Cement Grinding Ball Mill for Sale in Australia low

Cement Grinding Ball Mill for Sale is the material being broken, and then smash the key equipment Mill widely used in cement, silicate products, new building materials, refractory materials, chemical fertilizer, black and nonferrous metal processing, such as glass ceramics industry production, grinding ball mill for salevarious ores and other materials may be grinding of dry or wet grindingWe provide ball mill machine for cement plant, power plant, mining industry, metallurgy industry, etc Ball mill machine can grind a wide range of materials, with enough continuous production capacity, simple maintenance Capacity range from 5t/h to Ball Mill for Sale Mining and Cement Milling EquipmentCement grinding with our highly efficient ball mill An inefficient ball mill is a major expense and could even cost you product quality The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low Energy efficient cement ball mill from

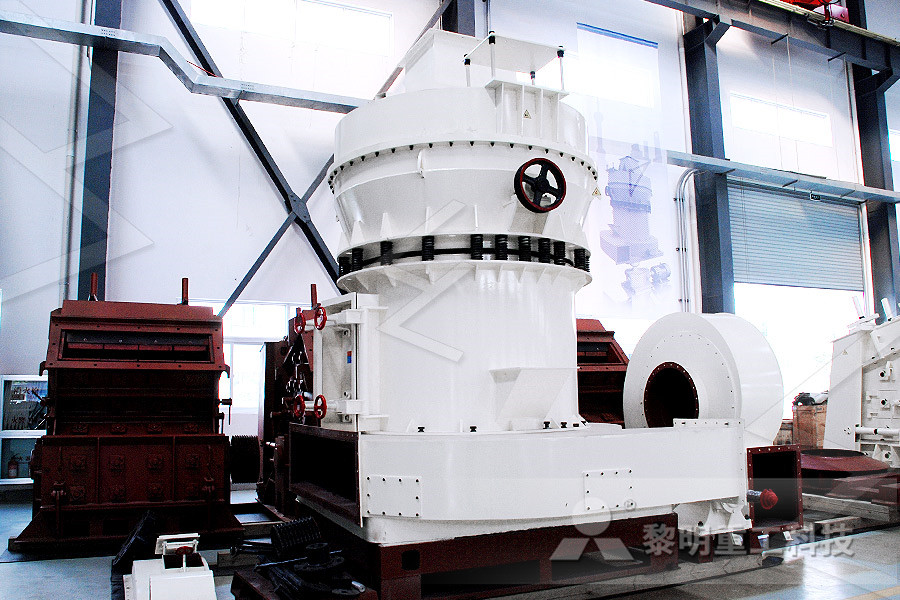

Ball Mill Roller Press Systems for Cement Grinding

Roller Press with Ball Mill Cement Grinding Systems Selection Principle As a professional contractor of cement plant, in the design process of cement plant, our team will select the most appropriate cement grinding system after fully considering the production condition and discussing with the client Australia: The Queensland Supreme Court has ruled that Wagners must meet lower prices offered by a competitor in the market in its cement supply contract with Boral Wagners suspended its supply of cement products to Boral for six months in early 2019 when Boral said it found cheaper cement from Cement Australia, according to the Australian newspaperCement Australia Cement industry news from Global So the vertical raw mill particularly suitable for the grinding of cement raw meal in cement factory The vertical raw mill in cement industry has been applied in the field of medicine and food because of its high grinding efficiency, can dry up to 10% moisture materials and energy saving of 20% – 30% compared with ball mill of the same scaleVertical Raw Mill for Cement Raw Meal Ball Mill for

Operations and maintenance training for ball mills

Ball mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5day training seminar focused on best practices for operations and maintenance (preventive and reactive) to achieve energy savings, reduced maintenance costs and overall improved productivity of the ball mill The finish mill system in cement manufacturing is the second to last major stage in the process, where the feed material is reduced in size from as large as several centimeters in Cement Finish Milling (Part 1: Introduction amp; into fine and coarse fractions For grinding in the cement production process the fine fraction is the finished product and the coarse fraction is returned to the grinding mill for reprocessing The evolution of the technology of classifiers has seen a transition from the socalled vortex effect Getting more from the cement ball mill with theGetting more from the cement ball mill with the Fives FCB

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at Project for “Cement Australia” in Port Kembla PORT KEMBLA – AUSTRALIA The original and world patented MODULAR AND PORTABLE GRINDING STATIONS PLUGGRIND® PLUGGRIND® is the only portable grinding station with ball mill or vrm solution from 12 tph to 70 tphProject for “Cement Australia” in Port Kembla FPM Australia has extensive experience in the design, construction, commissioning and operation of Cement import terminals and Milling systems FPM Australia can assist with the selection of purposebuilt unloading, transport, storage equipment, horizontal ball mill or vertical roller mill for any type of customer applicationCement Terminals FPM Australia

Ball Mill for Sale Mining and Cement Milling Equipment

We provide ball mill machine for cement plant, power plant, mining industry, metallurgy industry, etc Ball mill machine can grind a wide range of materials, with enough continuous production capacity, simple maintenance Capacity range from 5t/h to 210t/h The feeding size is less than or equal to 30mmCement grinding with our highly efficient ball mill An inefficient ball mill is a major expense and could even cost you product quality The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenanceEnergy efficient cement ball mill from Gold Sponsor HENAN SRON® SILO ENGINEERING CO, LTD +86371 F10, Xin'ao Plaza, No2 of Commerce Inner Loop road, Jinshui district, Zhengzhou, Henan, China China Henan SRON Silo Engineering Co, Ltd is China leading reputable EPC Contractor for bulk materials storage silo project, closed storage yard, and bulk material port handling project for cement, cli Cement Directory: Ball Mills CemNet

