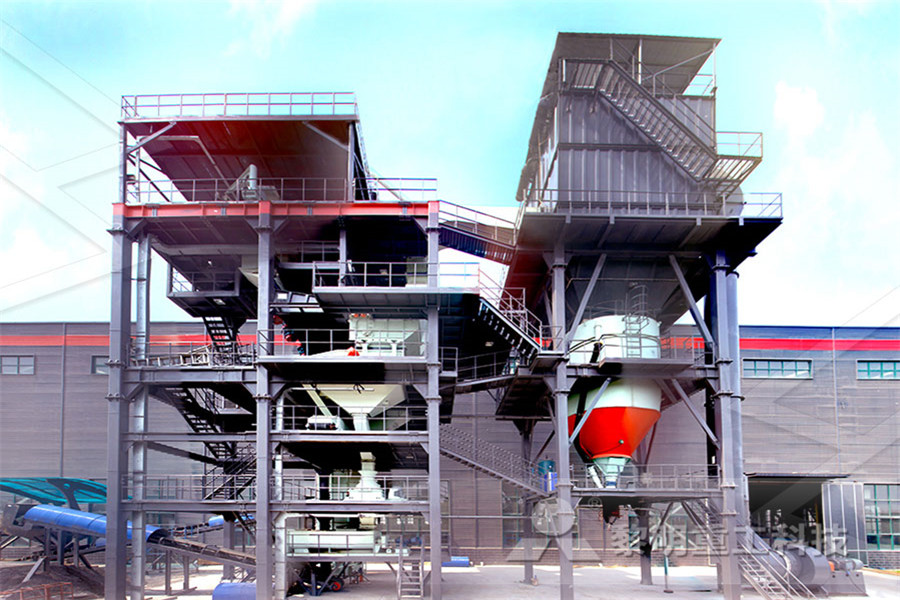

China Luoyang Hengin Heavy Industry Technology

Hengin is a global mining,cement,metallurgy,power and other fields of grinding,rotary equipment,girth gear and mining mill liner,crusher liner,cement rotary kiln idler and other products and system services provider Home / SAG Mill Liner / SAG Mill Liners Specification For Design And ManufactureWe manufacture complete or partial AGSAG mill revamping projects, casting of shell liner sets, head plates and grates We analyze working condition variables and propose our customers the alloy that will suit best their comminution process SAGAG mill inspection serviceSAG mill liner set pump impeller » Aceros y Suministros Manufacture of Liner Handler Machines of feathers with two booms, for SAG mill Ø 32'x 15 'long, with wristgrip Capacity 3000 kg each boom 2009Client: RIO MINAS BRAZIL Manufacture of Liner Handler Machines, for mill Ball Ø 26'x 42 REVESOL

VULCO Excellent Wear Resistant Linings Solutions

Mill liner experience and expertise Weir Minerals has considerable experience in the design and manufacture of linings for autogenous (AG) and semiautogenous (SAG) mills, primary, secondary, and regrind ball and rod mills Using a holistic approach, our experienced staff of engineers, designers, and chemists custom designTega Mill Linings provide optimal grinding solutions in major mineral processing plants all over the world Tega rubber lining system is the preferred lining system for secondary ball mills; regrind mills, rod mills and scrubberMill Linings Tega Industries Africa Pty Ltd It was reported that the site has increased gold recovery by 2%, increased SAG mill throughput by 1620%, improved liner service life by 40% and has reduced liner system replacement time by more than 60% Liner design has a dramatic impact on both mill availability and grinding efficiencyThe advantages of composite mill liners globalweir

WHAT MAKES US Growth Steel

The OptiLiner system can be made in full rubber or PolySteel to suit a variety of milling applications in Ball and SAG Mills A selection of fixing systems are available for each mill that best suit your method of installation and liner handler capabilities Reducing steel liner mill weight is often a challenge but with the OptiLiner systemHengin is a global mining,cement,metallurgy,power and other fields of grinding,rotary equipment,girth gear and mining mill liner,crusher liner,cement rotary kiln China Luoyang Hengin Heavy Industry Technology Mill Liners Manufacturer From China When it comes to mill liners, MGS Casting is a Chineseleading manufacturer of mill liners and trommels that improve grinding efficiency, reduce downtime, and lead to increased profitability, which specializes in the design, manufacture and aftersales service and support and is a proven provider of total mill lining solutions across the globeMill Liners Manufacturer From China

