india mechanical can crusher design domyrolmexpl

mechanical pdf in india populareducationcoza Design and Development of a Plastic Bottle Crusher International Management, Katol Road, Nagpur, Maharashtra, India Abstract—A crusher is a force amplified by mechanical advantage through a material made of molecules plastic bottle crusher that is portable and can get price 3Assistant Professor, Department of Mechanical Engineering, Nehru Institute of Technology, Coimbatore, Tamilnadu, India A B S T R A C T At present can is being crushed manually which employs more time and more man power This can crusher can crush the aluminium can and an operator is required to handle the machine during the crushing processDESIGN AND FABRICATION OF CAN CRUSHING design Thus with the help of this design we can fabricate an automatic can crusher machine to simply reduce the volume of cans as well as to reduce the human fatigue Also the automatic operation can be possible using the mechanical power transmission operated by Design and Fabrication of Can Crusher ijirset

(PDF) DESIGN OF MECHANICAL CRUSHING MACHINE

Can crusher machine using scotch yoke mechanism IOSR Journal of Mechanical and Civil Engineering pp 6065 [6] A Elfasakhany, J Marquez, EY Rezola, J Benitez (2012) Design and Development of An Economic Autonomous Beverage Cans Crusher International Journal of Mechanical Engineering and Technology Volume 3, Issue 3, pp107122 do and fabricating the Tin Can Crusher to helps people easy to crush the tin and bring anywhere This project involves the process of designing the crusher using considering forces and ergonomic factor for people to use After the design has complete, it was transformed to its real product where the design is used for guide the safety forDesign and Fabrication of Tin Crusher increase That why we choose this project is about design and fabrication of double acting crushing machine is a mechanical can crusher to help people to crush the tins easily handling and installed anywhere with their compact shape and size Now a days there is a widely usage ofDESIGN AND FABRICATION OF THE DOUBLE ACTING

PNEUMATIC CAN CRUSHER

PNEUMATIC CAN CRUSHER Bhavik Ranjan Kathe MECHANICAL ENGINEERING DEPT, PILLAI HOC COLLEGE OF ENGINEERING AND TECHNOLOGY, UNIVERSITY OF MUMBAI, KHALAPUR, MAHARASHTRA, INDIA***Abstract The Can Crushing process is a main part of the Wastage Collecting industries Normally the Can Crushing machine is manually hand operated It can be placed everywhere, in the park, houses, even incurs, by using a smaller can crusher Therefore, this project interest and expose me the field of mechanism and design Engineering To design the mechanical part of a can crusher and to fabricate the Mechanical part of the systemHand Operated Can Crusher mechanical project Full concept of can crusher that would make easier to bring anywhere and easier to crush cans After design has completed, it was transformed to its real product where the design is use for guidelines II Literature Review Kevin W Schell etal 2002: The electric aluminum can crusher is an appliance for crushing aluminumFabrication of Aluminium Can Crusher by Hydraulic System

Design and Fabrication of Can Crusher 1Library

Thus with the help of this design we can fabricate an automatic can crusher machine to simply reduce the volume of cans as well as to reduce the human fatigue Also the automatic operation can be possible using the mechanical power transmission operated by electric motor or electric actuator etc Design and Development of Aluminium Can Crusher Yashwant Attarde1, Pushpender Singh2, Mahendra Patil3, Avinash Patil4, Ganesh karpe5 1,2,3,4Student, Department of Mechanical Engineering, Savitribai Phule Pune University (SPPU), Pune, India 5Assistant Professor, Dept of Mechanical Engineering, Savitribai Phule Pune University (SPPU), Pune, IndiaDesign and Development of Aluminium Can Crusher DESIGN OF MECHANICAL CRUSHING MACHINE Senthil KannanN1, 2Naveen PrasadD2, Nirmal KumarR2, PremvishnuRS 1 Assistant Professor, Dept of Mechanical Engineering, Sri Ramakrishna Engineering College, Tamil Nadu, India 2 UG Student, Dept of Mechanical Engineering, Sri Ramakrishna Engineering College, Tamil Nadu, IndiaDESIGN OF MECHANICAL CRUSHING MACHINE

Can Crusher SlideShare

Can Crusher 1 1 Synopsis Report On Can Crusher Submitted in partial fulfillment of the Requirements for the award of the degree Of BACHELORS OF ENGINEERING In MECHANICAL ENGINEERING Submitted By: Submitted To: Ankit Kumar (14BME8011) Mr Harpreet singh Gorya Akshay kumar(14BME8004) Lalit Soni(14BME8036) UNIVERSITY INSTITUTE OF ENGINEERING CHANDIGARH UNIVERSITY GHARUAN, MOHALI, PUNJAB, INDIA DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER Thesis submitted in partial fulfillment of the requirements for the degree of Bachelor of Technology (B Tech) In Mechanical Engineering By DEEPAK GUPTA Roll No: 107ME037 Under the Guidance of PROF N KAVI NATIONAL INSTITUTE OF TECHNOLOGY ROURKELA , INDIADESIGN AND ANALYSIS OF A HORIZONTAL SHAFT PNEUMATIC CAN CRUSHER Bhavik Ranjan Kathe MECHANICAL ENGINEERING DEPT, PILLAI HOC COLLEGE OF ENGINEERING AND TECHNOLOGY, UNIVERSITY OF MUMBAI, KHALAPUR, MAHARASHTRA, INDIA***Abstract The Can Crushing process is a main part of the Wastage Collecting industries Normally the Can Crushing machine is manually hand operated PNEUMATIC CAN CRUSHER

