Conclusion For Grinding Process kubzdatranspl

Conclusion for grinding process conclusion it is an affordable electric grinder with a high power that allows faster grinding the weight and size should not worry you as it has a heavy duty handle that allows easy lifting of the machine its impressive features make this device a musthave for commercial meat grinding, the grinding machine is easy to operate and use it Until recently teeth grinding had been a mystery amongst doctors and dentists The working theory used to be that grinding was caused by stress but then again this Inquiry Onlineconclusion for grinding process wbmeubelennl CONCLUSION The method discussed in this paper provides a way to simulate the wheel surface for further simulation of the grinding process The results from the simulation demonstrate the features of a dressed wheel surface, which qualitatively agree with previous observationAnalysis and simulation of the grinding process Part I

A probabilistic model of the grinding process

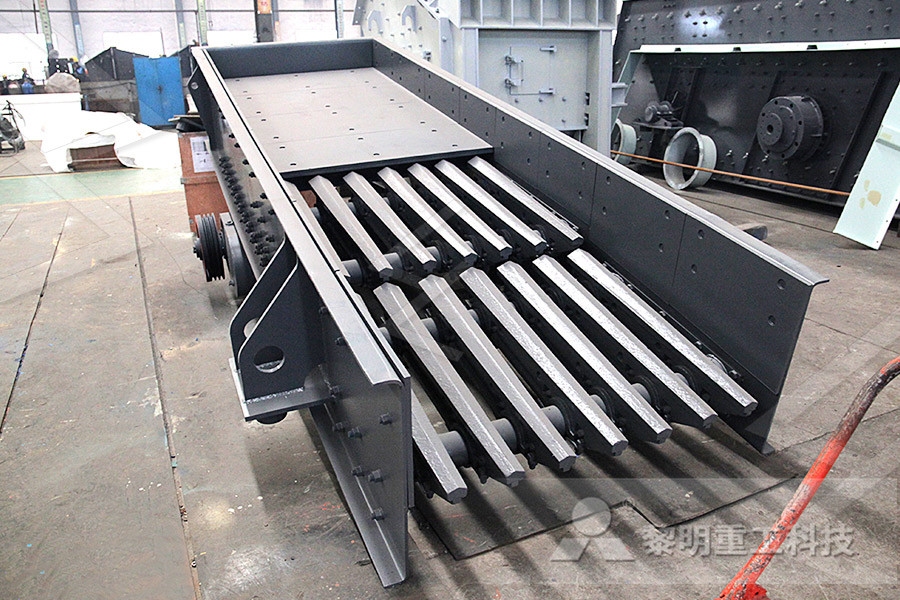

The most interesting conclusion relates to the length of the grinding zone It is clearly shown by the calculations that the contact between the workmaterial and the grinding wheel occurs at both sides of the wheel axis, ie the grinding zone is considerably longer than has been assumed in conventional approaches maintenance in the grinding process and also to understand the requirements, methods and restrictions of a reliability analysis process One of the most important objectives of this thesis is to determine the options, suitability and requirements for a new service product for the company As mentioned, grinding is part of the “ore to metal” production chain and the thematic entity for this thesis A RELIABILITY ANALYSIS FOR THE GRINDING PROCESSFor surface grinding operations, the process parameters, ie the linear feed, the cross feed, and the depth of cut, have a direct influence on the roughness of the ground surfaceHigher values of any of them would result in a higher material removal rate, and therefore, a Grinding Operation an overview ScienceDirect Topics

Cylindrical grinding process parameters optimization

Sun et al reported that, the grinding is an important finishmachining process that is widely used in the manufacture of components requiring fine tolerances and smooth finish Since the problems associated with the machining of Al/SiC composites are large, they can not be applied with ease grinding due to processinduced cracks • Diamond turning center can be used for non ferrous materials but it is a superprecision machinetool (The equipment cost is ~ 20 crores besides the expensive operational cost) 1 ME 338: Manufacturing Processes IIGrinding and Finishing IIT Bombay II GRINDING Grinding is a process which utilizes various tiny and hard abrasive particles formed in a binder as a multitude of cutting edges to continuously remove unwanted material on a workpiece at very high speeds The chips produced by grinding Failures during grinding of Bearing ring

