Mill Circulation Factor International Cement Review

Subscribe to International Cement Review 12 issues of the leading cement industry magazine, your choice of complimentary handbook, plus unlimited access to CemNet News, Articles and HD Videos £ 205 / US$ 315 / EUR 74 Sinoma reduces pressure differential and power consumption at a cement plant in Guizhou province, China, with its external circulation technology for raw meal grinding When the VRM system evolved from an entirelyinternal material circulation process to a partiallyexternal circulation External circulation technology for VRM raw meal For grinding coal, slag, cement, etc, adaptations to mills and systems have to be flow rate must be selected to achieve a dust load of 500 600 [g/m 3 ] raw gas speeds wider PSD, resp steeper or flatter slopes in the RRSBchart 63 Partial Load The tendency in modern cement plant concepts is to adapt the raw millflow daigram of raw mill in cement plant

raw mill circulation cement plant mepsystemfr

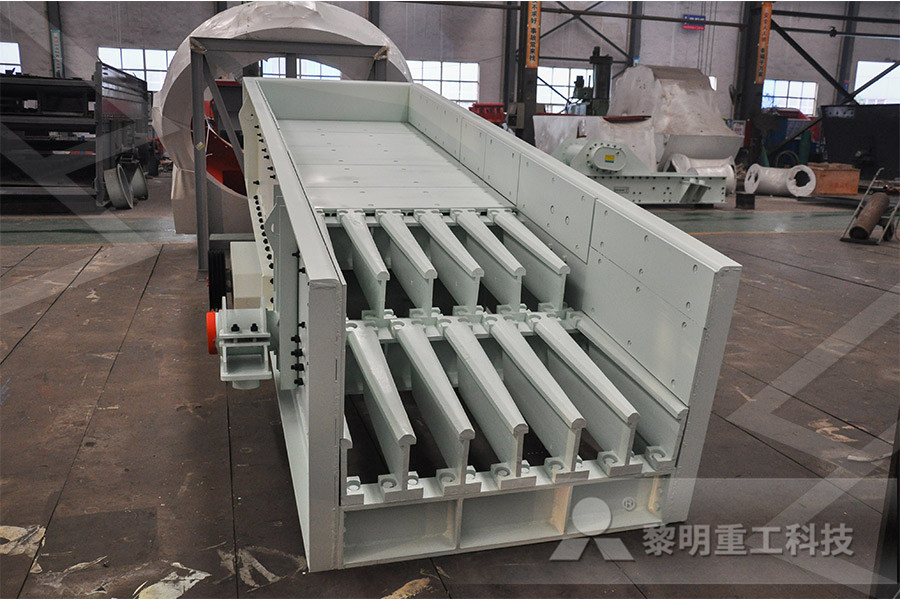

raw mill circulation cement plant The ATOX Raw Mill is a highly efficient mill that grinds all types of raw materials saving both space and energy while delivering outstanding performance Live Chat Model main object clause of more than 500 types of 6 Proportional feeding of raw mill (Weigh Feeder) 7 Raw mill circulation (Bucket Elevator) 8 Filter dust reclaim (En Masse Chain Conveyor) 9 Raw meal silo feeding (Bucket Elevator) 10 Reception and transfer of ®alternative fuels (Samson Feeder) 11 Raw meal feeding to preheater (Bucket Elevator) 12 Clinker dust reclaim (En MasseConveying and Storing in the Cement IndustryThe plant is a single chamber mill with mechanical circulation system which grinds a medium hard material at a capacity of about 160 tons/h Raw Mix Preparation ABB Ltd For cement raw material preparation, our renowned raw mills with the proven Almost any plant for the grinding of cement raw material is a combination of The iron oxide cement plant raw mill mpdistributionfr

Thermodynamic Performance Analysis of a Raw Mill

The exergy destruction rate and exergetic performance of the raw mill system in the cement plant were calculated to be 2940 kW and 3467%, respectively In addition, the system design parameters that affected the process performance, such as the ambient temperature, mass flow rate, and component temperature, were analyzed The raw mill considered in this study is located in a cement plant located in Sanliurfa, Turkey The plant is a single chamber mill with mechanical circulation system which grinds a medium hard material at a capacity of about 160 tons/hReducing energy consumption of a raw mill in cement Raw Mill Circulation Cement Plant cemWHR 2020 will help to promote WHR implementation in the Indian Cement industry Encourage utilities that utilises the waste heat available to generate power and thereby reducing operating costRaw Mill Circulation Cement Plant Trinity Trade

selection of raw mill for cement plant in Turkey

The Mill Of Cement Jun 01 The raw mill considered in this study is located in a cement plant located in Sanliurfa Turkey The plant is a single chamber mill with mechanical circulation system which grinds a medium hard material at a capacity of about 160 tonsh The mill Raw material mill recirculation fan plays a big role in cement raw material mill system, it can control the following parameters of mill system by adjusting the circulation fan: Industrial Fans and Blowers for Cement Plant 1 Airflow in raw material mill: vertical mill Cement Raw Material Mill Recirculation Fan by Xianrun Blower Raw material mill, also called raw meal mill, is important grinding equipment in cement production process After being crushed, the raw meal enters the raw material mill The raw meal is grinded into fine powder by the motion and squeezing of steel ballsRaw material mill Cement Mining Equipment