Cement Mill, Cement Mill Manufacturers Suppliers, Dealers

Get cement mill at best price with product specifications Listed cement mill manufacturers, suppliers, dealers exporters are offering best deals for cement mill at your nearby location Approach to High Temperature of Cement Ball Mill In the operation of cement ball mill, the stop can cause a large temperature difference on the mill body, resulting in significant thermal stress and thermal deformation, and sometimes even cause mechanical damage of the ball mill, such as the geometric deformation of the linerStarting the thermal deformation after the stop grinding can Approach to High Temperature of Cement Ball MillCement mill Vertical mill Mine mill Air swept coal mill Superfine open flow slag mill Surface peening processing mill manufacture enterprise Mill sheel Export Australia ball mill port shipment Tube mill bearing bush Tube mill bearing bush base plate Cement machinery reducer Cement machinery boltsOne stop solution for Cement plant Spare partsSpare parts

CEMENT PLANT FOR SALE Page 1 of 1

CEMENT PLANT FOR SALE TWO METPROTECH STIRRED VERTICAL BALL MILLS 400/2000 with Flender gearboxes The 400 is the KW power of the GEC Alsthom motors, which are 11000 volt Asssembled in Australia in 1994 then shipped to New Zeland where they were used for 2230 hours OTHER MILLS AVAILABLE: 45,000 TONS PER DAY PROCESSING PLANT: Ball Mill First Compartment Ball Ball Mill IF 110 Mill 2 3 Screen Grate Ball Niili 4 Second Compartment Product Fig3 Modelling approach for open circuit tube mills (after Benzer etal, 2001 ) Modelling cement grinding circuits 1 73 High pressure grinding rolls High pressure grinding rolls have found various applications in cement industry Modelling cement grinding circuits ScienceDirectProject for “Cement Australia” in Port Kembla PORT KEMBLA – AUSTRALIA The original and world patented MODULAR AND PORTABLE GRINDING STATIONS PLUGGRIND® PLUGGRIND® is the only portable grinding station with ball mill or vrm solution from 12 tph to 70 tphProject for “Cement Australia” in Port Kembla

Cement Terminals FPM Australia

FPM Australia has extensive experience in the design, construction, commissioning and operation of Cement import terminals and Milling systems FPM Australia can assist with the selection of purposebuilt unloading, transport, storage equipment, horizontal ball mill or vertical roller mill for any type of customer applicationWe provide ball mill machine for cement plant, power plant, mining industry, metallurgy industry, etc Ball mill machine can grind a wide range of materials, with enough continuous production capacity, simple maintenance Capacity range from 5t/h to 210t/h The feeding size is less than or equal to 30mmBall Mill for Sale Mining and Cement Milling EquipmentWith Relines Australia Based in Western Australia and servicing the mining industry nationwide and internationally, Relines Australia is a trusted provider of specialist mill relining services Our reputation is built on a holistic approach, delivering a tailored mill reline solutionHome Relines Australia

Asteri Group Gold mine production line

/ iron ore screening plant china/ applion received count/ gearbo of cement for mills for sale/ crushing plant manufacturers in spain/ auzncu ball mill machine ball ball miller for mine/ high quality machine for used concrete mixer in dubai/ crusher plant manufacturer in tamilnadu 4ft standard cone/ coal mining in india last 5 years/ high “When Cement Australia decided to demolish the Kandos Cement Works, they asked us which parts we wanted to exhibit at the museum and the ball mill was one of them There was a plan at one stage to place the ball mill down near the railway station at the entrance to town but there were just too many safety concerns”80 tonne cement mill to become Kandos museum exhibit Ball mill (motor driven) Electrically operated For mixing and grinding purpose, with a geared motor which revolves a SS drum The drum cover has a rubber gasket to form airtight seal The speed of rotation is controllable with a single switchBall Mill Manufacturers, Ball Mill Dealers and Exporters

Christian Pfeiffer Worldwide projects

New cement ball mill circuit for Cement Australia, Plant Gladstone comprises • all equipment downstream of the cement transport to the silo • Ball mill Ø 46 х 1425 m, 5,200 kW • Separator QDK 36N with cyclones • Cement cooler СРВ 33 – 85 Capacity: up to 150 t/h Christian Pfeiffer worldwide projects A typical comparison of three competing technologies is given in Table 1, demonstrating that an efficient ball mill/thirdgeneration separator, CKP/ball mill/thirdgeneration separator and vertical mill on a typical 4000Blaine limestone cement show little overall difference in energy consumptionBest energy consumption International Cement Review HeidelbergCement completed the capacity expansion project at its cement plant in Górazdze, Poland, with the commissioning of a new cement mill The new mill, which is the largest ball mill in Europe, has a capacity of 14 million tonnes per year and ideally complements last year’s increased kiln capacity In 2012, total cement capacity in Poland rises to 56 million tonnes"With the HeidelbergCement expands cement capacity in Poland