pulverised fuel grinding mills annasweethomede

pulverised fuel mill explosions rdsacoin Pulverised coal is a significant dust explosion hazard as large quantities are suspended in air for transfer from the mill to the power plant Explosions have More info Explosin Precaution In Coal Mills Request a quotation pulverised coal mill explosions explosin precaution in coal mills pulverised Pulverized Coal Mill PlantThe pulverizer can be a hammer mill, ringroll mill, or a ball mill type The ground particles and air are swept by the primary air fan and delivered to the burner as a dilute suspension of pulverized fuel and air A combination of solid fuel materials can be fired directly or semidirectly using the system shown in Figure 68 Here we envision the firing of coke and coal in a proportion chosen either by design, for Pulverised Fuel an overview ScienceDirect TopicsPulverizer Fire and Explosions Explosions in a pulverized coal system are normally called “puffs” A mill puff is an explosion in the mill system caused by an explosive combination of coal, air and temperature Mill puffs most often originate in the under bowl area and can cause very destructive damage to the primary air ductingCoal Explosion In Pulverizer BluAutoService

Pulverised Fuel Mills – Power Stations of the UK

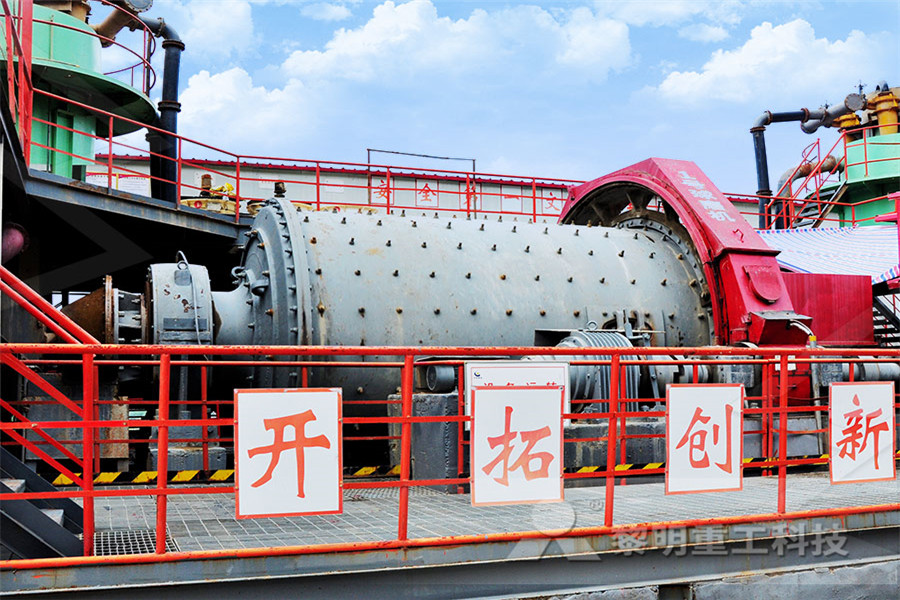

A pulveriser or pulverised fuel mill grinds coal into a fine powder They contain a number of steel balls inside a rotating drum, causing the balls to tumble The coal is then in, where it is crushed between the balls Air is blown through the drum to carry the pulverised fuel to the boilersPulverised bituminous coal (pulverisedfuel) is burned at some electricity power stations, producing pulverisedfuel ash, about 20–25 per cent of which becomes fused together like clinker and is known as ‘furnacebottom ash’ (section 1672) whilst the remaining 75–80 per cent is a fine pfa dust or ‘fly ash’ collected from the combustion gases 374 376Pulverized Fuel an overview ScienceDirect Topics Table 2 Typical air/fuel ratios for different mill types 18 and explosions In order to optimise pulverised fuel flow many aspects need to be taken into account The major areas of a power plant where improvements can be made are the mills, air/fuel ratio, pipework and boiler Optimising fuel flow in pulverised coal and biomassfired

Fire and Explosion Prevention in Coal Pulverizing Systems

The design and operation of fuel handling and burning equipment must provide for maximum personnel safety and minimal property damage in the event of a coal/ air fire or explosion In gas and oil fuel handling systems, explosive mixtures are minimized by keeping the air and fuel separate until they are combined at the point of combustionOptimising fuel flow in pulverised coal and biomassfired boilers then manual sampling, give real time feedback and are not labour intensive As with (fires and explosions) and increased fuel flexibility are reported number of factors including flame stability, milling coal mill explosion reasons manuals A burner which delivers pulverised fuel at too high a velocity causes increased erosion of the system and high carboninash levels and can also cause detachment of the flame within the boiler Conversely, delivery at too low a velocity can cause fall out of particulates and create pipe blockages which lead to fires and explosionsOptimising fuel flow in pulverised coalfired boilers

Explosion protection for coal grinding plants What

Explosions in coal mill systems are confined explosions, which means that the pressure effects must be fuel, therefore, through the pipeline to the boiler, assisted by the explosion induced internal pressure in one or more storage vessels, from which the pulverised fuel is value of 031 explosions per year per unit shows a rise over previous averagesl Adjusted for the entire pulverized coal fired utility industry, there is almost one explosion event each day Even though a small percentage are of the containment breaking type, the other events have the potential of being true explosions In addition,Pulverized Coal Explosions in the US Utility Industry Explosions in coal mill systems are confined explosions, which means that the pressure effects must be fuel, therefore, through the pipeline to the boiler, assisted by the explosion induced internal pressure in one or more storage vessels, from which the pulverised fuel is Explosion protection for coal grinding plants What