Raw material mill GGBSCement Plant,cement

Raw material ball mill, also called raw meal ball mill, is important grinding equipment in cement production process After being crushed, the raw meal enters the raw material mill The raw meal is grinded into fine powder by the motion and squeezing of steel balls The raw material mill manufactured by Great Wall Machinery can meet the raw material supply of 250~2500t d Sinoma reduces pressure differential and power consumption at a cement plant in Guizhou province, China, with its external circulation technology for raw meal grinding When the VRM system evolved from an entirelyinternal material circulation process to a partiallyexternal circulation process, the pressure differential and gas volume were External circulation technology for VRM raw meal Changshan South Cement, China benefitted from a costsaving energy retrofit of its two clinker production lines with MC2x39No305F raw mill circulation fans Holcim Cement Fan Retrofit This case highlights Howden’s ability to help its cement customers maximise the efficiency of their fans with a customised designCement Production Cement Howden

Raw Mill, रॉ चक्की क्लासीफियर in Arakkonam ,

The ATOX® raw mill uses pressure and shear generated between the rollers and the rotating table to crush and grind raw materials Feed material is directed onto the grinding table by the feed chute The rotation of the grinding table accelerates the material towards SINOMALY provides various types of Cement Mill, Clinker Mills, which are designed for use in grinding mill production lines with output levels of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d, 8000t/d Cement pregrinding is a production process used to grind raw material to a specified size so that it can be more easily processed by a final Cement Mill Vertical Mill Manufacturer SINOMALYRecirculation provision is always available in silos to recirculate raw meal during kiln shutdown or any inactive period to avoid internal buildups Therefore, it is recommended to do periodic (12 years) internal inspections and maintenanceHomogenization (BLENDING) Cement Plant

structure of roller mill of cement plant

structure of roller mill of cement plant Operation Guide for Vertical Roller Mill in Cement Plant The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy Raw material mill, also called raw meal mill, is important grinding equipment in cement production process After being crushed, the raw meal enters the raw material mill The raw meal is grinded into fine powder by the motion and squeezing of steel ballsRaw material mill Cement Mining Equipment Changshan South Cement, China benefitted from a costsaving energy retrofit of its two clinker production lines with MC2x39No305F raw mill circulation fans Holcim Cement Fan Retrofit This case highlights Howden’s ability to help its cement customers maximise the efficiency of their fans with a customised designCement Production Cement Howden

animation of raw mill in cement plant skladterlickocz

Raw Mill In Cement Plant,Cement Making Plant This paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder This is achieved in a cement role of raw mill in cement plant Cement Raw Material The end customer is the Egyptian Cement for Cement Projects Management SAE The planned new plant is located nearly 500 km south of Cairo in Sohag The LOESCHE scope of delivery includes a raw material mill with a capacity of 540 t/h of cement raw meal, a cement mill with an output of 350 t/h of clinker as well as a coal mill with an output about raw mill in cement plant,bangunan crusher Raw Mill Fan Dunbar Cement At Tarmac (Dunbar cement plant, UK), their existing Raw Mill fan was replaced with an enhanced Howden design in 2007 Changshan New Fan Changshan South Cement, China benefitted from a costsaving energy retrofit of its two clinker production lines with MC2x39No305F raw mill circulation fans Cement Centrifugal FanCase Studies Howden

Raw Mill, रॉ चक्की क्लासीफियर in Arakkonam ,

The ATOX® raw mill uses pressure and shear generated between the rollers and the rotating table to crush and grind raw materials Feed material is directed onto the grinding table by the feed chute The rotation of the grinding table accelerates the material towards Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity millsRaw Material DryingGrinding Cement Plant Pfeiffer MPS 4250 B roller mills as replacements Each mill is designed to achieve a capacity of 200t/hr of cement raw material ground to a fineness of 12% R90µm The drive power per mill is 2250kW Gebr Pfeiffer will also supply the complete equipment for the external material circulation system as well as the cyclone collectors and mill fansHeidelbergCement’s Burglengenfeld cement plant to

Homogenization (BLENDING) Cement Plant

Recirculation provision is always available in silos to recirculate raw meal during kiln shutdown or any inactive period to avoid internal buildups Therefore, it is recommended to do periodic (12 years) internal inspections and maintenance the mill, thus ensuring a comfortable mill stability margin It also offers a competitive, simple, and proven solution to cement producers willing to capture new and potentially changing markets in the fastest way Conclusion Whether considering raw meal grinding, cement grinding, or slag grinding, the FCB Horomill plantTeresa plant, the Philippines: cement grinding plant