DESIGN AND ANALYSIS OF IMPACT CRUSHERS

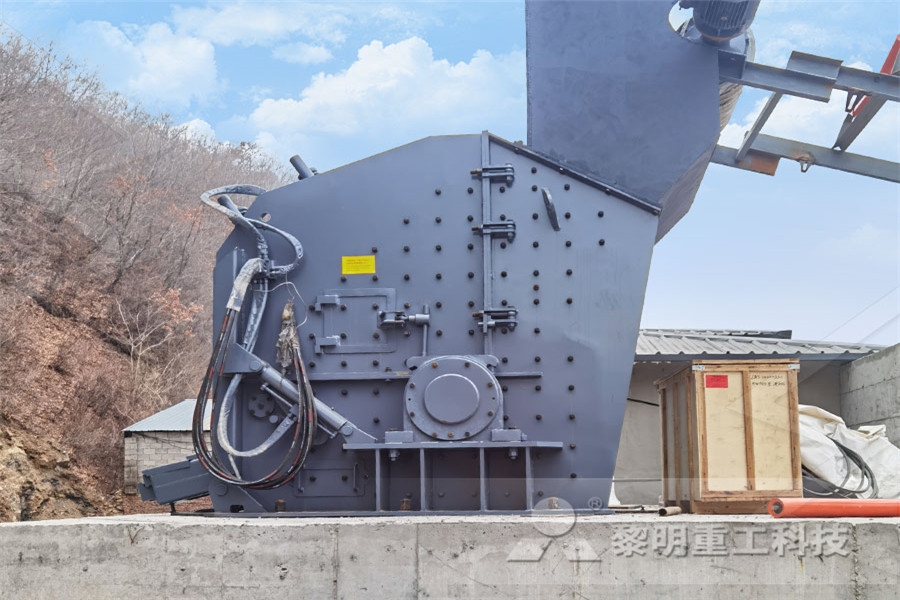

crusher,Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity Impact crushers: they involve the use of impact rather than pressure to crush has to follow these three steps: crusher selection, crusher layout and process design 24 Crushers A crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle The ore can have a size of up to 400mm There are many types of crushers but the major ones are the jaw, gyratory and the cone Design of a crushing system that improves the crushing basically of three types namely Cone crusher, Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor, hammers, casing, and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity and also do their analysisDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

DESIGN OF MECHANICAL CRUSHING MACHINE

mechanical crusher which would help to crush the used juice cans, paint cans and punched sheet metal waste This paper aims to design a crusher that could be installed anywhere and would aid crush of used wastes This paper involves the process of designing the crusher considering forces required for crushing and ergonomic The size of a jaw crusher is designated by the rectangular or square opening at the top of the jawsFor instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square Generally primary jaw crushers have the square opening design, and secondary jaw crushers have rectangular opening design“Computer Aided Design of Jaw crusher” 911 Metallurgist regarding this design and analysis This project involves processes like design, fabrication and assembling procedures Even though there are many types of the can crusher machine in the market, the completion of the new model provides a more practical usage than previous one KEYWORDS: Design Consideration, Calculation, Size Reduction, CansDesign and Fabrication of Can Crusher ijirset

Design and Fabrication of Mechanical Press for Assembly

Keywords sugarcane crusher, assembly, dismantle, fatigue, efforts, mechanical press I INTRODUCTION In India there are many industries that design, manufacture and assemble the sugarcane crusher and every industry face the similar problem related to assembly and dismantling of sugarcane crusher The following fig shows the general components or Design and Fabrication of Crusher Machine for Plastic Wastes 58 dangerous situation which could happen with human interference c Ethical Practices Ethical practices are very essential while executing the projects One has to take the responsibility to develop a product iraj DESIGN AND FABRICATION OF CRUSHER jaw crusher that employs the simple technology of a four bar mechanism, and design a small scale mechanized jaw crusher for crushing the stones into aggregates This mechanism will help to evaluate its effectiveness in comparison with other different types of mechanisms in use especially the double toggle and the modified single toggle mechanismCOLLEGE OF ARCHITECTURE AND ENGINEERING

Primary Crusher Selection Design 911 Metallurgist

How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are has to follow these three steps: crusher selection, crusher layout and process design 24 Crushers A crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle The ore can have a size of up to 400mm There are many types of crushers but the major ones are the jaw, gyratory and the cone Design of a crushing system that improves the crushing Design and Fabrication of Crusher Machine for Plastic Wastes 58 dangerous situation which could happen with human interference c Ethical Practices Ethical practices are very essential while executing the projects One has to take the responsibility to develop a product iraj DESIGN AND FABRICATION OF CRUSHER