Mill and crusher liners Bradken

Bradken is a leader in the design, manufacture and supply of mill and crusher liners for primary and secondary applications in the global mineral processing and quarrying industries We offer our customers complete wear liner solutions for mills and crushers that increase performance, equipment availability and lower maintenance costs Design and Manufacture of Mill Liner Handler, model MEH4000 REVESOL, single boom, for Ball Mill, wrist grip capacity 4000kg 2012 Client: CODELCO CHILE/Salvador Project Chile Design and Manufacture of Mill Liner Handler, model MEH1600 REVESOL, single boom, for SAG Mill, wrist grip capacity 1600kg 2012REVESOL The OptiLiner system can be made in full rubber or PolySteel to suit a variety of milling applications in Ball and SAG Mills A selection of fixing systems are available for each mill that best suit your method of installation and liner handler capabilities Reducing steel liner mill weight is often a challenge but with the OptiLiner systemWHAT MAKES US Growth Steel

MINERAL PROCESSING Bradken

enous (SAG) grinding mills, having a significant impact on the throughput, efficiency and performance of mills Underestimating the importance of an optimised liner design in a mill can lead to backflow and carryover processes which can ultimately result in high wear, poor liner life and reduced mill Tega Mill Linings provide optimal grinding solutions in major mineral processing plants all over the world Tega rubber lining system is the preferred lining system Mill Linings Tega Industries Africa Pty Ltd Φ26m Rod Mill Liner Manufacture One of our customers had asked us to manufacture Nihard mill liner for his Φ26m Rod Mill Rod mill uses steel rods as the grinding media in tumbling mills is an efficient means to feed ball mills a product finer than could be made in a crusher but coarser than could be made in a ball millΦ26m Rod Mill Liner Manufacture Qiming Machinery

Mill Liner JinRuiDa Industry Solutions Co, Ltd

JinRuiDa Industry Solutions Co, Ltd Address: 300 HenDong Road Decheng Dezheou ShanDong China site: jrdindustrysolutions Tel: 86 It was reported that the site has increased gold recovery by 2%, increased SAG mill throughput by 1620%, improved liner service life by 40% and has reduced liner system replacement time by more than 60% Liner design has a dramatic impact on both mill availability and grinding efficiencyThe advantages of composite mill liners globalweirmanufacturers and suppliers of sag mill from around the world Panjiva uses over 30 international data sources to help you find qualified vendors of sag millSag Mill Manufacturers Suppliers of Sag Mill (Product

FC Mill Liners, Inc

become a principal suppler of cast iron and steel mill liners for AG, SAG, ball and rod mills in North America Proven Supplier FC Mill Liners in seven minutes Response Our commitment is to be a reliable supply chain partner of high quality mill liners, enous (SAG) grinding mills, having a significant impact on the throughput, efficiency and performance of mills Underestimating the importance of an optimised liner design in a mill can lead to backflow and carryover processes which can ultimately result in high wear, poor liner life and reduced mill MINERAL PROCESSING Bradken Inside view of Ball Mill Cast ball mill wave liners Forged mill ball production Mill Ball packing conveyor manufacture and supply of quality SAG, AG, ROD and BALL Mill components liners He has significant experience in all things milling and grinding encompassing mill liner concepts, detailed design, manufacturing, installation Milling Grinding – FFF Australia

The advantages of composite mill liners globalweir

It was reported that the site has increased gold recovery by 2%, increased SAG mill throughput by 1620%, improved liner service life by 40% and has reduced liner system replacement time by more than 60% Liner design has a dramatic impact on both mill availability and grinding efficiencyOur Intelligent Bolts provide the kind of real time liner wear information that mill operators and maintenance teams could only dream of until now Understanding the liner wear patterns and having accurate, predictive information can provide the corroborative or the critical data an operator needs to confidently schedule maintenance shutdowns Kaltech – The Global Leader in Mill RelinesHARCLIFF PTY LTD MTME is the Harcliff Mining Services exclusive distributor in Asia Pacific region Harcliff Mining Services is an acknowledged global specialist in the design, manufacture and refurbishment of new and existing equipment for the mining, minerals processing, pyro processing, cement, power generation and petrochemical sectorsManufacture of high performance, highquality mixer

Grinding Mills 911 Metallurgist

2 天前 Grinding Mills: Ball Mill Rod Mill Design Parts Common types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed here Photographs of a glass ended laboratory ball mill show action of ball Flow Control has become a separately listed independent company called Neles Neles is a flow control solutions and services provider for oil and gas refining, pulp, paper and the bioproducts industry, chemicals, and other process industries global website SAG mills are primarily used at gold, copper and platinum mines with applications also in the lead, zinc, silver, alumina and nickel industries The largest SAG mill is 42' in diameter, powered by a 28 MW (38,000 HP) motor AUTOGENOUS GRINDING MILL SAG They are socalled due to the selfgrinding of the oreMineral Processing SlideShare