A Novel Development of a Manual Can Crusher by V

The can crusher will be made up of various parts containing as part of the whole being considered a lever, base frame, can bin, piston cylinder arrangement, chain sprocket mechanism and bearing The inspiration behind this design came from the wastage in malls, canteens of big company often the holidays involve large parties where people gather The Design engineer is responsible for Reverse engineering of Crusher, SAG, Ball mills products to create CAD models from scanned data using softwares such as Geomagic, Spaceclaim, Mesh2surface Independently lead scan processing projects using reverse engineering method for crusher Design Engineer Mechanical(Reverse Engineering Job description: The Design engineer is responsible for Reverse engineering of Crusher, SAG, Ball mills products to create CAD models from scanned data using softwares such as Geomagic, Spaceclaim, Mesh2surface Job Role Responsibilities: Independently lead scan processing projects using reverse engineering method for crusher mill productsDesign Engineer – Mechanical(Reverse Engineering)

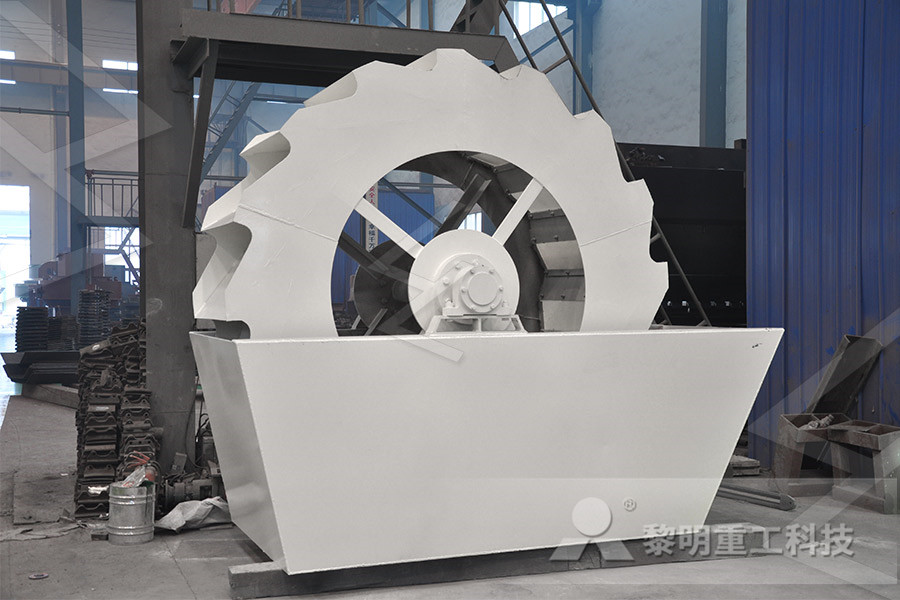

Design and Development of Plastic Recycle Machine

Vol3 Issue2 2017 IJARIIE ISSN(O) 2395 4396 4084 ijariie 490 Design and Development of Plastic Recycle Machine Kamesh B Vaidya, Mayank N Kosurkar, Rajesh B Pole, The project is about fabrication of mechanical crusher which would help to crush the used juice cans, paint cans and punched sheet metal waste This paper aims Todesign a crusher that could be installed anywhere and would aid crush of used wastes This paper involves the process of designing the crusher considering forces required for crushing and ergonomic factor that an operator needsREVIEW ON DESIGN AND FABRICATION OF CAN CRUSHING 2Assistant Professor, Mechanical Engineering, VVCE, Karnataka, India Email: 1 rdarshanmysore@gmail, 2 Abstract The paper is about design of a Plastic Bottle Crusher which would help to crush the used Plastic bottles andiraj DESIGN AND FABRICATION OF CRUSHER