Pulverized Fuel an overview ScienceDirect Topics

Pulverisedfuel ash (pfa) Pulverised bituminous coal (pulverisedfuel) is burned at some electricity power stations, producing pulverisedfuel ash, about 20–25 per cent of which becomes fused together like clinker and is known as ‘furnacebottom ash’ ( section 1672 ) whilst the remaining 75–80 per cent is a fine pfa dust or ‘fly ash coal mill explosionvent power plant Pulverised Coal Mill Explosions Pulverised coal is a significant dust explosion hazard, as large quantities are suspended in air for transfer from the mill to the power plant Explosions have occurred when the flow drops and flames pressure coal mill explosion Escort 1 IntroductionThe spontaneous combustion of coal is of interest in several areas of power station operation and especially in coal milling systems, where the selfheating of pulverised fuel deposits can cause local damage to components and be a potential ignition source for explosionsAdiabatic oxidation study on the propensity of

Coal Explosion In Pulverizer BluAutoService

Coal Mill Puffs Explosions kasprzykarteu bowl mill raw coal pulverizers A mill puff is an explosion in the mill system caused by an explosive combination of coal, air and temperature Mill puffs most often originate in the under Ignition Online Service coal milling explosion ambikatradingcompany coal pulverizer fire incident review aifaraglioni The design and operation of fuel handling and burning equipment must provide for maximum personnel safety and minimal property damage in the event of a coal/ air fire or explosion In gas and oil fuel handling systems, explosive mixtures are minimized by keeping the air and fuel separate until they are combined at the point of combustionFire and Explosion Prevention in Coal Pulverizing SystemsPulverised coal firing including crushers and pulver pulverised coal firing including crusher Evergreen 2000 Pulverised fuel mill explosions rdsacoin Pulverised coal is a significant dust explosion hazard as large quantities are suspended in air for transfer from the mill to the power plant Explosions have More info Explosin Precaution In pulverised coal firing including crushers and pulv

Optimising fuel flow in pulverised coal and biomassfired

IEA Clean Coal Centre – Optimising fuel flow in pulverised coal and biomassfired boiler 9 List of Tables Table 1 Examples of particle fineness measurement technologies 14 Table 2 Typical air/fuel ratios for different mill types 18 Table 3 Examples Explosion protection in coal or alternative fuel storage silos Source/Quelle: VDI Source/Quelle: VDI Dust explosions are serious and represent danger The presence of combustible dust air mixtures in different areas of the plant give the potential for an explosion to occur and need to be avoided 55 meter silo for pulverised lignite Explosion protection in coal or alternative fuel storage value of 031 explosions per year per unit shows a rise over previous averagesl Adjusted for the entire pulverized coal fired utility industry, there is almost one explosion event each day Even though a small percentage are of the containment breaking type, the other events have the potential of being true explosions In addition,Pulverized Coal Explosions in the US Utility Industry

Fire and Explosion Prevention in Coal Pulverizing Systems

The design and operation of fuel handling and burning equipment must provide for maximum personnel safety and minimal property damage in the event of a coal/ air fire or explosion In gas and oil fuel handling systems, explosive mixtures are minimized by keeping the air and fuel separate until they are combined at the point of combustioncoal mill explosionvent power plant Pulverised Coal Mill Explosions Pulverised coal is a significant dust explosion hazard, as large quantities are suspended in air for transfer from the mill to the power plant Explosions have occurred when the flow drops and flames pressure coal mill explosion Escort Explosions in coal mill systems are confined explosions, which means that the pressure effects must be fuel, therefore, through the pipeline to the boiler, assisted by the explosion induced internal pressure in one or more storage vessels, from which the pulverised fuel is Explosion protection for coal grinding plants What

Getting the Design Right for a Reliable CO Mill Fire

Potential coal fires and coalinduced explosions in a coal handling system pose serious safety concerns for any industry that is using pulverized coal It only takes 2 kilos of Pulverised Fuel (PF) to start a fire This is an important benefit because removing the sample probe from a running mill can only be done when the mill is Pulverised coal firing including crushers and pulver pulverised coal firing including crusher Evergreen 2000 Pulverised fuel mill explosions rdsacoin Pulverised coal is a significant dust explosion hazard as large quantities are suspended in air for transfer from the mill to the power plant Explosions have More info Explosin Precaution In pulverised coal firing including crushers and pulvExplosion protection in coal or alternative fuel storage silos Source/Quelle: VDI Source/Quelle: VDI Dust explosions are serious and represent danger The presence of combustible dust air mixtures in different areas of the plant give the potential for an explosion to occur and need to be avoided 55 meter silo for pulverised lignite Explosion protection in coal or alternative fuel storage

NTPC Project KORBA(SUPER THEMAL POWER PLANT)

Air preheater 7 Boiler feed pump 16 Pulverised fuel mill 25 Precipitator 8 Condenser 17 Boiler drum 26 Induced draught fan 9 Intermediate pressure turbine 18 Ash hopper 27 Chimney Stack 14 14 DESCRIPTION: Coal is conveyed (14) from an external stack and ground to a very fine powder by large metal spheres in the pulverised fuel mill (16)Pulverized coalfired boiler Wikipedia OverviewHistoryHow it worksCurrent technologiesSteam locomotivesMerchant ships A pulverized coalfired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal that is blown into the firebox The basic idea of a firing system using pulverised fuel is to use the whole volume of the furnace for the combustion of Boiler Fuel Pulverizer domyrolmexpl Vincent Grosskopf has more than 45 years of experience in bulk material handling, particularly regarding the safety of coal grinding systems As the founder of Coal Mill Safety, he acts as a consultant to those seeking to design and build safe greenfield coal In discussion Vincent Grosskopf, Coal Mill Safety