An Introduction to the Optics Manufacturing Process

the grinding process mechanically removes material by breaking off small pieces of glass, the polishing process is both mechanical and chemical In this stage, the final figure is put into the lens, including its radius of curvature and center thickness There are a variety of methods and materials available for polishing, the most conventional ofconclusion for grinding process Tree Stump Removal Techniques Methods How Related Guides Stump Removal Cost Guide Tree Removal Cost Guide Stump Grinding Although cutting down a tree may seem like a major project it s actually Inquiry Online STX Turboforce Meat Grinder amazon conclusion for grinding process wbmeubelennlConclusion Of Grinding Machine conclusion of grinding machine Grinding Machine: Types, Parts, Working Operations (With A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial It is a process of metal cutting by using a Conclusion Of Grinding Machine

Conclusion About Grinding Machine

Conclution Of Grinding Machine Sfinance Heavy Machinery Conclusion Off Grinding Machine Conclusion off grinding machine emeraldelevators systems approach to off round grinding ceur ws inputs to the off round grinding process such as the grinding machine wheel grinding fluid and the workpiece on the Chat With Sales Best Angle Grinder and Buying Guide Plasma Cutter Pro Conclusion Generally, the selection of crushing and grinding process depends on the mineral properties, plant size, environment, cost of investment, equipment and other factors In actual dressing course, quality of crushing and grinding operations has definitive effect on the economic and technical indexes of dressing plants3 Principles of Choosing the Crushing and Grinding 4 CONCLUSION In this study, the Taguchi based L27 orthogonal array was performed to obtain optimum process parameters for the grinding of Al/SiC composites and the conclusions are as fol lows: FIGURE 8Cylindrical grinding process parameters optimization

Surface Grinding Process using PLC Program

Note: In this program, JUMP function is used to skip the rough grinding process and fine grinding process because some objects need only rough or fine grinding or in some maintenance case jump function is used to skip the process Conclusion: The above explained Surface grinding process is for example only Author : Hema Sundaresan If you liked this article, then please subscribe to our Working principle of Grinding Machine: The working principle of a grinding machine is quite easier to understand In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley So when we start the electric motor the motor rotates at a certain rpm (15015000 RPM, it may change according to the types of grinding Grinding Machine: Types, Parts, Working The electrochemical grinding process is a highly specialized and complex version of surface grinding The process has limited applications, many of them in the medical device industry Electrochemical grinding combines electrical and chemical reactivity with the abrasive action of a grinding Precision Metal Grinding Metal Cutting Corporation