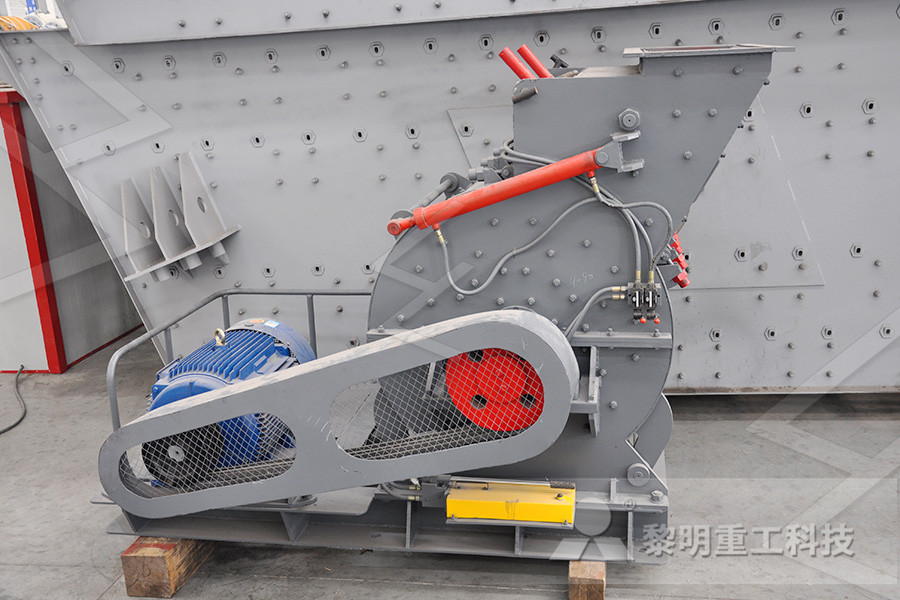

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

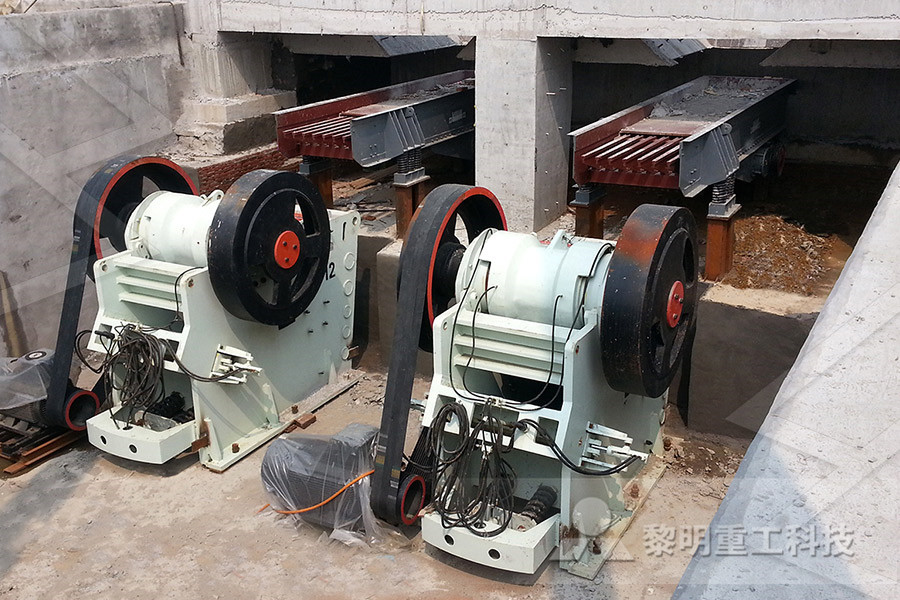

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER Thesis submitted in partial fulfillment of the requirements for the degree of Bachelor of Technology (B Tech) In Mechanical Engineering By DEEPAK GUPTA Roll No: 107ME037 Under the Guidance of PROF N KAVI NATIONAL INSTITUTE OF TECHNOLOGY ROURKELA , INDIAIndia Portable Crusher And Screening Units portable crusher unit india For some specific situations you can operate with 2 stage that consists of jaw cone crusher and plant that performs screening india portable crusher and screening small crusher and screener unit in india small mobile concrete crushing and screening units australia small aggregate Harison Jaw Crusher is mobile crawler small design india crusher plantProject Report For Clay Brick Making Business In India Crusher News Project report for clay brick making business in indiaThe project objective is to setup a clay brick processing plant in indiaThe plant would process cut to predefined sizes and polish raw clay brick blocks and produce clay brick stripstiles and slabsIn india, there is a great demand for a fully equipped clay Project Report For Clay Brick Making Business In India

(PDF) Design and Development of a Plastic Bottle Crusher

—A crusher is a machine designed to reduce large solid material objects into a smaller volume, or smaller pieces Crushers may be used to reduce the size, or change the form, of materials so they can be more easily and efficiently used in the purposeDesign Engineer – Mechanical(Reverse Engineering) Valbrid Engineering and Technologies Private Limited Chennai, Tamil Nadu, India 10 minutes ago Be among the first 25 applicantsDesign Engineer – Mechanical(Reverse Engineering) The can crusher will be made up of various parts containing as part of the whole being considered a lever, base frame, can bin, piston cylinder arrangement, chain sprocket mechanism and bearing The inspiration behind this design came from the wastage in malls, canteens of big company often the holidays involve large parties where people gather A Novel Development of a Manual Can Crusher by V Anusha

Eloquent Technology Manufacturer from Byraveshwara

Eloquent provides Product Design and New Product Development Services for commercial, Mining and Industrial Products, as well as the Custom Machine Design of Manufacturing Tools or Manufacturing Automation to create those products We have a vision to provide complete Mechanical Engineering Design Services for the following:Design And Development Engineer GK Group Swami Samarth Industries June 2014 – July 2016 2 years 2 months Nasik Area, India • Designed various mechanical components for automotive and Rohan Aher Mechanical Design Engineer BENLEE LinkedIn