DESIGN OF A RECYCLE BIN TIN CAN CRUSHER

іі) To design the mechanical part of a tin can crusher using CAD software Solid Work ііі) Develop the model tin can crusher using bending process, welding process, drilling process and cutting process іv) Fabricate the model tin can crusher using welding The design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid minerals for indigenous use The research work was tailored mainly on the design and production of locally fabricated rock crushing machine for indigenous useDesign and Construction of Rock Crushing Machine from [3] “Can Crusher Design In Response To Environmental Concern”, Dr Sc Kastriot A Buza, Dr Sc Shaban A Buza , Journal of Trends in the Development of Machine yard Associated Technology Vol 18, No 1, 2014, ISSN 23034009, pp 179182 [4] “The Design And Built Of Crusher Design and Fabrication of Water Bottle Crusher

TECHNICAL NOTES 5 CRUSHERS Mineral Tech

crusher can be varied in the field and some crushers are equipped with automatically controlled actuated for the automatic control of the set The open and closedside sets and the gape are identified in Figure 51 The throw of the crusher is the distance The paper deals with the Design and analysis of shaft and rotor assembly for hammer mill crusher of capacity 01 (100kg/hr) tones per hour transmitting 20 BHP and a speed of 750 rpm The design is based on the standard design procedureDesign and Analysis of Rotor Shaft Assembly of Hammer jaw crusher that employs the simple technology of a four bar mechanism, and design a small scale mechanized jaw crusher for crushing the stones into aggregates This mechanism will help to evaluate its effectiveness in comparison with other different types of mechanisms in use especially the double toggle and the modified single toggle mechanismCOLLEGE OF ARCHITECTURE AND ENGINEERING

Design and Fabrication Recycling of Plastic System

The present work en compass (design and fabrication shredder/crusher and extruder of plastic machines) the shredder/crusher of plastic machine is consisting of the four main parts; they are system drive, box, hopper and three blade rotating cutter Crushing is the process waste into smaller size approximately 05 –1cm Design The TST jaw crushers are engineered for troublefree operation, characterized by safe and easy serviceability The most modern analysis techniques and features available to date ensure a strong and reliable crusher design The TST is equipped with an efficient crushing motion, modular frame and a simple, low maintenance design to handleCrushing Systems Index Terms: Crusher, Bottle Crusher, Can Crusher, Crusher Design, Jaw Crusher —————————— —————————— 1 Introduction A crusher is a machine designed to reduce large solid material objects into a smaller volume, or smaller pieces Crushers may be used to reduce the size, or change the form, of materials so INTERNATIONAL JOURNAL OF SCIENTIFIC

Design and Development of a Plastic Bottle Crusher

plastic bottle crusher that is portable and can be installed at multiple public places, which will aid in crushing of used bottles Keywords—Crusher, Bottle Crusher, Can Crusher, Crusher Design, Jaw Crusher I INTRODUCTION A Tentative Design of the Mechanism The design process was accomplished in many stages the use of other materials to produce (Vanessa,2007)The existing Plastic bottle crusher still has many deficiencies in terms of operational and efficiency of a machine This possibility of a relatively large Hooper design, tool selection and use of the driving motor Design Hooper must THE DESIGN BUILT OF CRUSHER MACHINE PLASTIC crusher can be varied in the field and some crushers are equipped with automatically controlled actuated for the automatic control of the set The open and closedside sets and the gape are identified in Figure 51 The throw of the crusher is the distance TECHNICAL NOTES 5 CRUSHERS Mineral Tech

MASTER YOUR OUTPUT CRUSHER SELECTION QUICK

A crusher is a major investment, so it’s essential to select one with the potential to meet your needs into the future This guide covers a few of the key points to consider before making a decision But remember that your crusher is just one part of a wider process – always consider crushing in conjunction with screening and transport The paper deals with the Design and analysis of shaft and rotor assembly for hammer mill crusher of capacity 01 (100kg/hr) tones per hour transmitting 20 BHP and a speed of 750 rpm The design is based on the standard design procedureDesign and Analysis of Rotor Shaft Assembly of Hammer This comprised the design of a collection unit and crushing device ACollection Unit The pointofcare needle collection unit, comprised of a box with a lid designed to separate needle from the syringe as shown below AThe crusher part is categorized into 3 main chambers Viz are 1 Inlet chamber 2 Crushing chamber 3 Outlet chamberReference ID: R226 Design and Fabrication of a Needle

Industrial Solutions Jaw crushers ThyssenKrupp

Design characteristics • Crusher frame and swing jaw made of highgrade steel or special cast steel that has been subjected to a stress relieving heat treatment in order to pre vent residual stresses from the welding or casting process • Front and back wall reinforced The present work en compass (design and fabrication shredder/crusher and extruder of plastic machines) the shredder/crusher of plastic machine is consisting of the four main parts; they are system drive, box, hopper and three blade rotating cutter Crushing is the process waste into smaller size approximately 05 –1cmDesign and Fabrication Recycling of Plastic System Pdf Hammer Crusher Design Hammer crusher influences of design and execution of vibroprotection and machine properties on vibration intensity D Makovičkaa J Šmejkal b a Czech Technical University in Prague Klokner Institute Šol nova 7 166 08 Praha 6 Czech Republic b J Šmejkal Design of Structures L skov 10 312 16 Plzeň Czech Republic Received 5 September 2007; received Pdf Hammer Crusher Design divinechannel