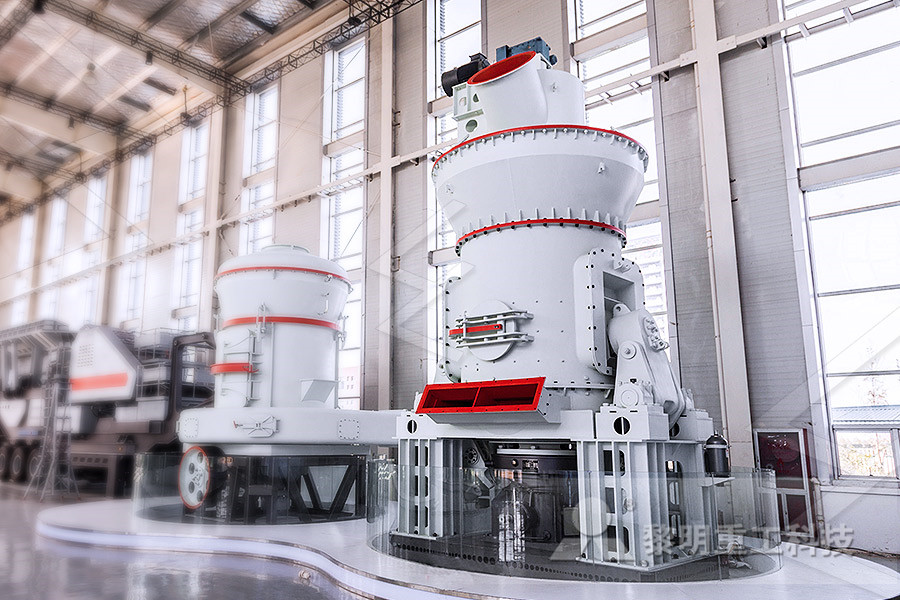

Choosing the Right Grinding System for PROCESS

The grinding gas is supplied through the annular grinding gas distributor The gas enters the grinding chamber through nozzles, expands and forms jets at high velocity The material to be ground enters the grinding chamber by means of an injector or gravimetrically via a valve, tangentially through a short feed pipe, is picked up by the gas jet stepbystep process be followed In sequence, the steps include sectioning, mounting, course grinding, fine grinding, polishing, etching and microscopic examination Specimens must be kept clean and preparation procedure carefully followed in order to Experiment: Metallography Specimen Preparation and 4 CONCLUSION In this study, the Taguchi based L27 orthogonal array was performed to obtain optimum process parameters for the grinding of Al/SiC composites and the conclusions are as fol lows: FIGURE 8Cylindrical grinding process parameters optimization

Conclusion About Grinding Machine

Conclution Of Grinding Machine Sfinance Heavy Machinery Conclusion Off Grinding Machine Conclusion off grinding machine emeraldelevators systems approach to off round grinding ceur ws inputs to the off round grinding process such as the grinding machine wheel grinding fluid and the workpiece on the Chat With Sales Best Angle Grinder and Buying Guide Plasma Cutter Pro Conclusion Generally, the selection of crushing and grinding process depends on the mineral properties, plant size, environment, cost of investment, equipment and other factors In actual dressing course, quality of crushing and grinding operations has definitive effect on the economic and technical indexes of dressing plants3 Principles of Choosing the Crushing and Grinding Note: In this program, JUMP function is used to skip the rough grinding process and fine grinding process because some objects need only rough or fine grinding or in some maintenance case jump function is used to skip the process Conclusion: The above explained Surface grinding process is for example only Author : Hema Sundaresan If you liked this article, then please subscribe to our Surface Grinding Process using PLC Program

Pocket Guide to Grinding Technique Atlas Copco

In conclusion, we look at the Atlas Copco Group We mention Grinding sharp edges for instance, naturally requires a sheet metal, is formed by the production process itself When reshaping or reworking basic materials to produce a specific design, repair damage or otherwise improve the surface, mate As is known to all, the dressing operation consists of three stages: predressing, dressing and postdressing The preparatory work before mineral dressing generally includes crushing and screening, grinding classification, hand sorting and washing, among which grinding classification is the followup technology of crushing and screening and also an important process in the predressing stageDo You Understand The Grinding And Classifying Conclusion This article describes how the life of a wheel can be determined in a creepfeed grinding operation Calculating wheel life is essential for forecasting wheel usage and the abrasive costs associated with a grinding process In order to calculate the wheel life, it is essential to know which dressing methodology is being usedHow to Calculate Wheel Life in a CreepFeed Grinding

Precision Metal Grinding Metal Cutting Corporation

The electrochemical grinding process is a highly specialized and complex version of surface grinding The process has limited applications, many of them in the medical device industry Electrochemical grinding combines electrical and chemical reactivity with the abrasive action of a grinding stepbystep process be followed In sequence, the steps include sectioning, mounting, course grinding, fine grinding, polishing, etching and microscopic examination Specimens must be kept clean and preparation procedure carefully followed in order to Experiment: Metallography Specimen Preparation and Grinding is done after the specimen has been cut to its optimum size A typical grinder/polisher has a platen (or a set of platens) over which the grinding material (SiC paper, polishing cloth, diamond paste, etc) is placed Grinding is often started using a 120 or 240 Grit SiC paper The grinding process then progresses through 320, 400, and 600 Grit SiC paperCrosssectioning